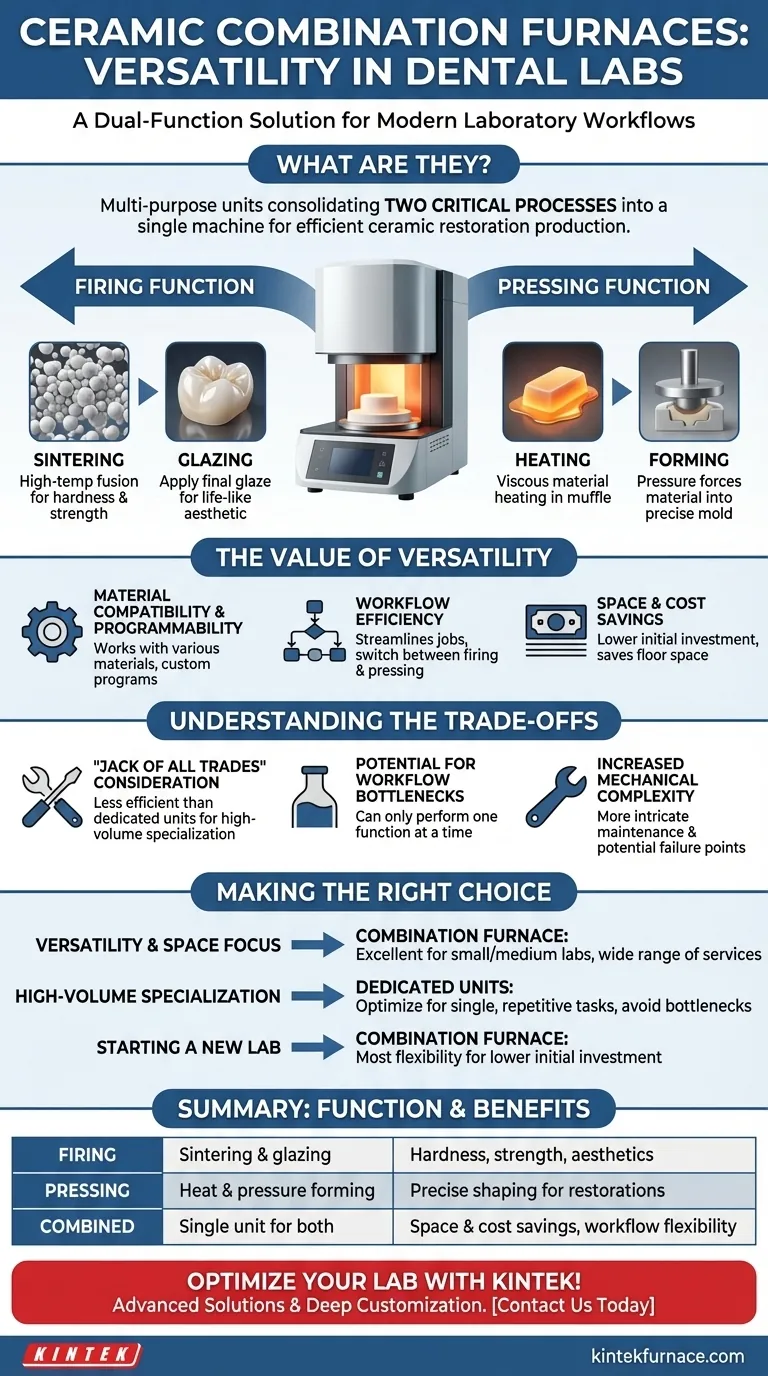

At their core, ceramic combination furnaces are multi-purpose units designed for the modern dental laboratory. They consolidate two critical, distinct processes into a single machine: the conventional firing of ceramic restorations and the pressing of all-ceramic materials into their final form.

The central value of a combination furnace is its versatility. It merges the capabilities of a dedicated firing oven and a press furnace, allowing a dental lab to save space, streamline workflows, and handle a wide variety of ceramic materials with a single piece of equipment.

