Industrial vacuum and atmosphere furnaces facilitate a critical microstructural transformation in Inconel 718 components produced via Wire Arc Additive Manufacturing (WAAM). By executing precise heat treatment programs, these furnaces dissolve harmful phases formed during the printing process and induce the precipitation of strengthening elements. This converts the material from a variable, as-deposited state into a uniform, high-strength alloy.

The core function of these furnaces is to correct the mechanical anisotropy and microstructural defects inherent to the WAAM process. By providing a uniform thermal field, they convert brittle Laves phases into strengthening gamma precipitates, ensuring the final part achieves the necessary tensile strength and durability.

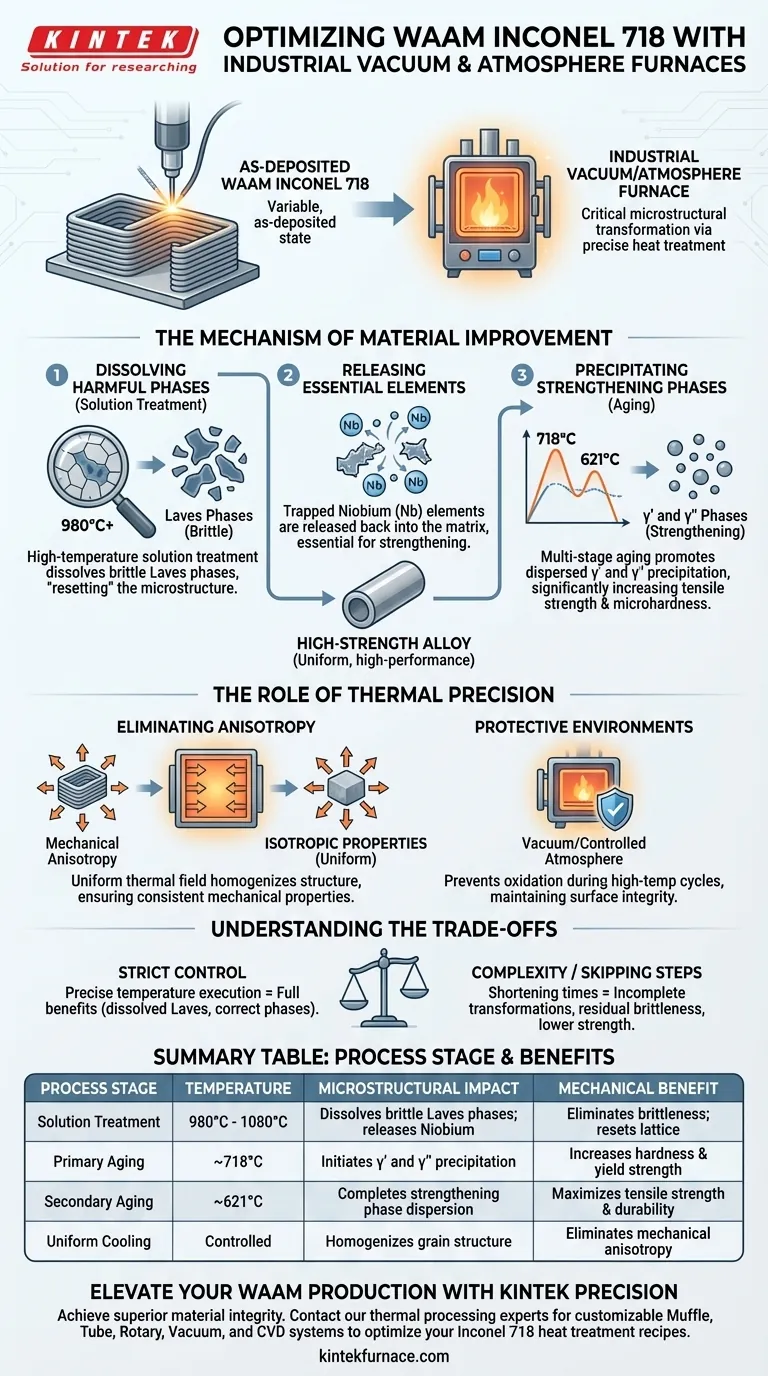

The Mechanism of Material Improvement

Dissolving Harmful Phases

In the as-deposited state, WAAM-produced Inconel 718 often contains Laves phases. These are brittle intermetallic compounds that can severely limit the material's mechanical performance.

Industrial furnaces utilize high-temperature solution treatments (often around 980°C or higher) to facilitate the dissolution of these harmful phases. This process effectively "resets" the microstructure, preparing the lattice for strengthening.

