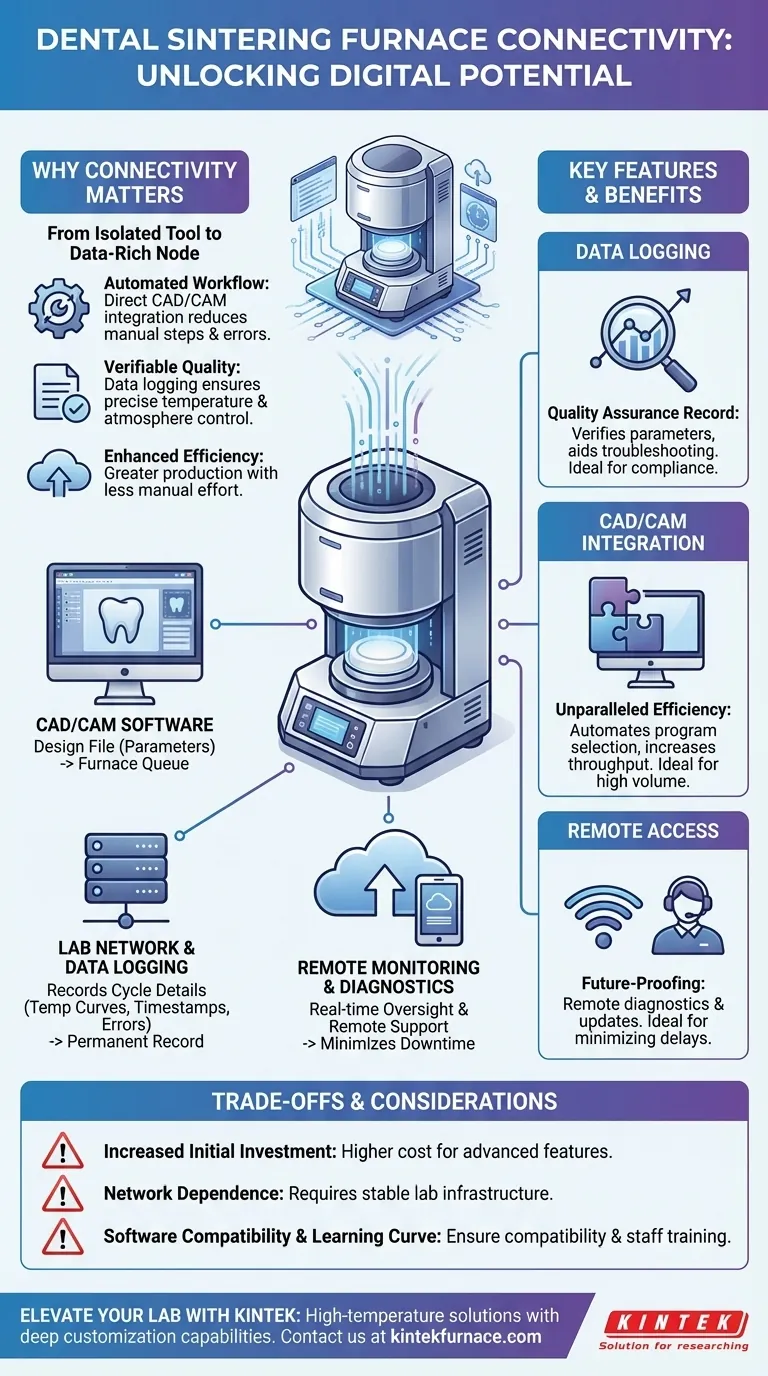

In short, modern dental sintering furnaces primarily offer connectivity for data logging and direct integration with CAD/CAM systems. These features are designed to move the furnace from a standalone piece of equipment to an intelligent, integrated part of a digital dental workflow, significantly enhancing both quality control and operational efficiency.

Connectivity transforms a furnace from an isolated tool into a data-rich node in your digital workflow. This shift is less about the technology itself and more about achieving verifiable quality and greater production efficiency with less manual effort.

Why Connectivity Matters in Modern Dentistry

The role of a sintering furnace is evolving. Once a simple "oven," it is now a critical control point in the production of high-quality dental restorations. Connectivity is the key to unlocking its full potential within a digital lab environment.

From Manual Steps to Automated Workflow

Traditionally, a technician would manually select and start a sintering program based on the material being used. This introduced opportunities for human error, potentially leading to costly remakes.

Integrated furnaces streamline this process. By connecting to the lab's network and CAD/CAM software, the furnace can receive the correct firing parameters directly from the design file, ensuring the right cycle is run for the right material, every time.

Ensuring Quality Through Verifiable Data

A core function of a sintering furnace is maintaining precise temperature and atmosphere control to ensure uniform quality. Without data logging, you can only assume a cycle ran correctly.

Connectivity provides proof. By logging every detail of the sintering cycle, you create a permanent record that can be used for quality assurance, troubleshooting, and validating results for dentists and patients.

Breaking Down the Key Connectivity Features

While features vary by manufacturer, two primary types of connectivity provide the most significant benefits for a dental laboratory.

Data Logging: Your Quality Assurance Record

Data logging is the furnace's ability to record and export critical parameters from each sintering cycle. This often includes temperature curves, cycle duration, timestamps, and any error codes that occurred.

This raw data is invaluable. It allows you to verify that each batch was processed according to the material manufacturer's specifications, providing traceability and a powerful diagnostic tool if restorations fail.

CAD/CAM Integration: For Unparalleled Efficiency

This is the most impactful feature for workflow automation. Direct integration allows your CAD/CAM software to communicate with the furnace.

When a restoration is designed and nested for milling, the associated sintering program is linked to the job. Once milled, the technician simply scans the case, and the furnace automatically queues the correct, pre-validated program, drastically reducing labor costs and eliminating programming errors.

Remote Monitoring and Diagnostics

Some advanced furnaces offer network or cloud connectivity for remote access. This allows lab managers to monitor cycle progress from a computer or mobile device.

It also enables manufacturers' support teams to remotely diagnose issues, review cycle logs, and push software updates, minimizing downtime and streamlining maintenance.

Understanding the Trade-offs

While connectivity offers powerful advantages, it's important to approach it with a clear understanding of the associated considerations. A connected furnace is a more complex piece of equipment.

Increased Initial Investment

Furnaces with advanced integration and data logging capabilities typically carry a higher price tag. This cost must be weighed against the long-term benefits of reduced labor, fewer remakes, and improved quality control.

Dependence on Network Infrastructure

To realize the benefits of integration, you need a stable and reliable lab network. Network outages or configuration issues can disrupt the automated workflow, forcing a temporary return to manual operation.

Software Compatibility and Learning Curve

Integration is not always "plug and play." You must ensure the furnace's software is compatible with your specific CAD/CAM ecosystem. Staff will also require training to move from a manual process to a new, integrated workflow.

Making the Right Choice for Your Lab

The right level of connectivity depends entirely on your lab's specific goals and production volume.

- If your primary focus is quality assurance and traceability: Prioritize a furnace with robust, easily exportable data logging capabilities.

- If your primary focus is high-volume production and efficiency: Deep integration with your existing CAD/CAM software is the most critical feature to pursue.

- If your primary focus is future-proofing and minimizing downtime: Look for models that offer remote monitoring and diagnostic support.

Choosing a furnace is a strategic investment in your lab's quality and efficiency.

Summary Table:

| Feature | Key Benefits | Ideal For |

|---|---|---|

| Data Logging | Verifies cycle parameters, ensures traceability, aids troubleshooting | Labs focused on quality assurance and regulatory compliance |

| CAD/CAM Integration | Automates program selection, reduces errors, increases throughput | High-volume production labs seeking workflow efficiency |

| Remote Monitoring | Allows real-time oversight, enables remote diagnostics, minimizes downtime | Labs prioritizing future-proofing and reduced maintenance delays |

Ready to elevate your dental lab with advanced sintering solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide high-temperature furnaces tailored for dental laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental needs. Contact us today to discuss how our connected furnace options can enhance your quality control and operational efficiency!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Spark Plasma Sintering SPS Furnace

People Also Ask

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations