Ignoring the preheat and cooldown phases in a dental furnace is a critical error. It is essential to follow these steps precisely because skipping or rushing them induces thermal shock, a rapid and uneven temperature change that causes the dental ceramic to crack. Adhering to the manufacturer's specified heating and cooling rates is the only way to ensure the final restoration is strong, durable, and free from structural defects.

The controlled temperature changes during preheating and cooldown are not optional steps; they are fundamental to managing material stress. Rushing this process subjects the ceramic to thermal shock, creating micro-fractures that can lead to the premature failure of the restoration.

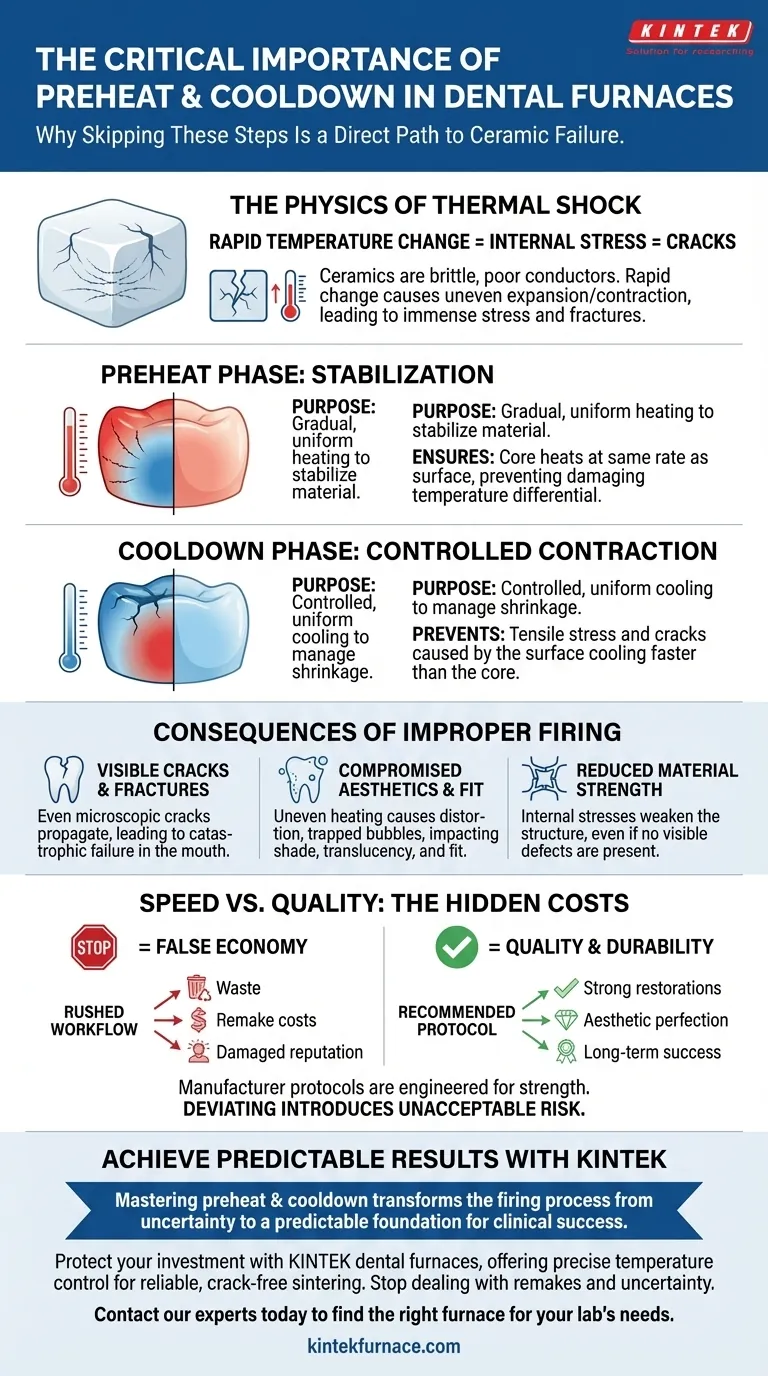

The Physics of Thermal Shock in Dental Ceramics

To understand why these phases are non-negotiable, we must first understand the material you're working with. Dental ceramics are brittle and are poor conductors of heat. This combination makes them highly susceptible to stress from sudden temperature changes.

What is Thermal Shock?

Thermal shock occurs when different parts of a single material expand or contract at different rates due to a rapid temperature change.

This creates immense internal stress. Because ceramics have low ductility, they cannot deform to accommodate this stress; instead, they crack.

The Role of the Preheat Phase

The preheat phase is designed to raise the temperature of the entire restoration slowly and uniformly.

This gradual process ensures that the core of the ceramic heats up at the same rate as the surface, preventing a damaging temperature differential. This stabilizes the material for the intense heat of the main sintering cycle.

The Critical Cooldown Phase

Similarly, the cooldown phase allows the restoration to shrink in a controlled, uniform manner as it cools.

If a restoration is cooled too quickly, the outer surface will contract rapidly while the inner core remains hot and expanded. This pulls the surface inward, creating tensile stress that is the primary cause of cracks and fractures.

Consequences of Improper Firing

Deviating from the recommended firing schedule is not a shortcut; it's a direct path to compromised results that waste time, materials, and trust.

Visible Cracks and Fractures

This is the most obvious outcome of thermal shock. Even microscopic cracks, invisible to the naked eye, can propagate under normal occlusal forces, leading to a catastrophic failure of the restoration in the patient's mouth.

Compromised Aesthetics and Fit

Uneven heating and cooling can also cause distortion or trap bubbles within the ceramic. This negatively impacts the final shade and translucency. More importantly, it can alter the restoration's dimensions, compromising the precise fit required for proper adhesion and long-term success.

Reduced Material Strength

Even if a restoration emerges from the furnace with no visible defects, its structural integrity may already be compromised. Internal stresses created by improper firing protocols weaken the entire structure, meaning it will not perform to the manufacturer's specified strength.

Understanding the Trade-offs: Speed vs. Quality

In any production environment, the temptation to accelerate the workflow is always present. However, with dental furnaces, this is a trade-off that is never worth making.

The Lure of a Faster Workflow

It can seem efficient to shorten preheat or cooldown cycles to increase the daily output of a lab. This is a false economy.

The Hidden Costs of Rushing

The cost of a single remake—factoring in materials, technician labor, and clinical chair time—far outweighs any time saved by cutting corners on the firing cycle. A failed restoration damages the reputation of the lab and the clinician.

The Manufacturer's Protocol is Not a Suggestion

Manufacturers invest significant resources to develop firing schedules tailored to their material's specific properties, such as its coefficient of thermal expansion. These protocols are engineered to produce the strongest, most aesthetic result possible. Deviating from them introduces unacceptable risk.

Making the Right Choice for Your Goal

To ensure every restoration meets the highest standards of quality and durability, you must treat the firing process with precision and respect for the materials.

- If your primary focus is consistency: Always adhere strictly to the manufacturer's operational manual for both the material and the furnace.

- If you are troubleshooting failures: Re-examine your preheat and cooldown protocols first, as they are the most common source of cracks and fractures.

- If you are investing in new equipment: Prioritize a furnace known for its precise temperature control and reliability to minimize variables in your firing process.

Ultimately, mastering the preheat and cooldown phases transforms the firing process from a source of uncertainty into a predictable foundation for clinical success.

Summary Table:

| Firing Phase | Purpose | Risk of Skipping |

|---|---|---|

| Preheat | Gradual, uniform heating to stabilize material | Internal stress, micro-fractures |

| Cooldown | Controlled, uniform cooling to manage shrinkage | Cracks, distortion, compromised fit |

Achieve predictable, high-quality results with every firing.

Rushing the preheat and cooldown phases is the leading cause of ceramic failure. Protect your investment in materials and technician time by using a furnace engineered for precision.

Backed by expert R&D and manufacturing, KINTEK offers advanced dental furnaces with precise temperature control for reliable, crack-free sintering. Our systems are built to follow the most demanding manufacturer protocols, ensuring your restorations are strong, durable, and aesthetically perfect.

Stop dealing with remakes and uncertainty. Contact our experts today to find the right furnace for your lab's unique needs.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency