In simple terms, a zirconia sintering furnace is a high-temperature, precision-controlled oven used to transform a soft, chalk-like zirconia material into a dense, strong, and aesthetically pleasing ceramic. This process, known as sintering, is the critical final step in fabricating durable dental restorations like crowns and bridges, as well as high-end jewelry.

A sintering furnace is not just a heat source; it is a specialized instrument that executes a precise thermal program. Its purpose is to densify the zirconia without melting it, systematically shrinking the material to achieve its final strength and translucency.

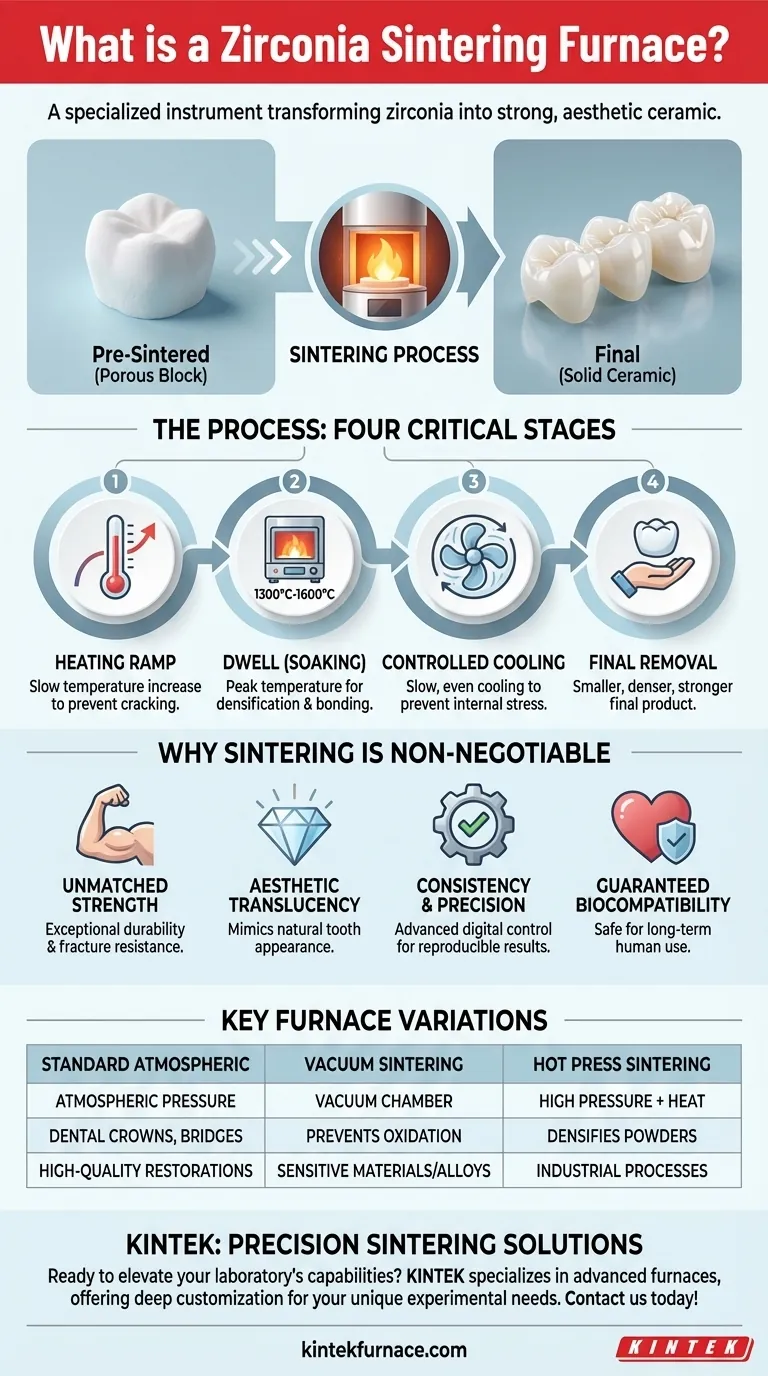

The Process: From Porous Block to Solid Ceramic

The function of a zirconia sintering furnace is best understood as a controlled transformation. It takes a pre-shaped, porous zirconia blank and turns it into a final, fully dense product through a carefully managed heating and cooling cycle.

The Core Principle: Sintering

Sintering is a process where heat is applied to a powdered material, causing its particles to bond together and form a solid, dense mass.

This happens at a temperature below the material's melting point. Instead of liquefying, the atoms migrate across the boundaries of the particles, fusing them together and eliminating the pores between them.

The Four Critical Stages

A typical sintering cycle is a meticulously programmed sequence designed to ensure a perfect outcome without causing thermal shock or stress fractures.

- Heating Ramp: The furnace slowly and gradually raises the temperature. This controlled ramp-up prevents the zirconia from cracking due to rapid thermal expansion.

- Dwell (or Soaking): The furnace reaches and holds a peak temperature, typically between 1300°C and 1600°C. This is where the majority of densification and particle bonding occurs. The duration of this stage is critical for achieving the desired properties.

- Controlled Cooling: Just as important as heating, the furnace cools down slowly and evenly. A controlled cool-down prevents internal stresses and the formation of cracks, ensuring the structural integrity of the final piece.

- Final Removal: Once cooled, the fully sintered zirconia part is removed. It is now significantly smaller, denser, and stronger than the pre-sintered blank it started as.

Why Sintering is Non-Negotiable for Zirconia

Using a specialized furnace isn't optional; it's the only way to unlock the material properties that make zirconia so valuable in medical and aesthetic applications.

Achieving Unmatched Strength

The sintering process is directly responsible for zirconia's exceptional durability and fracture resistance. The densification eliminates weak points, creating a monolithic structure capable of withstanding significant mechanical forces, such as chewing.

Gaining Aesthetic Translucency

In its pre-sintered state, zirconia is opaque and chalky. The sintering process alters its crystalline structure, creating the desired level of translucency that allows it to mimic the appearance of a natural tooth.

Ensuring Consistency and Precision

Modern sintering furnaces offer advanced digital control over the entire thermal cycle. This ensures that every part undergoes the exact same process, resulting in highly consistent and reproducible outcomes, which is essential for any dental laboratory or manufacturing facility.

Guaranteeing Biocompatibility

The high-temperature process creates a pure, inert ceramic. This makes the final zirconia product highly biocompatible and safe for long-term use inside the human body without causing adverse reactions.

Understanding Key Furnace Variations

While the core principle remains the same, different types of furnaces exist for specialized applications. Understanding these distinctions is key to selecting the right tool for the job.

Standard Atmospheric Furnaces

This is the most common type used for dental zirconia. It operates at normal atmospheric pressure and is perfectly suited for producing high-quality crowns, bridges, and other restorations.

Vacuum Sintering Furnaces

These furnaces create a vacuum inside the heating chamber before raising the temperature. Removing atmospheric gases like oxygen prevents oxidation and contamination of the material. This is critical when sintering sensitive materials or high-purity refractory alloys, such as tungsten and molybdenum.

Hot Press Sintering Furnaces

This specialized equipment applies high pressure simultaneously with high temperature in a vacuum environment. The external pressure actively aids in the densification of ceramic powders that may be difficult to sinter using heat alone. This is a more industrial process not typically used for standard dental zirconia restorations.

Making the Right Choice for Your Goal

Selecting the correct process depends entirely on the material you are working with and the properties you need to achieve in the final product.

- If your primary focus is standard dental restorations: A conventional zirconia sintering furnace provides the precise thermal control needed for exceptional strength and aesthetics.

- If your primary focus is high-purity metals or specialty alloys: A vacuum sintering furnace is essential to prevent oxidation and ensure the integrity of the final material.

- If your primary focus is densifying unique ceramic powders: A hot press sintering furnace may be required to achieve fusion and density under combined heat and pressure.

Ultimately, mastering the sintering cycle is the key to unlocking the full performance potential of advanced ceramic materials.

Summary Table:

| Feature | Description |

|---|---|

| Process | Sintering at high temperatures (1300°C-1600°C) to densify zirconia without melting |

| Key Stages | Heating ramp, dwell, controlled cooling, final removal |

| Benefits | Enhanced strength, aesthetic translucency, consistency, and biocompatibility |

| Furnace Types | Standard atmospheric, vacuum (prevents oxidation), hot press (for specialized ceramics) |

| Applications | Dental crowns/bridges, jewelry, high-purity metals, and specialty alloys |

Ready to elevate your laboratory's capabilities with precision sintering solutions? KINTEK specializes in advanced high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—whether for dental ceramics, jewelry, or industrial materials. Contact us today to discuss how our tailored furnace solutions can enhance your product quality and efficiency!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity