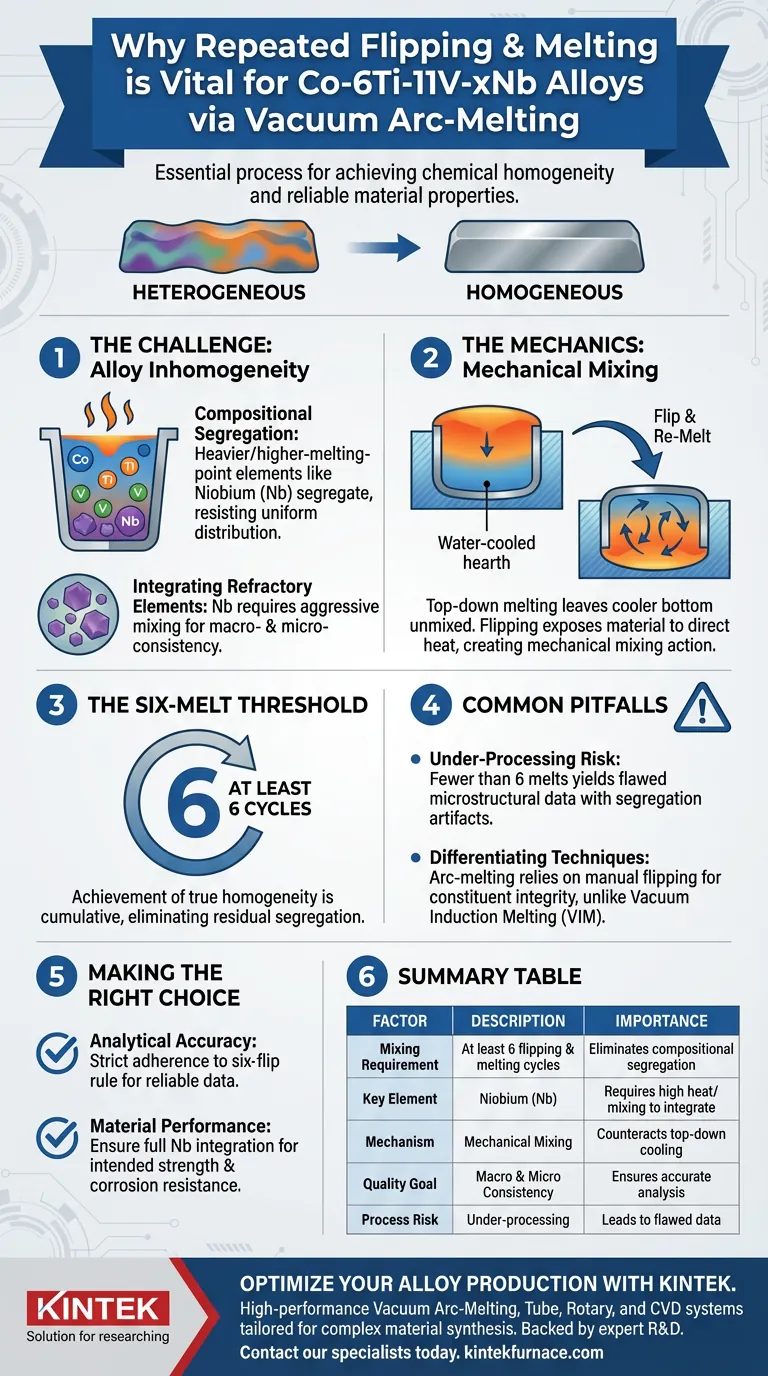

Repeated flipping and re-melting is essential to achieve chemical homogeneity in Co-6Ti-11V-xNb alloys produced via vacuum arc-melting. Because elements like Niobium (Nb) can segregate from the Cobalt matrix, the ingot must be mechanically mixed by flipping and melting it at least six times to ensure the composition is uniform at both macro and micro levels.

In vacuum arc-melting, a single pass is insufficient to fully integrate alloying elements. Repeatedly flipping and re-melting the sample acts as a mechanical mixing agent, eliminating compositional segregation and guaranteeing the material consistency required for accurate microstructural analysis.

The Challenge of Alloy Homogeneity

Combating Compositional Segregation

When melting complex alloys, elements do not always mix perfectly on the first attempt. Compositional segregation occurs when heavier or higher-melting-point elements fail to distribute evenly throughout the base metal.

In Co-6Ti-11V-xNb alloys, the distinct physical properties of the constituent elements create a natural resistance to uniformity. Without intervention, pockets of unmixed material can remain, compromising the integrity of the final ingot.

Integrating Refractory Elements

The inclusion of Niobium (Nb) presents a specific challenge in the Cobalt matrix. To ensure that Niobium reaches complete macro- and micro-level consistency, aggressive mixing is required.

If the Niobium is not fully integrated, the material properties will vary across the sample. This inconsistency renders subsequent testing unreliable, as the local chemistry will not reflect the intended overall composition.

The Mechanics of the Process

Mechanical Mixing via Re-melting

Vacuum arc-melting furnaces typically melt the sample from the top down in a water-cooled hearth. This can leave the bottom of the "button-shaped" sample cooler and less mixed than the top.

By flipping the sample, the operator exposes the previously bottom-facing material to the direct heat of the arc. This creates a mechanical mixing effect, forcing the constituents to interact and dissolve into one another repeatedly.

The Six-Melt Threshold

Achieving true homogeneity is not instantaneous; it is cumulative. Experience dictates that the sample must undergo this cycle at least six times.

Stopping short of this threshold increases the risk of residual segregation. The six-melt standard is the established baseline for ensuring the alloy is sufficiently uniform for scientific evaluation.

Common Pitfalls to Avoid

The Risk of Under-Processing

The most significant trade-off in this process is time versus accuracy. It may be tempting to reduce the number of melting cycles to save time, but this is a critical error.

If the alloy is melted fewer than six times, microstructural analysis will likely yield flawed data. The observations made under a microscope would represent local segregation artifacts rather than the true properties of the Co-6Ti-11V-xNb alloy.

Differentiating Melting Techniques

It is important to distinguish this specific mechanical mixing requirement from other smelting methods. While Vacuum Induction Melting (VIM) is excellent for removing impurities and general smelting, the arc-melting of button samples relies heavily on this manual flipping process to achieve the same level of constituent integrity.

Making the Right Choice for Your Goal

To ensure your alloy production meets the necessary standards for high-temperature applications or research, apply the following guidelines:

- If your primary focus is analytical accuracy: Strict adherence to the "six-flip" rule is mandatory to validate any subsequent microstructural data.

- If your primary focus is material performance: Ensure the Niobium is fully integrated to guarantee the alloy exhibits the intended strength and corrosion resistance.

Consistency in the furnace is the only path to reliability in the lab.

Summary Table:

| Factor | Description | Importance in Co-6Ti-11V-xNb |

|---|---|---|

| Mixing Requirement | At least 6 flipping & melting cycles | Eliminates compositional segregation and gradients |

| Key Element | Niobium (Nb) | Requires high heat/mixing to integrate into Cobalt matrix |

| Mechanism | Mechanical Mixing | Counteracts top-down cooling of water-cooled hearths |

| Quality Goal | Macro & Micro Consistency | Ensures microstructural analysis reflects true properties |

| Process Risk | Under-processing | Leads to flawed data and localized material failure |

Optimize Your Alloy Production with KINTEK

Achieving material consistency requires more than just technique—it requires precision equipment. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum Arc-Melting, Tube, Rotary, and CVD systems tailored for complex material synthesis. Whether you are working with refractory elements like Niobium or developing new high-temp alloys, our customizable lab furnaces provide the thermal control and reliability your research demands.

Ready to elevate your lab's performance? Contact our specialists today to find the perfect solution for your unique high-temperature processing needs.

Visual Guide

References

- The Effect of Nb on the Microstructure and High-Temperature Properties of Co-Ti-V Superalloys. DOI: 10.3390/coatings15010053

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- Why is a vacuum and atmosphere control system necessary for SiC sintering? Prevent Oxidation and Ensure High Purity

- What are the environmental advantages of vacuum furnaces? Reduce Emissions and Energy Use

- How does vacuum heating primarily transfer heat to the workpiece? Unlock Uniform Heat for Superior Results

- Why is a vacuum annealing furnace superior to air annealing for ZnSe/SiO2/Si? Protect Your Semiconductor Integrity

- What are the primary process functions of a vacuum oven in Fe3O4/C@PM synthesis? Ensure Material Integrity.

- How does dew point monitoring influence the process control of sintering furnaces in MIM? Ensure Peak Material Quality

- What industries benefit from vacuum heat treatment? Boost Performance in Aerospace, Automotive, and Medical

- How does a vacuum furnace contribute to the refining and degassing of alloy melts? Enhancing Metal Purity and Density