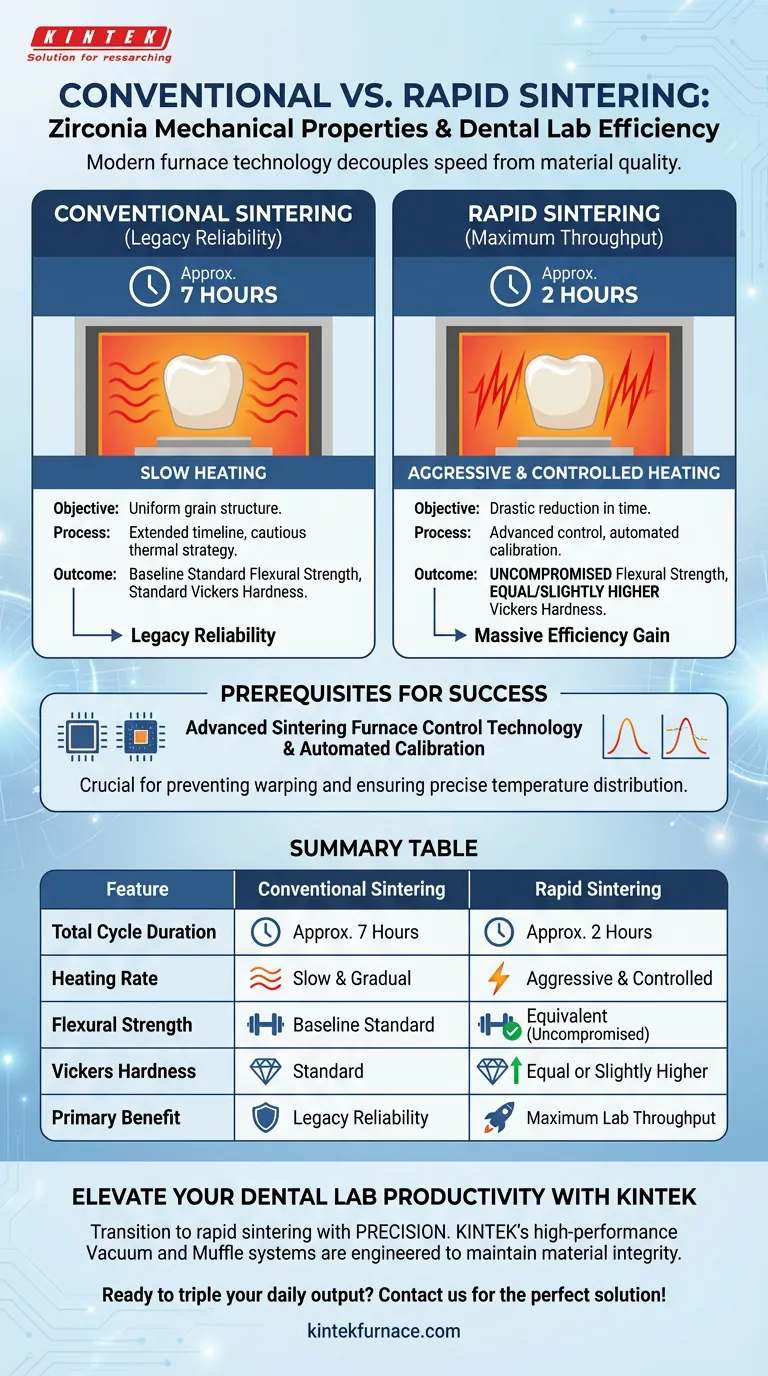

Rapid sintering cycles can significantly increase processing efficiency without sacrificing mechanical integrity. While conventional sintering relies on slow heating over approximately 7 hours to ensure grain uniformity, research indicates that rapid cycles (around 2 hours) utilizing advanced furnace controls can match or even exceed the Vickers hardness of zirconia while maintaining equivalent flexural strength.

Modern dental furnace technology has effectively decoupled processing speed from material quality. With precise thermal control, laboratories can reduce sintering times by nearly 70% while achieving mechanical properties that are equal to, or better than, those produced by traditional slow-heating methods.

The Mechanics of Conventional Sintering

The Objective of Slow Heating

Conventional sintering is designed around a cautious thermal strategy. The primary goal is to produce a uniform grain structure throughout the restoration.

Typical Duration and Process

To achieve this structural homogeneity, conventional cycles typically last approximately 7 hours. This extended timeline accommodates a slow heating rate, which has traditionally been viewed as necessary to manage the material properties of zirconia and prevent thermal shock.

Mechanical Outcomes

The long hold times and slow ramp rates result in reliable, standard mechanical properties. This method serves as the baseline for flexural strength and hardness in dental zirconia restorations.

The Impact of Rapid Sintering

Drastic Reduction in Time

Rapid sintering cycles fundamentally alter the workflow by raising the heating rate and significantly shortening the holding time. This reduces the total process duration to approximately 2 hours, offering a massive gain in laboratory efficiency.

Impact on Hardness

Contrary to the assumption that speed reduces quality, rapid sintering does not degrade the surface density. Studies show that these cycles can match or even exceed the Vickers hardness of milled zirconia processed via conventional methods.

Retention of Flexural Strength

Crucially, the increase in speed does not induce brittleness or structural weakness. The flexural strength of the zirconia remains uncompromised, meaning the restoration retains its ability to resist fracture under load just as well as conventionally sintered counterparts.

Understanding the Prerequisites

The Necessity of Advanced Control

You cannot simply accelerate a standard cycle and expect optimal results. Successful rapid sintering relies heavily on advanced sintering furnace control technology.

Automation and Calibration

Modern furnaces utilize sophisticated software and automated calibration to manage the aggressive heating rates. These features ensure the temperature distribution remains precise, preventing the warping or uneven shrinkage that would otherwise occur with uncontrolled rapid heating.

Making the Right Choice for Your Workflow

The decision between conventional and rapid sintering often depends on your equipment capabilities and volume requirements.

- If your primary focus is maximum throughput: Adopt rapid sintering cycles (approx. 2 hours), provided your furnace supports advanced thermal control, to maintain high hardness and strength while tripling daily output.

- If your primary focus is strictly adhering to legacy protocols: Continue using conventional 7-hour cycles if your equipment lacks the advanced calibration features necessary for safe rapid heating.

By leveraging modern furnace technology, you can achieve the speed required for high-volume production without compromising the durability or fit of the final restoration.

Summary Table:

| Feature | Conventional Sintering | Rapid Sintering |

|---|---|---|

| Total Cycle Duration | Approx. 7 Hours | Approx. 2 Hours |

| Heating Rate | Slow & Gradual | Aggressive & Controlled |

| Flexural Strength | Baseline Standard | Equivalent (Uncompromised) |

| Vickers Hardness | Standard | Equal or Slightly Higher |

| Primary Benefit | Legacy Reliability | Maximum Lab Throughput |

Elevate Your Dental Lab Productivity with KINTEK

Transitioning to rapid sintering cycles requires more than just speed—it demands the precision of KINTEK’s high-performance dental furnace technology. Backed by expert R&D and manufacturing, we provide customizable Vacuum and Muffle systems engineered specifically to maintain material integrity during accelerated thermal cycles. Our furnaces ensure your zirconia restorations achieve peak hardness and strength with every batch.

Ready to triple your daily output? Contact us today to find the perfect sintering solution for your lab!

Visual Guide

References

- Maher S. Hajjaj, Hanin E. Yeslam. Flexural strength, flexural modulus and microhardness of milled vs. fused deposition modeling printed Zirconia; effect of conventional vs. speed sintering. DOI: 10.1186/s12903-023-03829-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the main advantages of a dental sintering furnace? Boost Quality, Efficiency, and Profits

- What maintenance is required for a dental ceramic furnace? Ensure Precision and Longevity for Your Lab

- What is a zirconia sintering furnace? Unlock High-Strength, Aesthetic Dental Ceramics

- What are the key features of a high-quality sintering furnace? Ensure Precision, Uniformity, and Reliability

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- How does a lack of user training impact a dental furnace? Avoid Costly Errors and Ensure Quality

- What connectivity options might a dental sintering furnace offer? Boost Your Lab's Digital Workflow

- Why is it important not to ignore the preheat and cooldown phases when using a dental furnace? Prevent Cracks & Ensure Restoration Success