In environmental protection, an atmosphere box furnace is primarily used for the high-temperature treatment of hazardous materials in a precisely controlled gaseous environment. This technology enables the safe thermal decomposition of hazardous waste, high-temperature disinfection of medical waste, and the abatement of certain industrial pollutants by breaking them down into less harmful or inert substances.

The true value of an atmosphere box furnace in environmental applications is not just its high heat, but its ability to control the internal atmosphere. This control ensures hazardous materials are broken down completely and safely, preventing the formation of more dangerous byproducts.

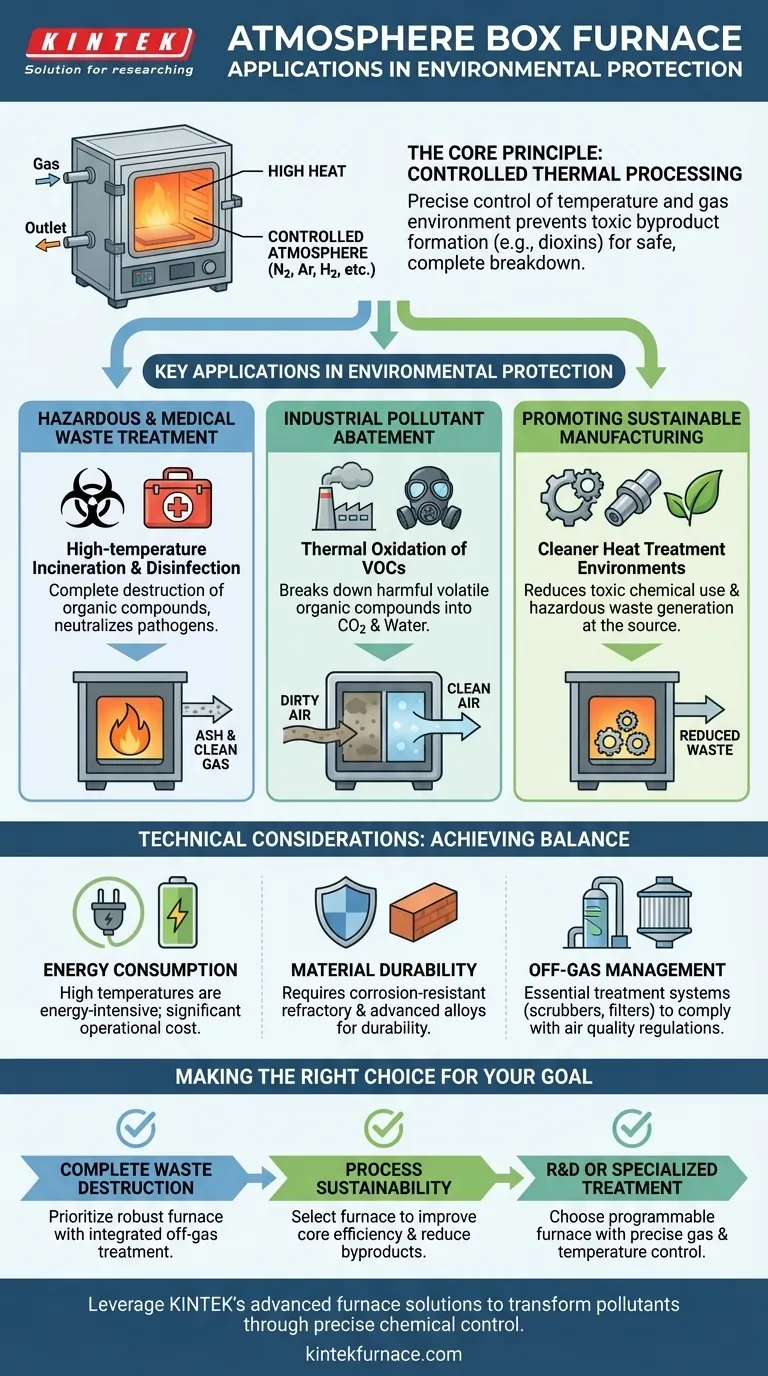

The Core Principle: Controlled Thermal Processing

To understand the applications, you must first understand the core technology. It's the combination of extreme heat and atmospheric control that makes this furnace a powerful environmental tool.

What is an Atmosphere Box Furnace?

An atmosphere box furnace is an enclosed chamber capable of achieving high temperatures while maintaining a specific, managed gas environment.

Instead of operating in ambient air, it uses specific gases like inert nitrogen or argon to prevent oxidation, or reducing gases like hydrogen to promote certain chemical reactions. This control is the furnace's defining feature.

Why a Controlled Atmosphere is Critical

In environmental treatment, simply burning waste can create toxic byproducts like dioxins and furans. A controlled atmosphere prevents these unwanted reactions.

By carefully managing the gas inside the furnace—for example, by ensuring an oxygen-rich environment for complete combustion or an oxygen-starved one for pyrolysis—operators can dictate the exact chemical breakdown of the waste material.

Key Applications in Environmental Protection

The furnace's ability to precisely manage thermal decomposition makes it suitable for several critical environmental tasks.

Hazardous and Medical Waste Treatment

For hazardous materials, the furnace is used for high-temperature incineration. The extreme heat, combined with a controlled oxygen supply, ensures the complete destruction of organic compounds, converting them into stable, harmless substances like ash and flue gas.

Similarly, it can be used for the high-temperature disinfection and sterilization of medical waste, neutralizing pathogens and preventing the spread of disease before final disposal.

Industrial Pollutant Abatement

The furnace can be applied to treat industrial waste streams. For example, it can be used in the thermal oxidation of volatile organic compounds (VOCs) from industrial exhaust gases.

Passing polluted air through a high-temperature chamber breaks down these harmful compounds into carbon dioxide and water, significantly reducing air pollution.

Promoting Sustainable Manufacturing

Beyond "end-of-pipe" treatment, atmosphere furnaces contribute to sustainability by improving manufacturing processes.

By creating cleaner heat treatment environments for metals, they can reduce or eliminate the need for toxic chemicals and cut down on hazardous waste generation at the source, leading to a more sustainable overall process.

Understanding the Technical Considerations

While powerful, an atmosphere furnace is not a universal solution. Its effective implementation depends on understanding its operational demands and limitations.

Energy Consumption

Achieving and maintaining the high temperatures required for waste destruction is highly energy-intensive. The energy cost is a significant factor in the operational budget and overall environmental footprint of the facility.

Material Durability and Cost

The furnace's internal chamber must withstand extreme temperatures and potentially corrosive substances released from waste materials. This requires specialized construction with corrosion-resistant refractory bricks and advanced alloys, increasing the initial investment cost.

Off-Gas Management

The thermal decomposition process generates exhaust gases that must be treated before being released into the atmosphere. A complete system requires scrubbers, filters, and monitoring equipment to ensure it complies with air quality regulations. The furnace itself is only one part of the solution.

Making the Right Choice for Your Goal

To apply this technology effectively, align the furnace's capabilities with your specific environmental objective.

- If your primary focus is complete waste destruction: Prioritize a furnace system designed for high-temperature incineration with a robust, integrated off-gas treatment system.

- If your primary focus is process sustainability: Select a furnace that improves your core manufacturing efficiency, reducing the generation of hazardous byproducts from the start.

- If your primary focus is R&D or specialized treatment: A programmable furnace with precise control over temperature and multiple gas inputs will provide the flexibility needed for developing new environmental solutions.

Ultimately, leveraging an atmosphere box furnace empowers you to transform harmful pollutants into manageable substances through precise chemical control.

Summary Table:

| Application | Key Function | Benefits |

|---|---|---|

| Hazardous and Medical Waste Treatment | High-temperature incineration and disinfection | Complete destruction of organic compounds, neutralizes pathogens |

| Industrial Pollutant Abatement | Thermal oxidation of VOCs | Reduces air pollution by breaking down harmful compounds |

| Sustainable Manufacturing | Clean heat treatment for metals | Reduces toxic chemical use and hazardous waste generation |

Ready to enhance your environmental protection efforts with advanced furnace solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with high-temperature furnace solutions tailored for hazardous waste treatment, pollution control, and sustainable processes. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities to precisely meet your unique experimental and operational needs. Contact us today to discuss how our furnaces can deliver precise thermal processing, improve safety, and support your environmental goals!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling