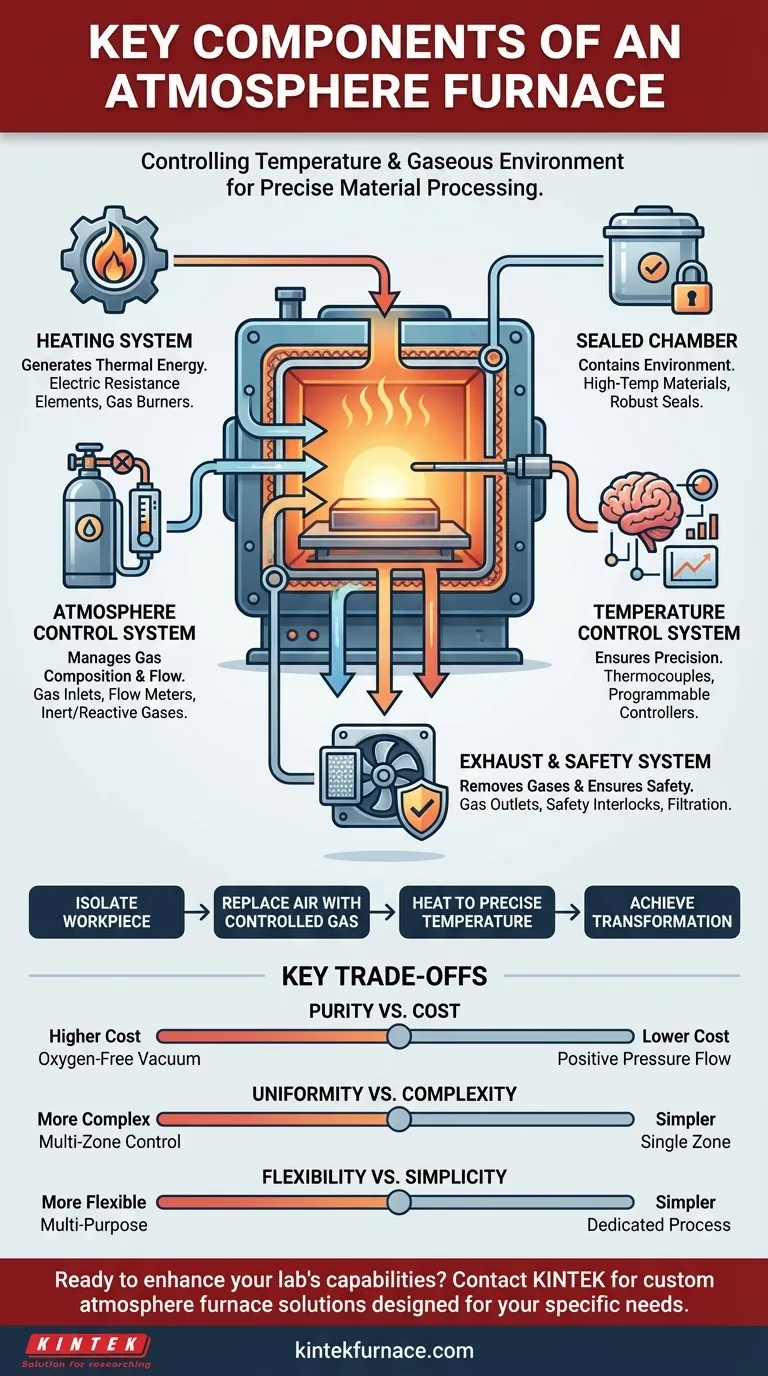

At its core, an atmosphere furnace is a system of five interconnected components designed to control both temperature and the gaseous environment around a material. These key parts are the heating system, a sealed process chamber, an atmosphere control system for managing gases, a temperature control system for precision, and an exhaust or safety system. Together, they create a highly controlled environment to achieve specific metallurgical or chemical outcomes.

An atmosphere furnace is not merely a box that gets hot. It is a precise environmental chamber where the composition of the gas is as critical as the temperature. Understanding how its core components interact is the key to preventing unwanted reactions like oxidation or deliberately altering a material's surface properties.

How the Core Components Function Together

An atmosphere furnace works by isolating a workpiece from the ambient air and replacing it with a specific, controlled gas mixture. This environment is then heated to a precise temperature for a set duration to achieve a desired material transformation.

The Heating System: Generating Thermal Energy

The heating system is the engine of the furnace, responsible for generating the required thermal energy. Its design directly impacts temperature uniformity and ramp-up speed.

Most modern furnaces use electric resistance heating elements, such as wires or plates made from specialized alloys. Some industrial-scale applications may still utilize gas burners.

The Sealed Chamber: Containing the Environment

The chamber is the vessel that holds both the workpiece and the controlled atmosphere. Its primary job is to be an effective barrier against the outside world.

This chamber is built from high-temperature-resistant materials and incorporates robust sealing mechanisms on all doors and ports. A perfect seal is crucial for preventing oxygen contamination and maintaining the purity of the internal atmosphere.

The Atmosphere Control System: Defining the Process

This is the defining system of an atmosphere furnace. It manages the introduction, composition, and flow rate of the process gases.

It consists of gas inlets, flow meters or controllers, and sometimes gas mixers. This system allows the operator to use inert gases (like Nitrogen or Argon) to prevent reactions or reactive gases (like Hydrogen or Carbon Monoxide) to intentionally change the material's surface chemistry.

The Temperature Control System: Ensuring Precision

This system acts as the furnace's brain, ensuring the thermal cycle is executed with high accuracy and repeatability.

It relies on sensors, typically thermocouples, placed within the chamber to measure the temperature. This data is fed to a programmable controller, which modulates power to the heating elements to follow a pre-set temperature profile precisely.

The Exhaust and Safety System: Maintaining Stability

This system safely removes used process gases from the chamber and handles any abnormal conditions.

It includes gas outlets and, in some cases, filtration or afterburner systems to treat the exhaust. Critically, it also includes safety interlocks that monitor gas flow, pressure, and temperature to protect both the operator and the equipment.

Understanding the Key Trade-offs

Selecting or operating an atmosphere furnace involves balancing competing priorities. Your process requirements will dictate where you must invest in performance.

Purity vs. Cost

Achieving a truly oxygen-free environment requires a vacuum-tight chamber and high-purity gases, which significantly increases cost. For many applications, maintaining a slight positive pressure with a continuous gas flow is sufficient to prevent most air ingress, offering a practical compromise.

Temperature Uniformity vs. Complexity

A simple furnace with a single heating zone may have significant temperature variations across the chamber. Achieving high temperature uniformity requires multiple, independently controlled heating zones and sophisticated controller logic, adding to the furnace's complexity and price.

Flexibility vs. Simplicity

A furnace dedicated to a single process, like annealing in nitrogen, can have a very simple atmosphere system. A multi-purpose furnace capable of handling inert, reducing, and oxidizing atmospheres requires a far more complex and costly gas management and safety system.

Making the Right Choice for Your Goal

The ideal furnace configuration depends entirely on the material process you need to perform. Understanding the function of each component allows you to specify a system that meets your technical requirements without unnecessary expense.

- If your primary focus is preventing oxidation: Prioritize a furnace with excellent sealing mechanisms and a reliable inert gas (N₂, Ar) delivery system.

- If your primary focus is altering surface chemistry (e.g., carburizing): You need a precise atmosphere control system capable of accurately mixing and controlling reactive gases.

- If your primary focus is high-precision heat treatment: Invest in an advanced temperature control system with multiple measurement zones and a programmable controller for maximum uniformity and repeatability.

By viewing the furnace as an integrated system, you can control your material's processing environment with confidence and precision.

Summary Table:

| Component | Key Function | Common Features |

|---|---|---|

| Heating System | Generates thermal energy | Electric resistance elements, gas burners |

| Sealed Chamber | Contains the controlled environment | High-temperature materials, robust seals |

| Atmosphere Control System | Manages gas composition and flow | Gas inlets, flow meters, inert/reactive gases |

| Temperature Control System | Ensures precise thermal cycles | Thermocouples, programmable controllers |

| Exhaust and Safety System | Removes gases and ensures safety | Gas outlets, safety interlocks, filtration |

Ready to enhance your lab's capabilities with a custom atmosphere furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by deep customization for precise experimental requirements. Contact us today to discuss how our expertise can optimize your material processing and drive innovation in your laboratory!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing