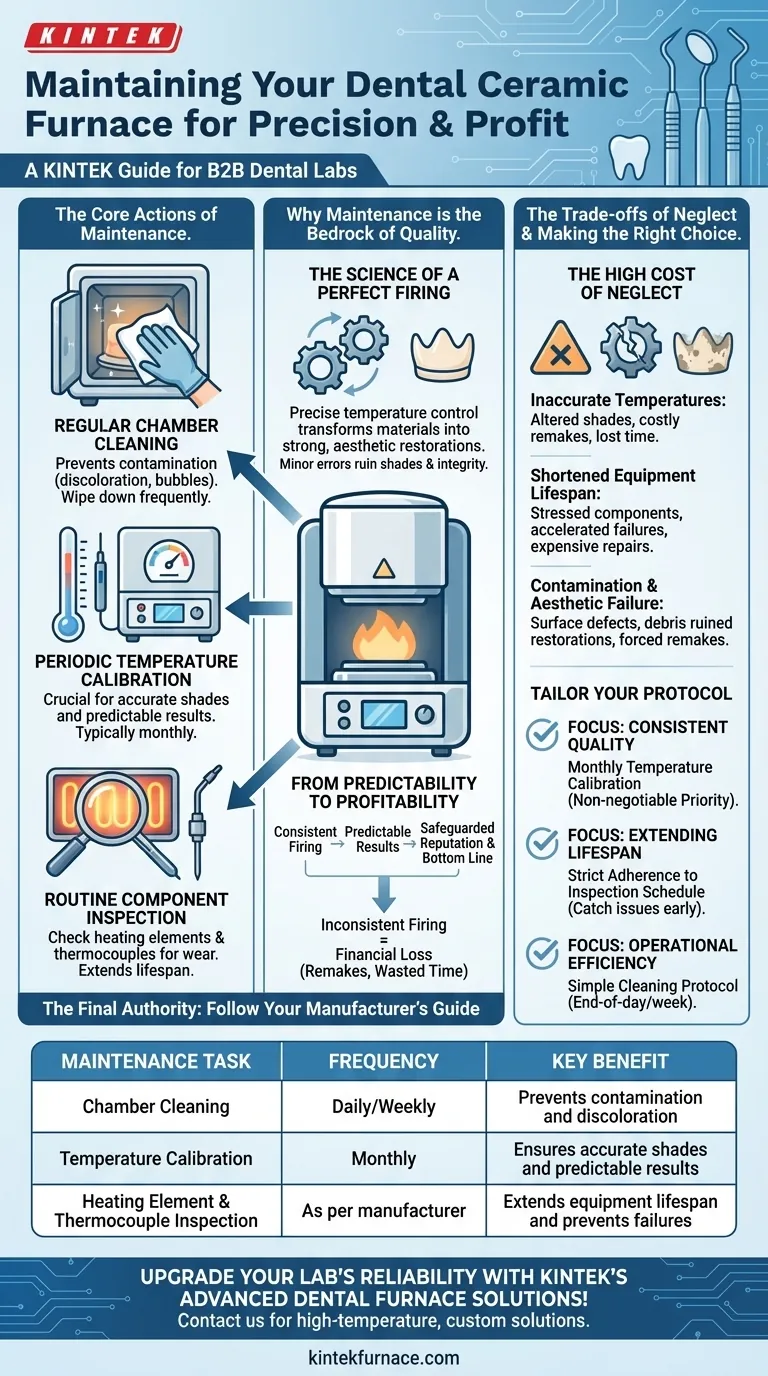

At its core, maintaining a dental ceramic furnace involves three critical actions. These are the regular cleaning of the firing chamber, the periodic calibration of its temperature controls, and the routine inspection of key wear components like heating elements and thermocouples. Following the manufacturer's specific guidelines is the final, essential piece of this process.

Your ceramic furnace is not just a heater; it is a precision instrument directly responsible for the quality and profitability of your lab. Consistent maintenance is not about preventing a breakdown—it's about guaranteeing the accuracy and predictability of every firing cycle, which is the foundation of high-quality dental restorations.

Why Maintenance is the Bedrock of Quality Restorations

A dental furnace's sole purpose is to execute a firing program with absolute precision. Any deviation compromises the final product, turning a potential masterpiece into a costly remake.

The Science of a Perfect Firing

The furnace transforms ceramic materials into strong, aesthetic restorations like crowns and veneers through carefully controlled heating. This process relies on hitting exact temperatures at specific times to achieve proper crystallization and bonding.

Even a minor temperature error can ruin the shade, translucency, and structural integrity of the ceramic.

From Predictability to Profitability

Inconsistent firing cycles lead directly to financial loss. A poor fit, an incorrect shade, or a weak restoration means wasted materials, lost technician time, and a delayed case delivery.

Disciplined maintenance ensures every firing cycle is predictable and repeatable, safeguarding your lab's reputation and bottom line.

A Practical Maintenance Checklist

Think of furnace maintenance not as a chore, but as a system of quality control. Integrating these steps into your lab's workflow is essential.

Routine Task: Chamber Cleaning

Debris or contaminants left inside the firing chamber can vaporize during a cycle. These contaminants can then embed themselves into the porcelain, causing discoloration or bubbles.

Wipe down the firing chamber regularly according to the manufacturer's instructions to ensure a pure firing environment for every restoration.

Critical Task: Temperature Calibration

Over time, all furnaces experience "temperature drift." The displayed temperature may no longer match the actual temperature inside the chamber.

Calibrating the furnace—typically on a monthly basis—is the single most important maintenance task. It ensures the temperatures in your firing programs are the temperatures being delivered to the restoration. This is non-negotiable for achieving accurate shades.

Periodic Inspection: Heating Elements & Thermocouple

The heating element creates the heat, and the thermocouple measures it. Both are wear-and-tear parts.

A degrading heating element may cause the furnace to heat up too slowly or unevenly. A failing thermocouple will send inaccurate temperature data to the controller, making your calibration and programming efforts useless. Regular inspection allows you to replace these parts before they cause a catastrophic failure.

The Final Authority: Your Manufacturer's Guide

Every furnace model has unique requirements. Your user manual provides the definitive schedule and procedure for cleaning, calibration, and component replacement. Adhering to it is critical for both performance and warranty compliance.

Understanding the Trade-offs of Neglect

Skipping maintenance might save a few minutes today, but it introduces significant risk and cost over the long term.

The High Cost of Inaccurate Temperatures

A furnace that is off by even a few degrees can completely alter the final shade of a ceramic. This is especially damaging on multi-unit cases where aesthetic consistency is paramount. A single failed firing can cost hundreds or thousands of dollars in lost materials and labor.

Shortened Equipment Lifespan

Allowing components to operate past their service life puts stress on the entire system. A weak heating element forces the power supply to work harder, accelerating its failure. Proactive replacement is always cheaper than reactive repair.

Contamination and Aesthetic Failure

A dirty firing chamber is a primary cause of surface defects and discoloration. What appears to be a small amount of debris can ruin an otherwise perfect restoration, forcing a complete remake.

Making the Right Choice for Your Goal

To integrate this into your workflow, tailor your maintenance protocol to your lab's specific priorities.

- If your primary focus is consistent quality and aesthetics: Make temperature calibration your number one, non-negotiable monthly priority.

- If your primary focus is extending equipment lifespan and ROI: Adhere strictly to the manufacturer's inspection schedule for heating elements and thermocouples to catch issues early.

- If your primary focus is day-to-day operational efficiency: Implement a simple end-of-day or end-of-week cleaning protocol for the firing chamber to prevent contamination buildup.

A disciplined maintenance routine transforms your furnace from a potential liability into your most reliable production asset.

Summary Table:

| Maintenance Task | Frequency | Key Benefit |

|---|---|---|

| Chamber Cleaning | Daily/Weekly | Prevents contamination and discoloration |

| Temperature Calibration | Monthly | Ensures accurate shades and predictable results |

| Heating Element & Thermocouple Inspection | As per manufacturer | Extends equipment lifespan and prevents failures |

Upgrade your lab's reliability with KINTEK's advanced dental furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer high-temperature furnaces like Muffle, Tube, and Vacuum & Atmosphere Furnaces, tailored to your unique needs. Our deep customization ensures precise performance for consistent, high-quality dental restorations. Contact us today to discuss how we can enhance your lab's efficiency and profitability!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures