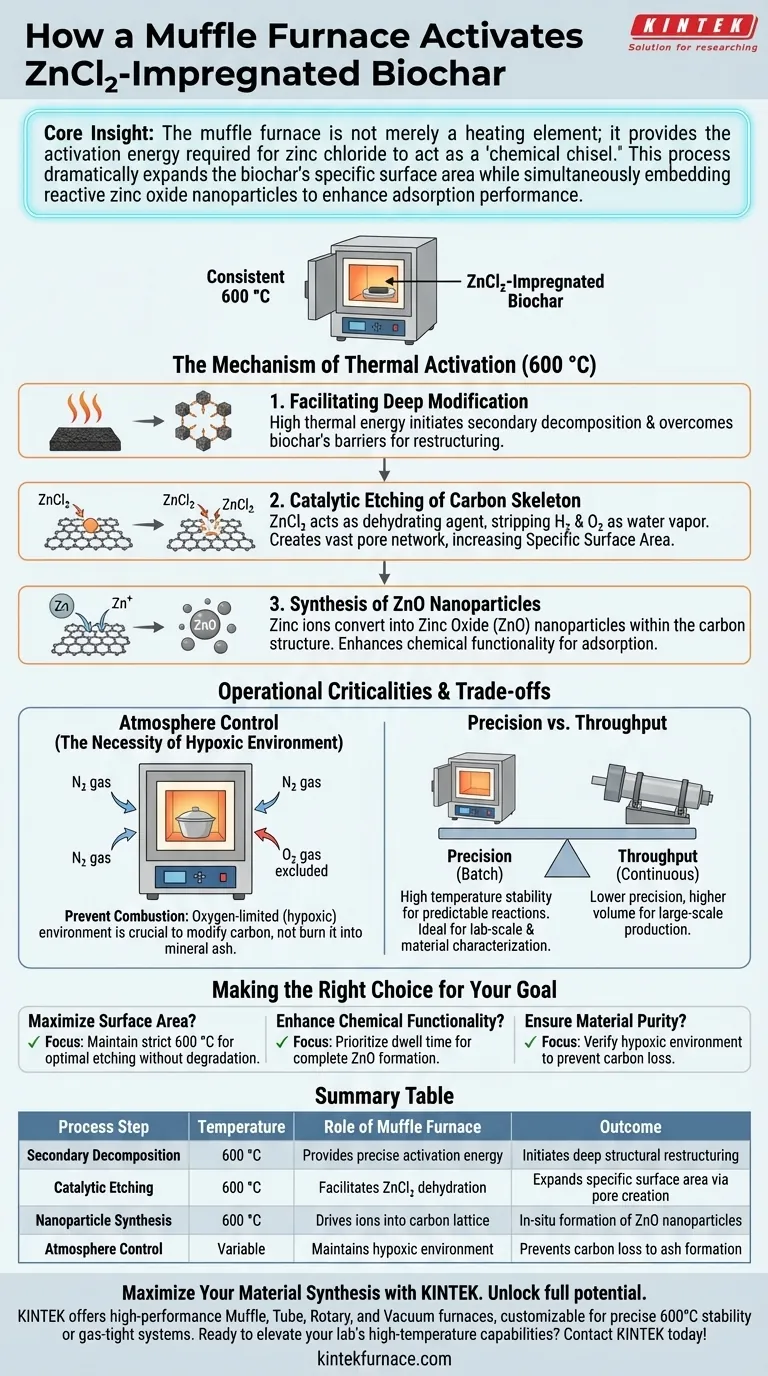

During the secondary thermal decomposition of zinc chloride-impregnated biochar, a muffle furnace functions as a precise high-temperature reactor that facilitates deep chemical modification. It maintains a consistent environment of 600 °C, which drives the zinc chloride to catalytically etch the carbon skeleton and synthesize zinc oxide (ZnO) nanoparticles within the material's structure.

Core Insight: The muffle furnace is not merely a heating element; it provides the activation energy required for zinc chloride to act as a "chemical chisel." This process dramatically expands the biochar's specific surface area while simultaneously embedding reactive zinc oxide nanoparticles to enhance adsorption performance.

The Mechanism of Thermal Activation

Facilitating Deep Modification

The primary role of the muffle furnace in this specific phase is to subject the impregnated biochar to a steady temperature of 600 °C.

This high thermal energy is required to initiate the secondary decomposition of the biochar substrate. At this temperature, the physical and chemical barriers of the biomass are overcome, allowing for substantial structural restructuring.

Catalytic Etching of the Carbon Skeleton

Within this heated environment, the impregnated zinc chloride ($ZnCl_2$) transitions from a passive additive to an active dehydrating and catalytic agent.

The heat enables the zinc chloride to attack the carbon framework. It effectively "etches" the carbon skeleton, stripping away hydrogen and oxygen atoms in the form of water vapor.

This etching process creates a vast network of pores, resulting in a significant increase in the specific surface area of the biochar.

Synthesis of Zinc Oxide Nanoparticles

Beyond physical etching, the muffle furnace facilitates a critical chemical transformation involving zinc ions.

The thermal energy drives zinc ions into the carbon lattice structure. Under these specific conditions, these ions convert into zinc oxide (ZnO) nanoparticles.

The presence of these nanoparticles is vital, as they introduce new chemical functionality to the biochar, significantly improving its ability to adsorb contaminants.

Operational Criticalities and Trade-offs

The Necessity of Atmosphere Control

While the primary goal is activation, a common pitfall in using muffle furnaces is the inadvertent combustion of the sample.

As noted in standard ash analysis procedures, operating a muffle furnace with abundant oxygen at high temperatures (e.g., 550 °C) will burn away organic matter entirely, leaving only mineral ash.

Therefore, for activation rather than ash testing, the furnace must maintain an oxygen-limited (hypoxic) environment. This is often achieved using gas-tight retorts or covered crucibles to ensure the carbon skeleton is modified, not destroyed.

Precision vs. Throughput

Muffle furnaces offer excellent temperature precision and stability, which is essential for ensuring the zinc chloride reacts predictably at exactly 600 °C.

However, they are typically batch-process units with limited volume. This makes them ideal for laboratory-scale precision and material characterization but potentially less efficient for continuous, large-scale production compared to rotary kilns.

Making the Right Choice for Your Goal

To maximize the utility of a muffle furnace for biochar applications, consider your specific objective:

- If your primary focus is surface area expansion: Ensure the temperature is strictly maintained at 600 °C to maximize the etching potential of the zinc chloride without degrading the carbon structure.

- If your primary focus is chemical functionality: Prioritize the dwell time to allow sufficient thermal energy for the complete formation and integration of zinc oxide (ZnO) nanoparticles.

- If your primary focus is material purity: verify that the furnace environment is hypoxic to prevent the loss of carbon yield to ash formation.

The muffle furnace is the critical tool that transforms raw biochar from a simple carbon structure into a highly reactive, nanoparticle-enhanced adsorbent.

Summary Table:

| Process Step | Temperature | Role of Muffle Furnace | Outcome |

|---|---|---|---|

| Secondary Decomposition | 600 °C | Provides precise activation energy | Initiates deep structural restructuring |

| Catalytic Etching | 600 °C | Facilitates ZnCl2 dehydration | Expands specific surface area via pore creation |

| Nanoparticle Synthesis | 600 °C | Drives ions into carbon lattice | In-situ formation of ZnO nanoparticles |

| Atmosphere Control | Variable | Maintains hypoxic environment | Prevents carbon loss to ash formation |

Maximize Your Material Synthesis with KINTEK

Unlock the full potential of your biochar activation and chemical modification processes. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, and Vacuum furnaces—all customizable to meet your specific research or production needs. Whether you require precise 600°C stability for catalytic etching or gas-tight systems for hypoxic activation, our equipment delivers the reliability your lab demands.

Ready to elevate your lab's high-temperature capabilities? Contact KINTEK today for a tailored solution!

Visual Guide

References

- Muradiye Şahin, Ronaldo Câmara Cozza. Removal of Primamycin La from Milk Sample Using ZnCl2-Activated Biochar Prepared from Bean Plant as Adsorbent: Kinetic and Equilibrium Calculations. DOI: 10.3390/pr13010230

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does a Muffle Furnace play in biomass pellet torrefaction? Optimize Your High-Temperature Processing

- How does a high-performance sintering furnace influence KNN-based ceramics? Master Microstructure & Precision

- What is a muffle furnace and what are its primary functions? Unlock Contamination-Free High-Temperature Processing

- How does a high-temperature box resistance furnace contribute to the synthesis of silicon-doped ruthenium dioxide catalysts?

- What is the function of a Muffle Furnace in the pre-treatment of Ni-Fe-Cu alloy anodes? Achieve Superior Corrosion Resistance

- Why is the temperature control of a muffle furnace critical for ZnO nanomaterials? Achieve Optimal ZnO Calcination

- How do you maintain a muffle furnace? Ensure Longevity and Safety with Proven Tips

- How does a muffle furnace contribute to CRP thermal treatment? Unlock High Reactivity in Recycled Powder