The Dual Functions: Firing and Pressing Explained

To understand the utility of a combination furnace, you must first understand the two core processes it facilitates. These are fundamental to creating durable and aesthetic dental restorations like crowns, veneers, and bridges.

Ceramic Firing: The Glazing and Sintering Process

Firing is a high-temperature heat treatment process. Its primary goal is to mature the ceramic material, a process known as sintering, where ceramic particles fuse together to achieve their final hardness, strength, and stability.

This function is also used for applying a final glaze. A thin layer of glass is fired onto the restoration's surface to create a smooth, non-porous, and life-like appearance that mimics natural enamel.

Ceramic Pressing: Forming the Restoration

Pressing is a fabrication technique that uses both heat and pressure. A pre-made ceramic ingot is heated until it becomes viscous, like thick honey, within the furnace's muffle.

Once the material reaches the correct plasticity, a plunger (often pneumatic) applies pressure. This forces the softened ceramic into a void within a pre-made investment mold, precisely replicating the shape of the final restoration. This method is common for materials like lithium disilicate.

The Value of Versatility in a Modern Lab

The "combination" aspect is not just a feature; it's a strategic advantage for many dental laboratories.

Material Compatibility and Programmability

These furnaces are designed to work with a vast array of dental materials from different manufacturers. They come with pre-set programs for common ceramics but also offer the crucial ability for technicians to create and save custom programs to meet specific material requirements or aesthetic goals.

Workflow Efficiency

A single unit that can handle both a complex layered crown (firing) and a monolithic pressed veneer (pressing) provides immense flexibility. A technician can switch between different types of jobs without moving to a different machine, streamlining the lab's daily production schedule.

Space and Cost Savings

For small or medium-sized labs, floor space is a premium. A combination furnace occupies the footprint of one machine, not two. This also translates to a lower initial capital investment compared to purchasing separate, dedicated firing and pressing units.

Understanding the Trade-offs

While highly versatile, a combination furnace is not the universal solution for every laboratory. Objectivity requires acknowledging its potential limitations.

The "Jack of All Trades" Consideration

A machine engineered to perform two different tasks may not execute a single task with the same focused efficiency as a dedicated unit. For extremely high-volume, specialized production—such as a lab that only presses crowns—a dedicated press furnace might offer more robust performance or faster cycle times.

The Potential for Workflow Bottlenecks

The most significant trade-off is that the furnace can only perform one function at a time. In a busy lab with a high volume of both firing and pressing work, a single combination unit can become a bottleneck. Two separate machines, by contrast, could run concurrently, doubling the throughput.

Increased Mechanical Complexity

By integrating a pressing mechanism, vacuum systems, and sophisticated heating controls, a combination furnace is inherently more complex than a simple firing oven. This can sometimes lead to more intricate maintenance requirements and more potential points of failure over the machine's lifespan.

Making the Right Choice for Your Lab

Selecting the right equipment depends entirely on your lab's specific business goals, production volume, and service offerings.

- If your primary focus is versatility and space efficiency: A combination furnace is an excellent choice for small to medium-sized labs or those offering a wide range of restorative services.

- If your primary focus is high-volume, specialized production: Consider investing in dedicated firing and pressing units to avoid bottlenecks and optimize for a single, repetitive task.

- If you are starting a new lab: A combination furnace provides the most flexibility for a lower initial investment, allowing you to adapt and scale your services as the business grows.

Understanding the balance between integrated versatility and dedicated specialization is the key to equipping your laboratory for optimal efficiency and success.

Summary Table:

| Function | Description | Key Benefit |

|---|---|---|

| Firing | High-temperature sintering and glazing of ceramics | Achieves hardness, strength, and aesthetic finish |

| Pressing | Heat and pressure forming of ceramic ingots into molds | Precise shaping for crowns, veneers, and bridges |

| Combined Use | Single unit handling both processes | Saves space, reduces costs, and enhances workflow flexibility |

Ready to optimize your dental lab with a versatile ceramic combination furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for dental laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs. Contact us today to learn how our furnaces can enhance your efficiency and material handling!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency