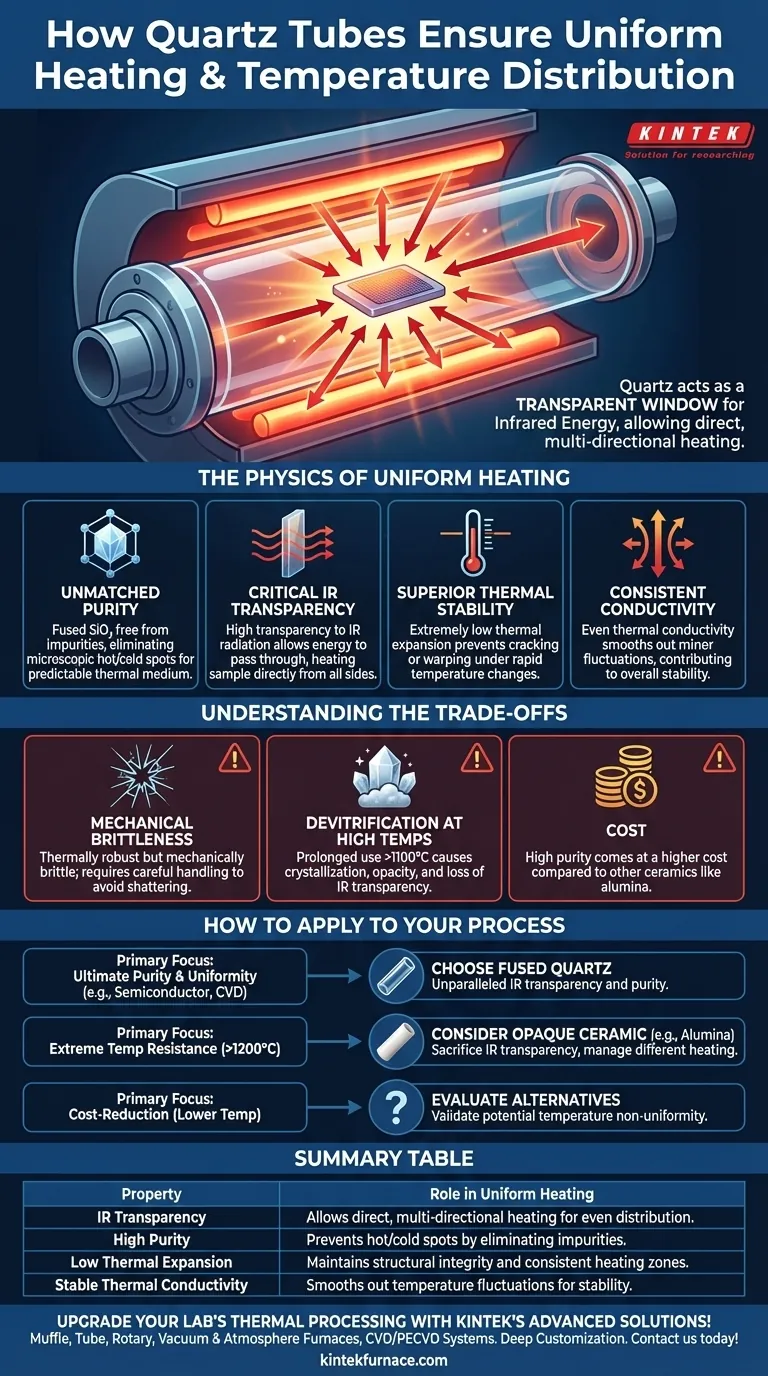

At its core, a quartz tube ensures uniform heating through a unique combination of extreme material purity and a high transparency to infrared (IR) radiation. Unlike opaque materials that block heat and create surface temperature gradients, quartz allows thermal energy to pass directly through its walls to the target sample. This direct, multi-directional heating is the primary reason for its superior temperature uniformity.

The key insight is that quartz is not just a passive container. It is an active component in the heating process, acting as a transparent window for the infrared energy that does the primary work, ensuring the sample is heated evenly from all sides simultaneously.

The Physics of Uniform Heating in Quartz

To understand why quartz excels, we must look beyond simple heat conduction and examine its fundamental material properties. It's the interplay of these properties that makes it the standard for high-precision thermal processes.

Unmatched Purity and Structural Integrity

Fused quartz is essentially pure silicon dioxide (SiO₂), free from the impurities found in other ceramics or glasses. Impurities can create microscopic hot or cold spots within a material, leading to uneven heat distribution. The homogeneity of quartz eliminates this variable, providing a predictable and uniform thermal medium.

The Critical Role of Infrared (IR) Transparency

This is the most important factor. In a typical tube furnace, the heating elements glow hot, emitting vast amounts of energy as infrared radiation. Quartz is highly transparent to a wide spectrum of this IR light.

Instead of just heating the outer surface of the tube, the radiation passes straight through the quartz wall. This energy then directly heats the atmosphere and the sample inside the tube from all directions. The tube itself is heated more gently by a combination of absorbed radiation and convection from the inside, creating a stable thermal boundary.

Superior Thermal Stability

Quartz has an extremely low coefficient of thermal expansion. This means it barely expands or contracts when its temperature changes dramatically. This resistance to thermal shock prevents the material from cracking or warping during rapid heating or cooling cycles, preserving its structural integrity and ensuring the heating zone remains consistent.

Consistent Thermal Conductivity

While quartz is not a great thermal conductor like a metal, its conductivity is very consistent across the material. Any heat that is absorbed by the tube wall is distributed evenly throughout its structure, which helps to smooth out any minor fluctuations from the heating elements and contributes to the overall temperature stability.

Understanding the Trade-offs

No material is perfect. Acknowledging the limitations of quartz is critical for its proper use and for understanding when an alternative might be necessary.

Mechanical Brittleness

While thermally robust, quartz is a glass. It is mechanically brittle and can shatter from a physical impact or improper mounting that creates stress points. It requires careful handling.

Devitrification at High Temperatures

When held at very high temperatures (typically above 1100°C) for extended periods, quartz can begin to crystallize in a process called devitrification. This causes it to become opaque and lose its IR transparency, compromising its uniform heating capabilities and increasing its susceptibility to thermal shock.

Cost

High-purity fused quartz is significantly more expensive than other ceramic materials like alumina. The cost is a direct trade-off for its exceptional purity and thermal performance.

How to Apply This to Your Process

Your choice of material must align with the specific demands of your application.

- If your primary focus is ultimate purity and uniformity (e.g., semiconductor processing, CVD): The unparalleled IR transparency and purity of fused quartz make it the only logical choice.

- If your primary focus is extreme temperature resistance above 1200°C: You may need to consider an opaque ceramic like high-purity Alumina, but you will sacrifice IR transparency and must design the process to manage a different heating dynamic.

- If your primary focus is cost-reduction for a lower-temperature process: You might evaluate other materials, but be prepared to validate that the resulting temperature non-uniformity does not negatively impact your results.

Understanding that quartz acts as a window for heat, not a barrier, empowers you to optimize your high-temperature processes for maximum precision and repeatability.

Summary Table:

| Property | Role in Uniform Heating |

|---|---|

| IR Transparency | Allows direct, multi-directional heating of samples for even temperature distribution |

| High Purity | Prevents hot/cold spots by eliminating impurities |

| Low Thermal Expansion | Maintains structural integrity and consistent heating zones |

| Stable Thermal Conductivity | Smooths out temperature fluctuations for better stability |

Upgrade your lab's thermal processing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, such as achieving uniform heating in quartz tube applications. Contact us today to discuss how we can enhance your precision and efficiency!

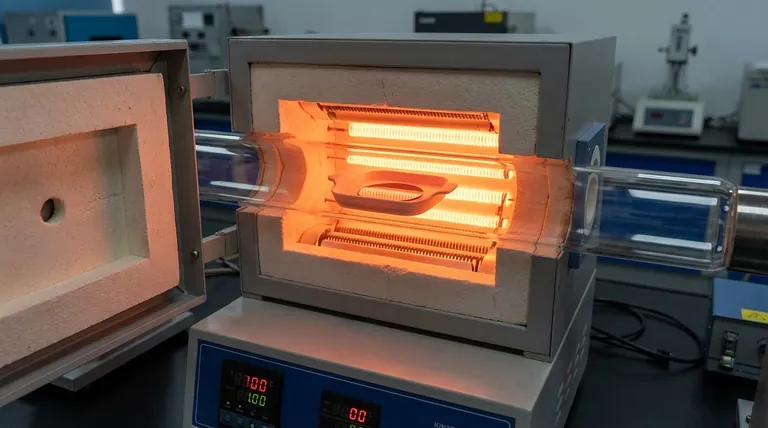

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is a quartz tube furnace and what is its primary use? Essential for Controlled High-Temp Processing

- How does the work process of a quartz tube furnace typically proceed? Master Precision Heating for Advanced Materials

- What factors should be considered when purchasing a quartz tube furnace? Ensure Reliable High-Temperature Processing

- What technical requirements affect the external thermal strength of furnace tubes? Optimize for High-Temp Performance

- What is a Quartz Tube Furnace and what is its primary function? Essential for Real-Time Material Observation