Releasing Essential Elements

When Laves phases are dissolved, they release trapped niobium elements back into the matrix. This release is critical because niobium is the key ingredient required for the formation of strengthening phases.

Without this high-temperature homogenization, the niobium remains locked in brittle structures, rendering the alloy weaker than its potential.

Precipitating Strengthening Phases

Once the niobium is released, the furnace executes a multi-stage aging process, typically at temperatures of 718°C and 621°C.

This controlled cooling and holding promotes the dispersed precipitation of gamma prime ($\gamma'$) and gamma double prime ($\gamma''$) phases. These precipitates act as the primary reinforcement mechanism, significantly increasing the tensile strength and microhardness of the material.

The Role of Thermal Precision

Eliminating Anisotropy

WAAM processes naturally create mechanical anisotropy, meaning the material is stronger in one direction than another due to layer-by-layer deposition.

Furnaces capable of generating a uniform thermal field are essential to homogenize the structure. This ensures that mechanical properties become consistent (isotropic) throughout the entire component, regardless of the printing direction.

Protective Environments

Industrial vacuum or atmosphere furnaces provide a controlled environment that prevents oxidation during these high-temperature cycles.

This protection is vital for maintaining surface integrity while the material undergoes the rigorous solution and aging treatments required to optimize the Inconel 718 lattice.

Understanding the Trade-offs

The Necessity of Strict Control

The benefits of heat treatment are entirely dependent on precise temperature control. A furnace that cannot maintain exact temperatures or uniform distribution will fail to fully dissolve Laves phases or precipitate the gamma phases correctly.

Complexity of Cycle Management

Optimizing Inconel 718 is not a single-step process; it requires a complex recipe of solution treatment followed by two-stage aging.

Skipping steps or shortening holding times to save energy can lead to incomplete phase transformations, leaving the material with residual brittleness or lower compressive strength.

Making the Right Choice for Your Goal

To maximize the performance of your WAAM Inconel 718 parts, align your heat treatment strategy with your specific mechanical requirements:

- If your primary focus is eliminating brittleness: Prioritize the solution treatment phase (e.g., 980°C–1080°C) to ensure the complete dissolution of harmful Laves phases.

- If your primary focus is maximum tensile strength: rigorous adherence to the two-stage aging process (718°C and 621°C) is required to drive the precipitation of $\gamma'$ and $\gamma''$ phases.

True material performance in additively manufactured Inconel 718 is not defined during printing, but solidified during the precise thermal cycles that follow.

Summary Table:

| Process Stage | Temperature Range | Microstructural Impact | Mechanical Benefit |

|---|---|---|---|

| Solution Treatment | 980°C - 1080°C | Dissolves brittle Laves phases; releases Niobium | Eliminates brittleness; resets lattice |

| Primary Aging | ~718°C | Initiates $\gamma'$ and $\gamma''$ precipitation | Increases hardness and yield strength |

| Secondary Aging | ~621°C | Completes strengthening phase dispersion | Maximizes tensile strength and durability |

| Uniform Cooling | Controlled | Homogenizes grain structure | Eliminates mechanical anisotropy |

Elevate Your WAAM Production with KINTEK Precision

Don't let mechanical anisotropy or brittle Laves phases compromise your Inconel 718 components. KINTEK provides the thermal precision necessary to transform as-deposited materials into high-performance alloys. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific heat treatment recipes.

Whether you need to optimize tensile strength or ensure uniform material properties, our high-temperature lab furnaces deliver the exact thermal fields required for critical solution and aging cycles.

Ready to achieve superior material integrity? Contact our thermal processing experts today to find the perfect furnace solution for your additive manufacturing needs.

Visual Guide

References

- V. Santhosh, N. Hari Babu. A Study on Microstructure and Mechanical Properties of Inconel 718 Superalloy Fabricated by Novel CMT-WAAM Process. DOI: 10.1590/1980-5373-mr-2023-0258

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What protective role does a constant flow of inert gas play in dynamic atmosphere sintering? Enhance Material Integrity

- What additional functionalities does an atmosphere furnace offer compared to a muffle furnace? Unlock Advanced Material Processing

- Why is it necessary to use a high-temperature furnace to pre-fire porous alumina substrates for alloy wettability?

- What is the function of a high-temperature annealing furnace for Al-7075? Optimize Ductility and Microstructure

- What are the applications of an atmosphere box furnace in environmental protection? Safely Treat Hazardous Waste with Precision

- What are the key components of an atmosphere furnace? Essential Parts for Controlled Heat Treatment

- What is the main purpose of introducing a reducing atmosphere in sintering? Optimize Metal Bonding & Strength

- Which industries commonly use inert ovens? Essential for Electronics, Metallurgy, and Materials Science