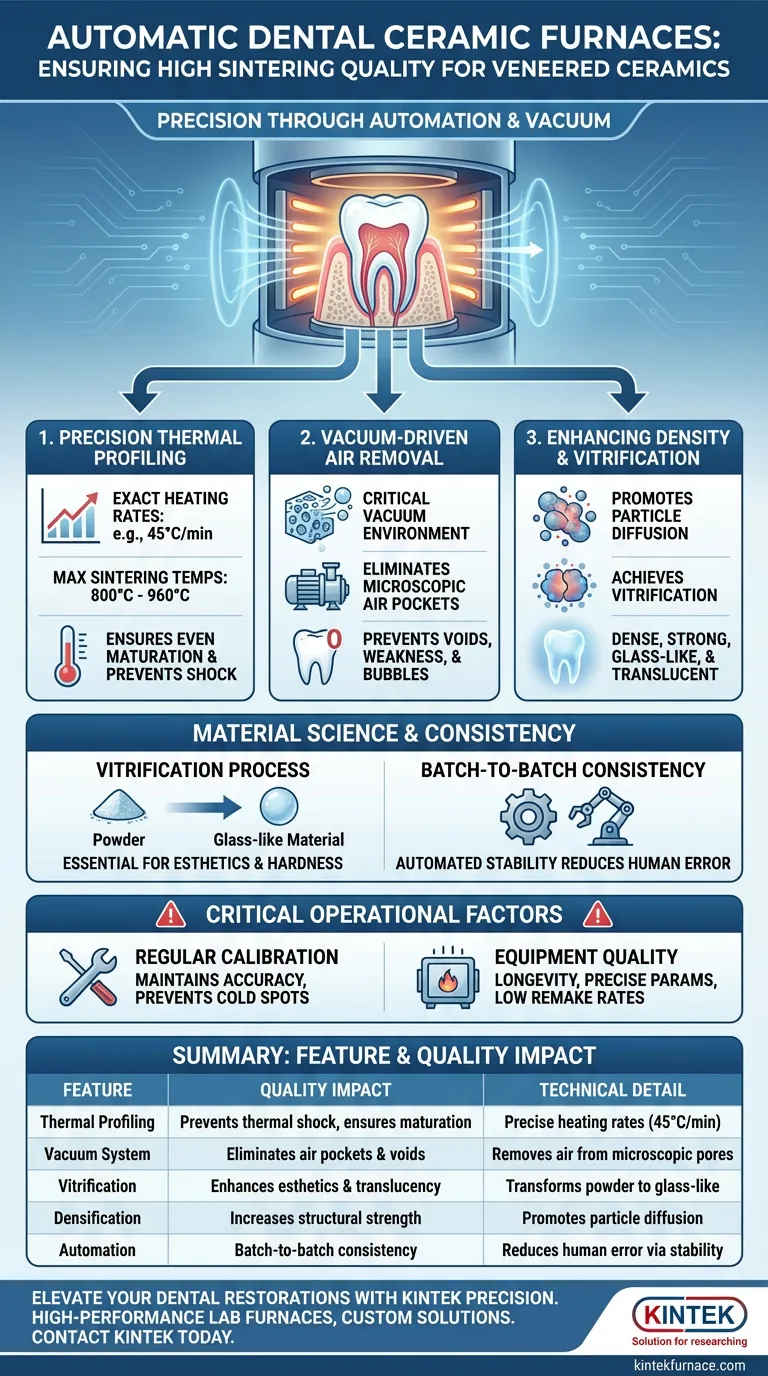

Automatic dental ceramic furnaces guarantee high sintering quality through the precise, automated synchronization of heating rates, maximum temperatures, and vacuum pressure. By establishing a strictly controlled vacuum environment, these devices actively extract air from the ceramic pores during the firing cycle. This process facilitates particle diffusion and densification, yielding a final restoration with high material density and minimal porosity.

The core mechanism for quality lies in the vacuum-assisted elimination of air pockets combined with programmed thermal stability. This ensures the ceramic achieves full densification and the specific vitrification required for both structural durability and esthetic translucency.

The Mechanics of Quality Control

Precision in Thermal Profiling

To prevent thermal shock and ensure even firing, automatic furnaces utilize exact heating rates, such as 45°C per minute.

They hold the material at specific maximum sintering temperatures, typically ranging between 800°C and 960°C depending on the material.

This programmed accuracy ensures that every layer of the veneered ceramic receives the exact thermal energy required for proper maturation.

Vacuum-Driven Air Removal

The most critical feature for veneered ceramics is the application of a vacuum environment.

This mechanism physically pulls air out of the microscopic pores within the ceramic powder build-up.

By removing this air, the furnace eliminates potential voids that would otherwise result in structural weaknesses or visible bubbles in the final glaze.

Enhancing Material Density

The combination of heat and vacuum promotes particle diffusion.

As particles merge, the material undergoes densification, significantly reducing the porosity of the veneer.

This results in a restoration that is not only stronger but also smoother and more hygienic for the patient.

Material Science Principles

Achieving Vitrification

Beyond simple drying, the furnace drives the ceramic materials to undergo vitrification.

This process transforms the ceramic powder into a glass-like material, which is essential for replicating the optical properties of natural teeth.

Vitrification enhances the esthetic result by creating depth and translucency while simultaneously hardening the surface.

Batch-to-Batch Consistency

Automatic furnaces utilize advanced pressure and temperature control systems to maintain process stability.

This removes the variable of human error from the firing equation.

Consequently, laboratories can ensure that the quality of dental restorations remains consistent across different production batches.

Critical Operational Factors

The Necessity of Calibration

While these furnaces are highly automated, they are complex machines that are subject to sensor drift over time.

Regular maintenance and calibration are non-negotiable to maintain the accuracy of the temperature and vacuum levels.

Failure to service the unit can lead to "cold spots" or insufficient vacuum, instantly compromising the integrity of the veneer.

The Impact of Equipment Quality

Not all heating elements and vacuum pumps provide the same longevity or precision.

Investing in a unit with a reputation for durability ensures that the firing parameters remain true over thousands of cycles.

Cheaper units may struggle to maintain the strict vacuum levels required for high-end esthetic work, leading to higher remake rates.

Ensuring Consistent Clinical Success

To maximize the capabilities of your automatic dental furnace, align your operational protocols with your specific output goals:

- If your primary focus is Esthetics: Prioritize vacuum calibration checks, as proper air removal is the single most important factor for achieving flawless translucency and preventing bubbling.

- If your primary focus is Strength and Durability: Ensure your specific firing programs (heating rate and hold time) strictly match the ceramic manufacturer’s guidelines to guarantee full particle densification.

By leveraging the automated precision of these furnaces, you convert raw ceramic powder into a dense, biocompatible, and glass-like restoration that withstands the rigors of the oral environment.

Summary Table:

| Feature | Quality Impact | Technical Detail |

|---|---|---|

| Thermal Profiling | Prevents thermal shock & ensures maturation | Precise heating rates (e.g., 45°C/min) |

| Vacuum System | Eliminates air pockets & voids | Removes air from microscopic ceramic pores |

| Vitrification | Enhances esthetics & translucency | Transforms powder into glass-like material |

| Densification | Increases structural strength | Promotes particle diffusion and low porosity |

| Automation | Batch-to-batch consistency | Reduces human error via programmed stability |

Elevate Your Dental Restorations with KINTEK Precision

Achieving the perfect balance of translucency and strength requires equipment that never wavers. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of high-performance lab furnaces, including specialized Muffle, Tube, Vacuum, and CVD systems—all customizable to meet the exacting needs of modern dental laboratories and material research.

Don't let equipment drift compromise your clinical success. Experience the power of precise thermal control and superior vacuum technology designed for durability. Contact KINTEK today to find your custom furnace solution and ensure every restoration meets the highest standard of excellence.

Visual Guide

References

- Moritz Hoffmann, Bogna Stawarczyk. Mechanical Properties of High- and Low-Fusing Zirconia Veneering Ceramics Fired on Different Trays and Substrates. DOI: 10.3390/ma17102261

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the process for correcting open proximal contacts using ceramic add-on material? Master Precision Dental Restoration

- What are the advantages of using a zirconia sintering furnace in terms of result consistency? Achieve Reliable Dental Restorations

- How can incorrect temperature settings be prevented in dental furnaces? Ensure Precision for Perfect Restorations

- What temperature range do pressing furnaces typically operate at? Optimize Your Dental Lab's Ceramic Pressing

- What are ceramic combination furnaces used for? Streamline Dental Lab Workflows with Dual Firing and Pressing

- How are modern dental furnaces controlled and what advantages do they offer? Enhance Your Dental Lab's Precision and Efficiency

- What types of dental prosthetics are made using dental ceramics? Discover the Best Options for Your Smile

- What types of dental furnaces are available? Choose the Right Furnace for Your Dental Lab Needs