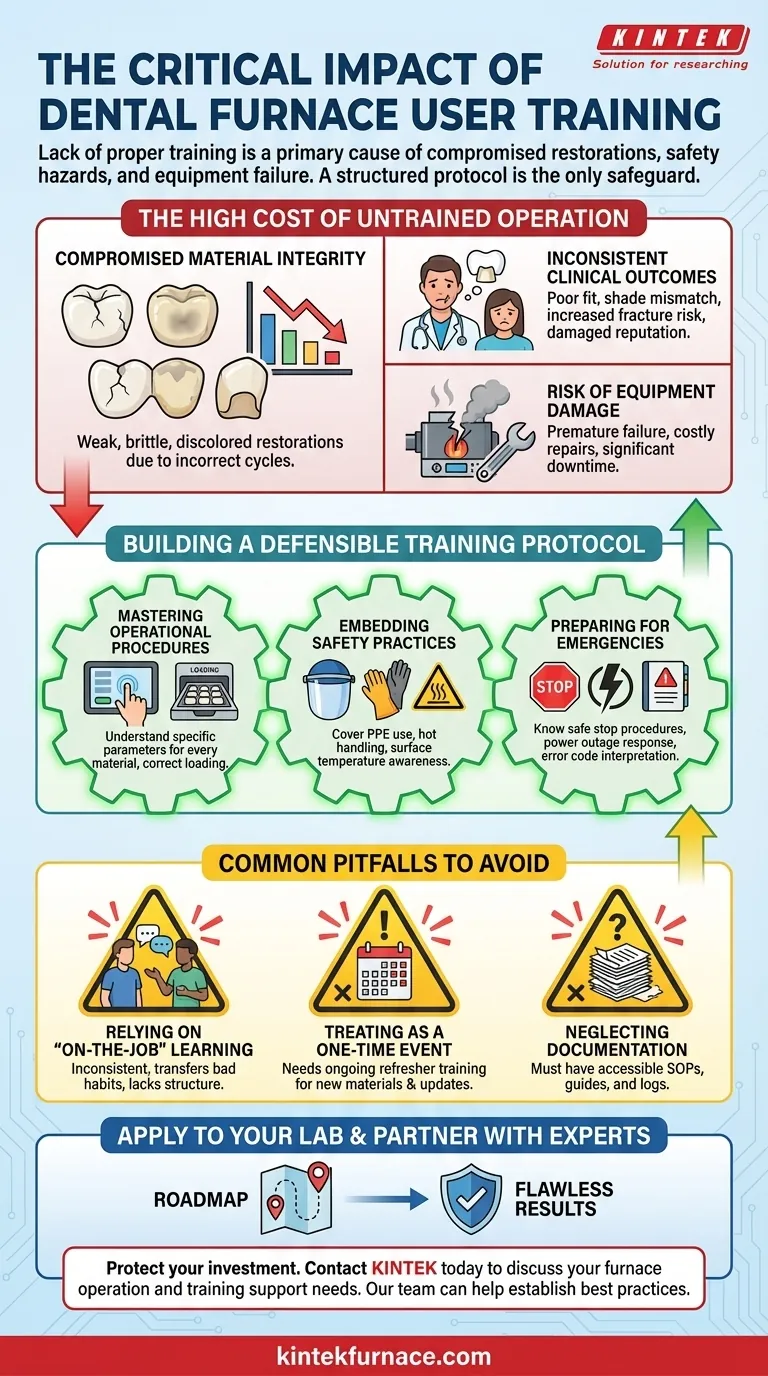

Ultimately, a lack of proper user training is a critical failure point in the operation of a dental furnace, directly leading to a wide range of sintering mistakes. This issue is best addressed by ensuring every person who operates the equipment undergoes a comprehensive training program that covers not just basic operation, but also crucial safety and emergency protocols.

Operator error due to insufficient training is not a minor inconvenience; it's a primary cause of compromised dental restorations, inconsistent clinical outcomes, and potential safety hazards. A structured, mandatory training protocol is the only reliable safeguard.

The High Cost of Untrained Operation

An untrained or poorly trained operator introduces significant risk into the dental laboratory's workflow. The consequences extend far beyond a single failed restoration, impacting material integrity, equipment longevity, and lab reputation.

Compromised Material Integrity

The most immediate impact is on the quality of the final product. Incorrectly programmed sintering cycles, temperatures, or hold times can result in weak, brittle, or discolored zirconia and other ceramic restorations.

These mistakes directly undermine the physical and aesthetic properties designed into the materials, leading to failures in the clinical setting.

Inconsistent Clinical Outcomes

When material integrity is compromised, the clinical outcomes become unpredictable. Crowns may not fit properly, shades can be off, and the risk of fracture increases dramatically.

This inconsistency erodes trust between the dental lab and the clinicians it serves, damaging the lab's reputation and potentially leading to lost business.

Risk of Equipment Damage

Dental furnaces are sophisticated and sensitive pieces of equipment. An operator lacking proper knowledge might overlook critical maintenance alerts, improperly load the sintering chamber, or fail to perform routine cleaning.

These seemingly small oversights can accumulate, leading to premature component failure, costly repairs, and significant operational downtime.

Building a Defensible Training Protocol

Simply having a senior technician "show the new person how it works" is not training. A robust training program is a formal, documented process that ensures consistency and complete understanding, regardless of who is operating the furnace.

Mastering Operational Procedures

Effective training goes beyond pushing the start button. It must cover the specific sintering parameters for every material used in the lab, from zirconia to various ceramics.

Operators must understand how to select, modify, and verify programs, as well as the correct procedures for loading and unloading the furnace to ensure even heat distribution.

Embedding Safety Practices

The high temperatures involved in sintering present inherent risks. Training must explicitly cover safety protocols, including the use of personal protective equipment (PPE), proper handling of hot sintering trays, and awareness of the furnace's external surface temperatures.

Preparing for Emergencies

Every operator must know precisely what to do when something goes wrong. A comprehensive training program covers emergency protocols, such as how to safely stop a cycle mid-process, what to do during a power outage, and how to interpret and respond to common error codes.

Common Pitfalls to Avoid

Implementing a training program is the first step, but avoiding common pitfalls is what makes it effective and sustainable.

Relying Solely on "On-the-Job" Learning

Informal, "shadowing" style learning is inconsistent and often leads to the transfer of bad habits. It lacks the structure to ensure all critical safety and operational details are covered thoroughly.

Treating Training as a One-Time Event

Training is not a set-it-and-forget-it activity. As new materials are introduced, furnace software is updated, or staff roles change, ongoing refresher training is essential to maintain a high standard of operation.

Neglecting Documentation

An effective program is supported by clear, accessible documentation. This includes written standard operating procedures (SOPs), quick-reference guides near the furnace, and maintenance logs. Documentation ensures every operator adheres to the same proven process.

How to Apply This to Your Lab

To transform your furnace operations from a point of uncertainty into a pillar of reliability, tailor your training to your most critical goals.

- If your primary focus is quality and consistency: Mandate standardized training on the specific sintering protocols for every material you use, reinforced with clear documentation and checklists.

- If your primary focus is safety and compliance: Implement formal, documented training on all safety practices and emergency procedures, with annual recertification for all operators.

- If your primary focus is efficiency and uptime: Train all users on routine maintenance checks, proper loading techniques, and first-level troubleshooting to minimize errors and equipment downtime.

Ultimately, investing in your operators is a direct investment in the quality of your work and the longevity of your equipment.

Summary Table:

| Impact of Poor Training | Consequence |

|---|---|

| Compromised Material Integrity | Weak, brittle, or discolored zirconia crowns and bridges. |

| Inconsistent Clinical Outcomes | Poor-fitting restorations and damaged lab reputation. |

| Risk of Equipment Damage | Premature component failure, costly repairs, and downtime. |

Protect your investment and ensure flawless results. Don't let operator error compromise your lab's output. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for unique needs. Our team can help you establish best practices for your equipment. Contact KINTEL today to discuss your furnace operation and training support needs.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations