The primary advantages of a dental sintering furnace are its ability to deliver superior restoration quality through precise process control, dramatically increase a lab's efficiency, and provide significant economic benefits. By integrating this technology, dental professionals gain direct control over the production of strong, perfectly-fitting ceramic restorations while reducing both turnaround times and operational costs.

A dental sintering furnace is not just a piece of equipment; it is a strategic investment that transforms a dental lab or clinic's capabilities. It enables the in-house production of highly durable and accurate ceramic restorations, fundamentally improving quality control, speed, and profitability.

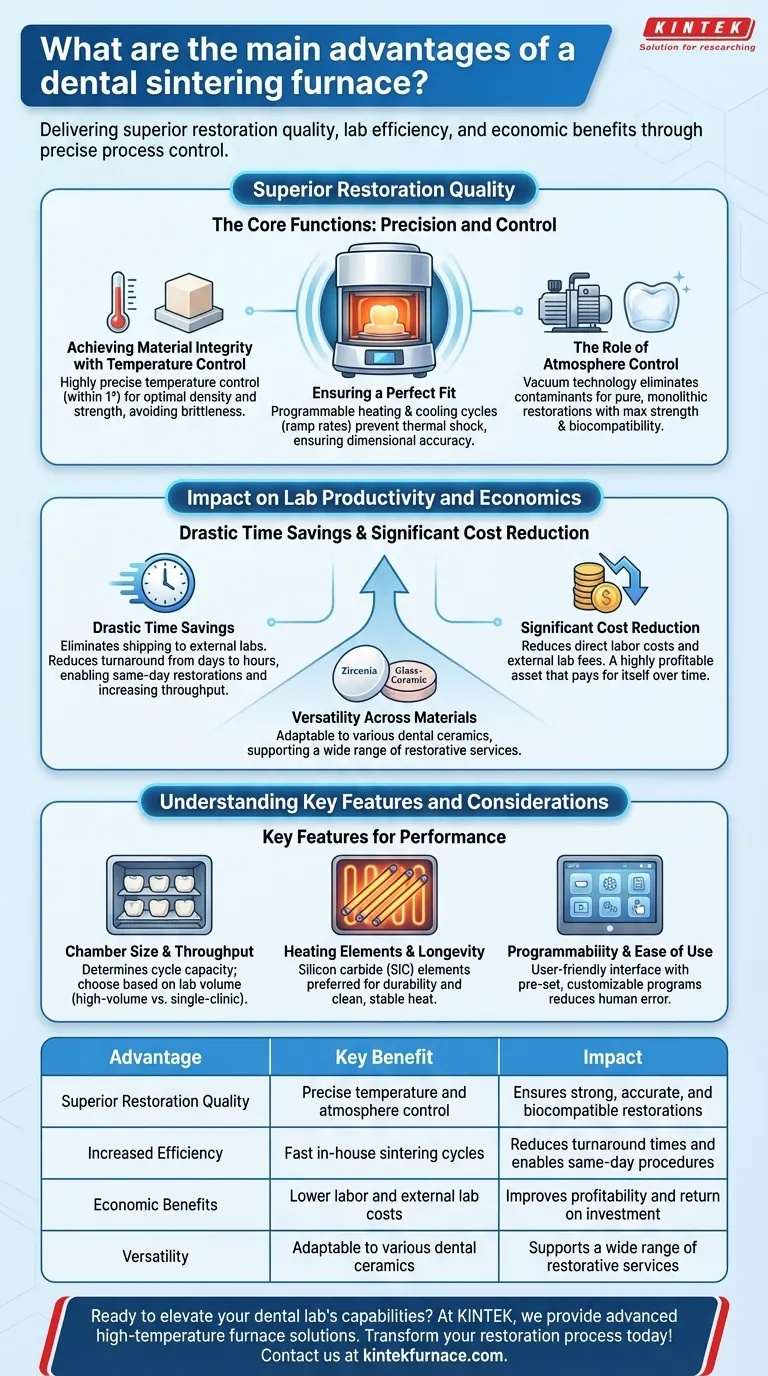

The Core Functions: Precision and Control

The ultimate goal of any dental restoration is a perfect, long-lasting fit. A sintering furnace achieves this through an unparalleled level of control over the material transformation process.

Achieving Material Integrity with Temperature Control

A modern sintering furnace offers highly precise temperature control, often within a single degree. This is critical because ceramic materials like zirconia must reach a specific temperature to achieve maximum density and strength without being over-fired, which can cause brittleness.

This precision ensures every restoration has the optimal material properties for clinical longevity.

Ensuring a Perfect Fit

The furnace's ability to manage programmable heating and cooling cycles, known as ramp rates, is crucial. Controlled cooling prevents thermal shock, which can introduce micro-fractures into the ceramic.

This meticulous process guarantees dimensional accuracy, ensuring the final crown or bridge fits the patient's preparation perfectly without extensive manual adjustments.

The Role of Atmosphere Control

Many advanced furnaces incorporate vacuum technology or atmosphere controls. This removes oxygen and other contaminants from the chamber during the sintering cycle.

Eliminating these impurities prevents discoloration and ensures a pure, monolithic final restoration with maximum strength and biocompatibility.

The Impact on Lab Productivity and Economics

Beyond clinical quality, a sintering furnace fundamentally changes the business operations of a dental lab or clinic for the better.

Drastic Time Savings

Bringing sintering in-house eliminates the need to ship restorations to an external laboratory. This simple change can reduce the turnaround time for a crown from days to mere hours.

This allows for same-day restorations in some cases, vastly improving the patient experience and increasing case throughput.

Significant Cost Reduction

While there is an initial investment, a furnace delivers strong economic benefits. It reduces direct labor costs associated with manual processing and eliminates the fees paid to third-party labs.

Over time, these savings make the furnace a highly profitable asset that pays for itself.

Versatility Across Materials

Modern furnaces are not limited to a single material. They show strong adaptability to various dental ceramics, including different types of zirconia and other glass-ceramics.

This versatility means a single piece of equipment can support a wide range of restorative services, maximizing the return on investment.

Understanding Key Features and Considerations

When evaluating a furnace, specific features directly influence its performance and suitability for your needs. Understanding these is key to making a wise choice.

Chamber Size and Throughput

The chamber size determines how many restorations can be sintered in a single cycle. A larger chamber is more efficient for high-volume labs, while a smaller one may be perfect for a single-dentist clinic.

Heating Elements and Longevity

The heating elements are the heart of the furnace. Silicon carbide (SiC) elements are often preferred for their durability and ability to provide clean, stable heat, contributing to consistent results.

Programmability and Ease of Use

A furnace with a user-friendly interface and pre-set, customizable programs for different materials simplifies the workflow. This reduces the chance of human error and ensures repeatable, high-quality outcomes every time.

Making the Right Choice for Your Goal

Your specific objectives will determine which advantages of a sintering furnace are most important for your practice or lab.

- If your primary focus is clinical quality and fit: Prioritize a furnace with the most precise temperature control, programmable ramp rates, and vacuum capabilities.

- If your primary focus is efficiency and cost savings: Look for a furnace that matches your volume needs and offers fast cycles to maximize in-house production and eliminate external lab fees.

- If your primary focus is future-proofing and versatility: Choose a furnace with a broad temperature range and the adaptability to handle the wide array of ceramic materials on the market today and tomorrow.

Ultimately, integrating a dental sintering furnace empowers you to control the entire restoration process, delivering a higher standard of care more efficiently.

Summary Table:

| Advantage | Key Benefit | Impact |

|---|---|---|

| Superior Restoration Quality | Precise temperature and atmosphere control | Ensures strong, accurate, and biocompatible restorations |

| Increased Efficiency | Fast in-house sintering cycles | Reduces turnaround times and enables same-day procedures |

| Economic Benefits | Lower labor and external lab costs | Improves profitability and return on investment |

| Versatility | Adaptable to various dental ceramics | Supports a wide range of restorative services |

Ready to elevate your dental lab's capabilities?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for dental professionals like you. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs.

Transform your restoration process with superior quality, efficiency, and cost savings—contact us today to discuss how our sintering furnaces can benefit your practice!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations