In short, a modern muffle furnace performs a wide range of precise, high-temperature processes by creating a highly controlled and contaminant-free environment. Key applications include heat-treating metals through annealing and brazing, manufacturing technical ceramics and glass, sintering powdered metals, and performing critical analytical procedures like ashing samples for quality control or research.

The true value of a muffle furnace is not just its ability to get hot, but its ability to isolate a material from combustion byproducts and heating elements. This separation—the "muffle"—is what enables the precise, repeatable, and clean results required for advanced manufacturing and scientific analysis.

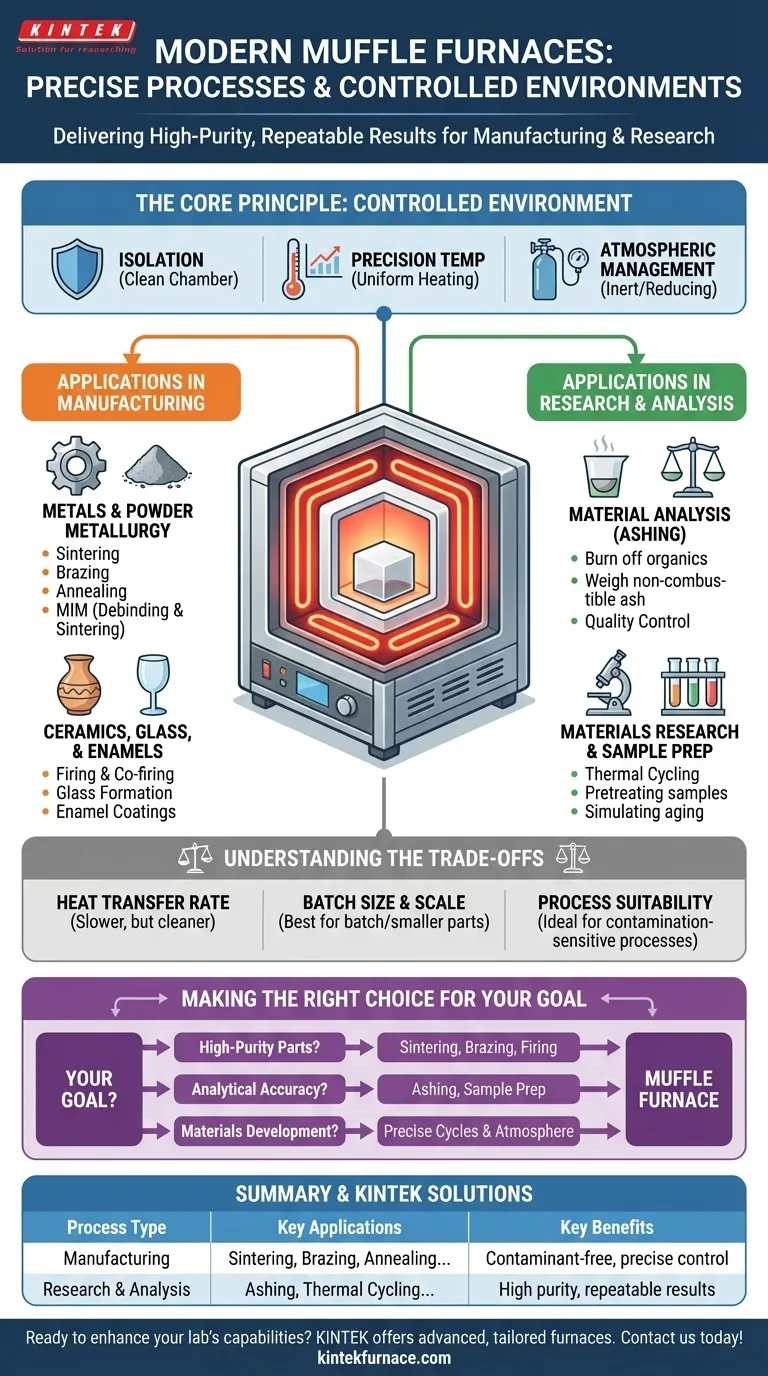

The Core Principle: A Controlled Environment

A muffle furnace's capabilities stem from its fundamental design. Understanding this design is key to understanding its applications. It is not simply an oven; it is a controlled-atmosphere instrument.

What "Muffle" Means: Isolation from Contaminants

The defining feature is the muffle, an inner chamber that contains the workpiece. This chamber is heated from the outside by heating coils.

This design separates the material being heated from any potential contaminants produced by fuel combustion or the heating elements themselves. The result is an exceptionally clean heating process.

Precision Temperature Control

Modern furnaces offer superior temperature uniformity, ensuring the entire workpiece is heated evenly.

They allow for precise programming of thermal cycles, including controlled ramping (rate of temperature increase), soaking (holding at a specific temperature), and cooling. Advanced models feature multiple control zones for even greater accuracy.

Atmospheric Management

Many advanced muffle furnaces can control the atmosphere inside the chamber. This allows for processes that must occur in an inert gas or a specific environment, such as reducing operations that prevent oxidation.

Key Applications in Manufacturing

The combination of high heat, cleanliness, and control makes muffle furnaces essential for producing high-value materials where consistency and purity are non-negotiable.

Metals and Powder Metallurgy

These furnaces are central to forming and treating metal parts.

Key processes include:

- Sintering: Heating compressed metal powders below their melting point to bond them into a solid piece.

- Brazing: Joining two pieces of metal using a filler metal, which requires clean surfaces and precise temperature.

- Annealing: Heating and slowly cooling metal to reduce hardness and increase ductility.

- Metal Injection Molding (MIM): A two-part process involving debinding (removing a polymer binder) followed by sintering to create the final, dense metal part.

Ceramics, Glass, and Enamels

The ability to achieve very high, uniform temperatures is critical for these materials.

Common uses are:

- Firing & Co-firing: Firing technical ceramics to achieve desired density and mechanical properties.

- Glass Formation: Melting raw materials to create specialized glass or reforming existing glass.

- Enamel Coatings: Fusing enamel powders onto a substrate to create a hard, protective layer.

Applications in Research and Analysis

In a laboratory setting, the furnace's role shifts from production to analysis, where removing all variables except temperature is paramount.

Material Analysis (Ashing)

The most common analytical use is ashing. This involves heating a sample to burn off all organic and combustible substances.

What remains is the non-combustible ash content, which can be weighed and analyzed. This is a standard quality control procedure in industries from food science to wastewater management.

Materials Research and Sample Prep

Researchers use muffle furnaces to test material properties under extreme thermal stress (thermal cycling) or to prepare samples for further analysis.

Specialized applications include pretreating medical samples, simulating aging processes, and even research into the disposal of nuclear fuel materials.

Understanding the Trade-offs

While powerful, muffle furnaces are not a universal solution. Objectivity requires acknowledging their limitations.

Heat Transfer Rate

Because heat is transferred indirectly via radiation and convection, heating can be slower compared to a furnace where a flame directly contacts the material. This is the trade-off for a cleaner environment.

Batch Size and Scale

Traditional muffle furnaces are best suited for batch processes or smaller parts. While continuous, automated "pusher" systems exist for larger-scale production, they represent a significant increase in complexity and cost.

Process Suitability

The isolated environment is the primary benefit. If a process is not sensitive to contamination from direct heating and only requires high heat, a simpler, less expensive type of furnace may be more appropriate.

Making the Right Choice for Your Goal

To determine if a muffle furnace is the right tool, focus on the required outcome of your process.

- If your primary focus is manufacturing high-purity parts: The isolation from contaminants during processes like sintering, brazing, and ceramics firing is the key benefit.

- If your primary focus is analytical accuracy: The furnace's ability to perform complete combustion for ashing or sample prep without introducing external contaminants is essential.

- If your primary focus is materials development: The precise control over temperature cycles and atmosphere makes it an indispensable tool for testing and creating new materials.

Ultimately, choosing a muffle furnace is a decision to prioritize control and purity in a high-temperature environment.

Summary Table:

| Process Type | Key Applications | Key Benefits |

|---|---|---|

| Manufacturing | Sintering, Brazing, Annealing, Ceramics Firing | Contaminant-free environment, precise temperature control |

| Research & Analysis | Ashing, Thermal Cycling, Sample Preparation | High purity, repeatable results for accurate analysis |

Ready to enhance your lab's capabilities with a tailored high-temperature furnace solution? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization ensures they meet your unique experimental needs for superior performance in manufacturing, research, and quality control. Contact us today to discuss how we can support your specific processes!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity