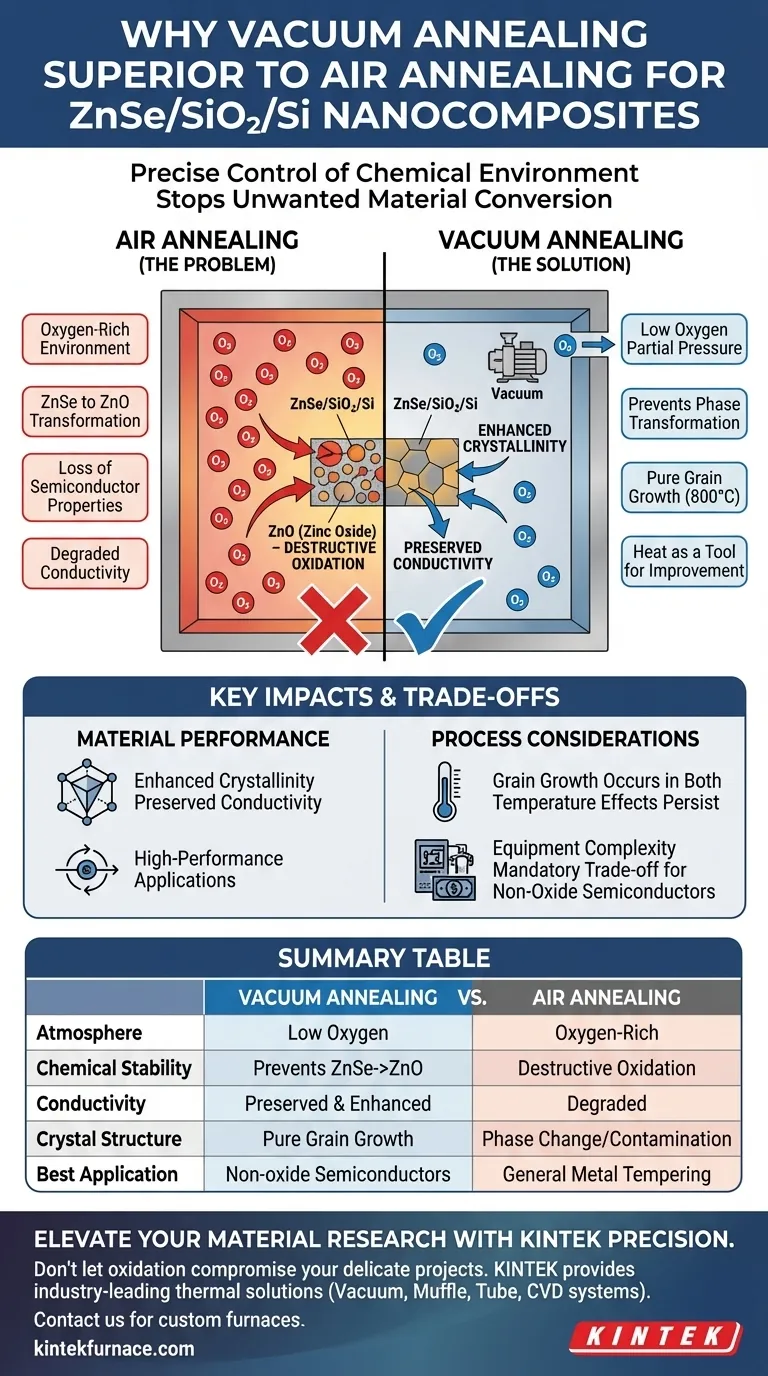

The primary advantage of using a vacuum annealing furnace is the precise control of the chemical environment. For ZnSe/SiO2/Si nanocomposites, specifically, the vacuum eliminates oxygen, preventing the unwanted chemical conversion of the material during high-temperature treatment.

While thermal treatment is necessary to improve the material's structure, doing so in air destroys the fundamental composition of Zinc Selenide. A vacuum environment allows for necessary structural enhancement without the destructive chemical side effects of oxidation.

The Critical Role of Atmosphere Control

Preventing Phase Transformation

The central issue with air annealing is the presence of oxygen. When Zinc Selenide (ZnSe) is exposed to high temperatures in an air atmosphere, it reacts chemically with oxygen.

This reaction causes a severe transformation of ZnSe into Zinc Oxide (ZnO). This phase change fundamentally alters the material, effectively removing the specific semiconductor properties you are trying to develop.

Reducing Oxygen Partial Pressure

A vacuum annealing furnace operates by significantly lowering the partial pressure of oxygen.

By removing oxygen from the chamber, the furnace creates a protected environment. This ensures that the thermal energy applied to the nanocomposite is used for structural refinement rather than fueling adverse chemical reactions.

Impact on Material Performance

Enhancing Crystallinity

High temperatures, such as 800°C, are required to promote grain growth and improve the crystal structure of the nanocomposite.

In a vacuum, this grain growth proceeds without interference. The result is a material with enhanced crystallinity, which is essential for high-performance applications.

Preserving Conductivity

The electrical properties of the nanocomposite rely on the integrity of the ZnSe phase.

Because vacuum annealing inhibits the formation of insulating or chemically distinct oxide layers (ZnO), it helps preserve and enhance conductivity. It maintains the intrinsic semiconductor characteristics that would otherwise be lost in an air-annealed sample.

Understanding the Trade-offs

Temperature Effects Persist

It is important to note that a vacuum does not stop all physical changes. As indicated by the behavior at 800°C, grain growth occurs regardless of the atmosphere.

While vacuum prevents chemical degradation, it does not prevent the physical coarsening of grains. If limiting grain size is critical for your application, temperature and time must be controlled independently of the atmosphere.

Equipment Complexity

Vacuum furnaces are significantly more complex and expensive to operate than standard air furnaces.

However, for non-oxide semiconductors like ZnSe, this complexity is a mandatory trade-off. The cost of the equipment is justified by the fact that air annealing yields a chemically different, and likely unusable, end product.

Making the Right Choice for Your Goal

When selecting a thermal treatment method for sensitive nanocomposites, consider your specific material requirements:

- If your primary focus is Compositional Purity: You must use vacuum annealing to prevent the oxidation of ZnSe into ZnO and retain the intended semiconductor phase.

- If your primary focus is Electrical Performance: Vacuum treatment is required to enhance conductivity by ensuring the crystal lattice is refined without introducing oxide impurities.

By removing oxygen from the equation, vacuum annealing ensures that heat acts as a tool for improvement rather than an agent of degradation.

Summary Table:

| Feature | Vacuum Annealing | Air Annealing |

|---|---|---|

| Atmosphere | Low oxygen partial pressure | Oxygen-rich environment |

| Chemical Stability | Prevents ZnSe to ZnO transformation | Leads to destructive oxidation |

| Conductivity | Preserved and enhanced | Degraded by oxide formation |

| Crystal Structure | Pure grain growth | Phase change/contamination |

| Best Application | Non-oxide semiconductors | General metal tempering |

Elevate Your Material Research with KINTEK Precision

Don’t let oxidation compromise your delicate semiconductor projects. KINTEK provides industry-leading thermal solutions designed for the rigorous demands of nanocomposite development. Backed by expert R&D and manufacturing, we offer high-performance Vacuum, Muffle, Tube, and CVD systems—all fully customizable to your specific partial pressure and temperature requirements.

Take control of your chemical environment today. Contact us now to discuss your custom furnace needs and ensure your materials achieve their maximum potential with KINTEK expertise.

Visual Guide

References

- Aiman Akylbekovа, Anatoli I. Popov. Annealing Effect on Structural, Optical and Electrophysical Properties of ZnSe Nanocrystals Synthesized into SiO2/Si Ion Track Template. DOI: 10.3390/ma17164149

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity