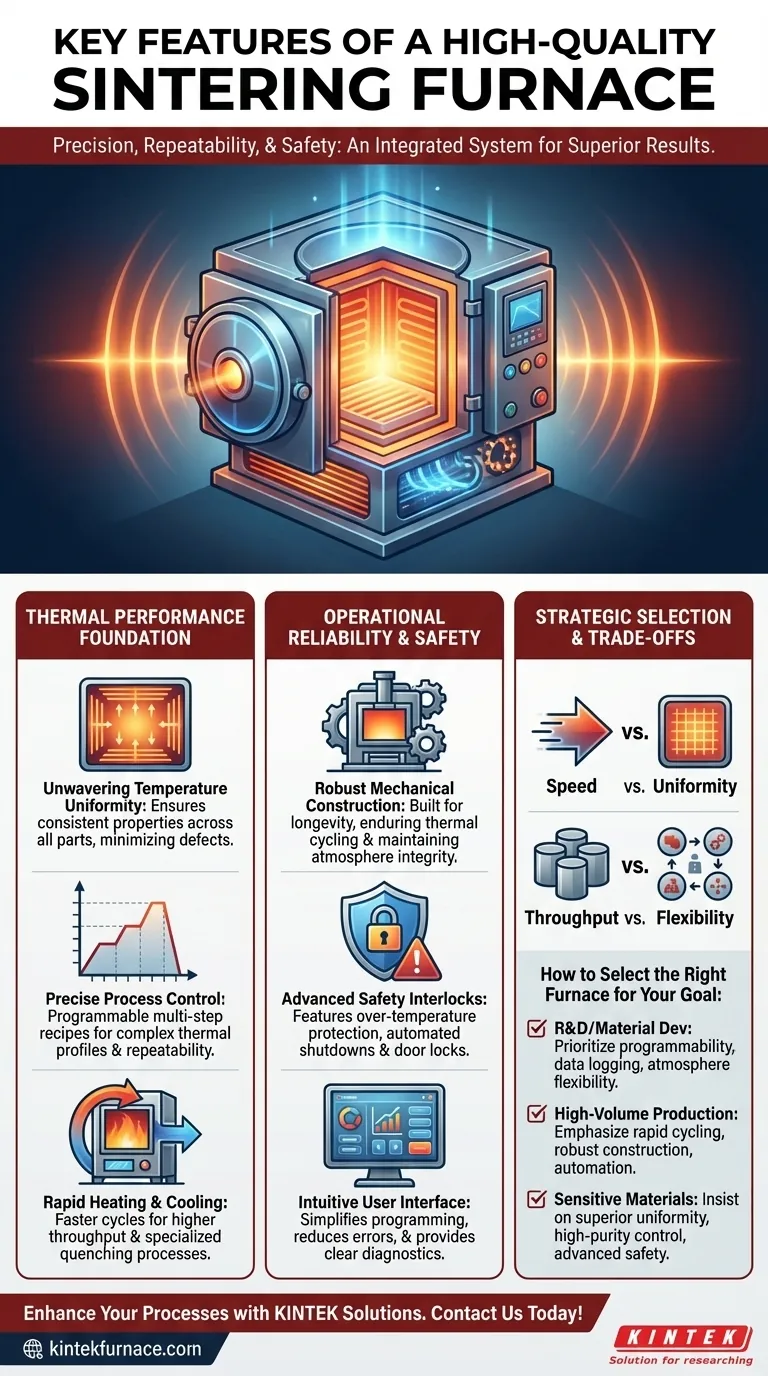

When evaluating a sintering furnace, the defining characteristics extend beyond mere heating capability. A high-quality furnace is an integrated system designed for precision, repeatability, and safety, distinguished by its precise temperature control, flexible process programming, rapid thermal cycling, and robust physical construction. These features work in concert to ensure consistent, reliable material processing.

The core measure of a sintering furnace is not simply its maximum temperature, but its ability to execute a thermal profile with absolute precision and repeatability. The best furnaces merge superior thermal performance with robust engineering and intuitive control to guarantee quality outcomes, cycle after cycle.

The Foundation: Thermal Performance

The primary function of any furnace is to deliver heat. However, a high-quality sintering furnace is defined by how precisely and uniformly it manages that thermal energy.

Unwavering Temperature Uniformity

This is the most critical feature. Temperature uniformity ensures that all parts within the chamber, regardless of their position, experience the exact same thermal conditions.

Poor uniformity leads to inconsistent densification, warping, and varied material properties across a single batch, compromising quality and yield. Designs that incorporate features like a strongly cooled furnace body help isolate the hot zone, minimizing thermal gradients and improving uniformity.

Precise Process Control

Modern material science requires complex thermal profiles. A superior furnace offers multiple programmable settings, allowing operators to design multi-step "recipes" with specific ramp rates, hold times (soaks), and cooling profiles.

This level of control is essential for developing new materials and ensuring that production processes are perfectly repeatable, eliminating process drift.

Rapid Heating and Cooling

The ability to heat and cool quickly, often called rapid cycling, directly impacts productivity. Faster cycles mean higher throughput.

For certain materials, rapid cooling (quenching) is also a critical process step used to lock in specific desirable microstructures, enhancing the material's final properties.

Operational Reliability and Safety

A furnace must be a reliable and safe tool. Its design and construction are just as important as its thermal performance.

Robust Mechanical Construction

A high-quality furnace is built for longevity and continuous operation. Robust construction means using high-grade materials, strong welds, and a design that withstands repeated thermal cycling without warping or degradation.

This structural integrity is also vital for maintaining atmosphere purity or vacuum levels, which are critical for processing sensitive materials.

Advanced Safety Interlocks

Safety is non-negotiable. Modern furnaces incorporate a suite of advanced safety features to protect both the operator and the equipment.

These include over-temperature protection, automated shutdowns in case of cooling water or gas flow failure, and door interlocks that prevent opening under unsafe conditions.

Intuitive User Interface

The most advanced features are useless if they are difficult to use. A user-friendly interface simplifies programming complex cycles, reduces the chance of operator error, and provides clear diagnostic information.

This ensures that the furnace's capabilities are accessible and can be used to their full potential consistently.

Understanding the Trade-offs

Selecting a furnace involves balancing competing priorities. Understanding these trade-offs is key to making an informed decision.

Speed vs. Uniformity

Achieving extremely rapid heating rates can sometimes compromise temperature uniformity, especially in larger furnace chambers. The design of the heating elements and insulation is critical to balancing these two factors.

Cost vs. Capability

Advanced features like high-vacuum systems, specialized gas handling, or forced rapid cooling add significant cost and complexity. You must justify these features based on a clear process requirement rather than a "nice-to-have" desire.

Throughput vs. Flexibility

Large-batch production furnaces are optimized for throughput but may be less flexible for research and development. Smaller lab-scale furnaces offer greater flexibility for process experimentation but at the cost of lower volume.

How to Select the Right Furnace for Your Goal

Your specific application should dictate which features you prioritize.

- If your primary focus is R&D and material development: Prioritize precise programmability, data logging capabilities, and the flexibility to handle different atmospheres and thermal profiles.

- If your primary focus is high-volume production: Emphasize rapid cycling for throughput, robust construction for minimal downtime, and automation features for repeatability.

- If your primary focus is processing highly sensitive materials: Insist on superior temperature uniformity, high-purity atmosphere or vacuum control, and advanced safety interlocks.

Ultimately, a well-chosen furnace is a long-term investment in process control, consistency, and quality.

Summary Table:

| Feature | Description |

|---|---|

| Temperature Uniformity | Ensures consistent heating across the chamber for uniform material densification and quality. |

| Precise Process Control | Allows programmable multi-step recipes with specific ramp rates, hold times, and cooling profiles. |

| Rapid Heating and Cooling | Increases throughput and enables quenching for specific microstructures. |

| Robust Construction | Uses high-grade materials for longevity, thermal cycling resistance, and atmosphere integrity. |

| Advanced Safety Interlocks | Includes over-temperature protection, automated shutdowns, and door interlocks for operator safety. |

| Intuitive User Interface | Simplifies programming, reduces errors, and provides clear diagnostics for ease of use. |

Ready to enhance your sintering processes with precision and reliability? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by strong deep customization capabilities to meet your unique experimental and production requirements. Whether you're in R&D, high-volume production, or handling sensitive materials, we deliver consistent performance and safety. Contact us today to discuss how our sintering furnaces can optimize your lab's efficiency and results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents