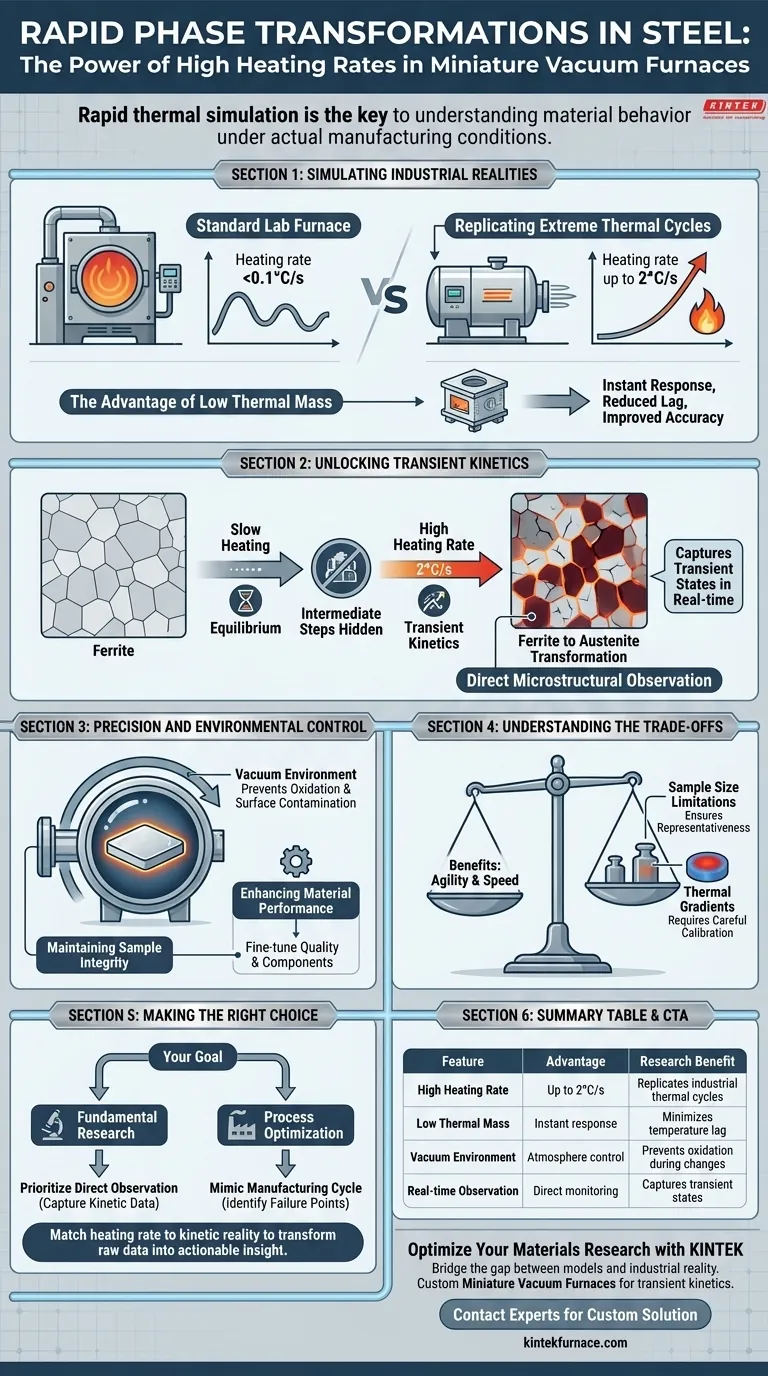

Rapid thermal simulation is the key to understanding how materials behave under actual manufacturing conditions. High heating rates, specifically those reaching up to 2°C per second in miniature vacuum furnaces, allow researchers to replicate the extreme thermal cycles inherent in industrial heat treatment. This capability is crucial for capturing transient kinetic processes, such as the transformation from ferrite to austenite in steel, which are often missed by slower, conventional heating methods.

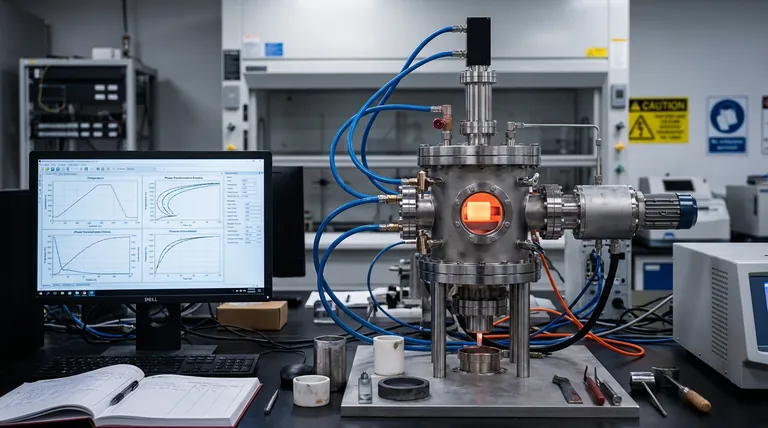

Miniature vacuum furnaces leverage low thermal mass to simulate extreme industrial thermal cycles. This precise control enables the direct observation of microstructural evolution, bridging the gap between theoretical models and real-world manufacturing conditions.

Simulating Industrial Realities

Replicating Extreme Thermal Cycles

Standard laboratory furnaces often heat too slowly to match the pace of industrial processing. Miniature vacuum furnaces solve this by achieving heating rates of up to 2°C per second. This allows researchers to subject test samples to the exact thermal stresses they would face on a production line.

The Advantage of Low Thermal Mass

The ability to heat rapidly is a direct result of the furnace's compact design. By utilizing low thermal mass components, the system minimizes the energy required to change temperature. This ensures that the furnace responds almost instantly to programming, reducing lag and improving simulation accuracy.

Unlocking Transient Kinetics

Capturing Phase Transformations

Many material changes, such as the ferrite to austenite transformation in steel, are highly sensitive to time and temperature. Slow heating allows the material to reach equilibrium, effectively "hiding" the intermediate steps of the transformation. High heating rates freeze these transient kinetic processes, allowing researchers to study exactly how the phase change occurs in real-time.

Direct Microstructural Observation

Understanding the end state of a material is not enough; you must understand the journey. These furnaces enable the direct observation of microstructural evolution as it happens. This insight helps identify at which precise moment and temperature critical changes in the material's crystal structure take place.

Precision and Environmental Control

Maintaining Sample Integrity

While speed is the primary benefit here, the vacuum environment plays a critical supporting role. As noted in broader materials processing contexts, vacuum furnaces offer precise control over atmosphere and cooling rates. This ensures that the rapid phase transformations are not obscured by oxidation or surface contamination.

Enhancing Material Performance

The ultimate goal of studying these rapid rates is to improve the final product. By controlling the thermal cycle, engineers can fine-tune the quality and performance of treated materials. This leads to components that meet the rigorous standards required for excellence in materials manufacturing.

Understanding the Trade-offs

Sample Size Limitations

The primary trade-off for such agility and speed is often scale. "Miniature" furnaces typically require small sample sizes to achieve these rapid rates uniformly. You must ensure that the small sample volume is truly representative of the bulk material you intend to study.

Thermal Gradients

Rapid heating induces a risk of thermal gradients within the sample itself. If the heating rate exceeds the material's thermal conductivity, the core temperature may lag behind the surface temperature. This requires careful calibration to ensure the data collected accurately reflects the internal state of the material.

Making the Right Choice for Your Goal

To maximize the value of high-rate vacuum furnaces, align your testing strategy with your specific objectives.

- If your primary focus is fundamental research: Prioritize the capability for direct observation to capture the kinetic data of phase transformations like ferrite to austenite.

- If your primary focus is process optimization: Use the high heating rates to mimic your specific manufacturing cycle to identify potential failure points or efficiency gains.

By matching the heating rate to the kinetic reality of your material, you transform raw data into actionable manufacturing insight.

Summary Table:

| Feature | Advantage | Research Benefit |

|---|---|---|

| High Heating Rate | Up to 2°C per second | Replicates industrial thermal cycles and kinetic stress |

| Low Thermal Mass | Instant thermal response | Minimizes temperature lag for accurate simulation |

| Vacuum Environment | Atmosphere control | Prevents oxidation during high-speed phase changes |

| Real-time Observation | Direct microstructural monitoring | Captures transient states like Ferrite-to-Austenite |

Optimize Your Materials Research with KINTEK

Bridge the gap between theoretical models and industrial reality. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all precision-engineered to meet the rigorous demands of material science. Our miniature vacuum furnaces are fully customizable, providing the low thermal mass and rapid heating rates essential for studying transient kinetics and microstructural evolution in steel and advanced alloys.

Ready to achieve superior thermal simulation accuracy?

Contact our experts today to find your custom solution

Visual Guide

References

- Jérôme Mendonça, Renaud Podor. Development of a microfurnace dedicated to <i>in situ</i> scanning electron microscope observation up to 1300 °C. III. <i>In situ</i> high temperature experiments. DOI: 10.1063/5.0207477

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are common heating elements used in vacuum furnaces? Optimize Your High-Temp Processes

- What temperature capabilities does the vacuum furnace system offer? Discover Precision Heating for Demanding Applications

- What is the role of inert gas in a vacuum furnace? Unlock Rapid, Controlled Cooling for Superior Metallurgy

- Why is repeated flipping and melting required in vacuum arc-melting? Ensure Homogeneity in Co-6Ti-11V-xNb Alloys

- Why is vacuum sublimation preferred over recrystallization for MTO? Achieve High-Purity Methyltrioxorhenium

- What is the purpose of using an industrial vacuum resistance furnace? Enhancing Ti-33Mo-0.2C Alloy Performance

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What are the key components of a vacuum furnace? Essential Systems for Precision Heat Treatment