Dental ceramics are the foundational material for many of modern dentistry's most common restorations. Due to their exceptional aesthetics and biocompatibility, materials like porcelain and zirconia are used to fabricate a range of prosthetics, including full-coverage crowns, cosmetic veneers, and multi-tooth bridges that restore both function and appearance.

The versatility of dental ceramics allows them to solve distinct clinical problems. The choice of prosthetic—from a thin veneer to a full bridge—is determined by whether the goal is a purely cosmetic enhancement, the protection of a single damaged tooth, or the complete replacement of missing teeth.

The Role of Ceramics in Dental Restoration

Dental ceramics have become the material of choice because they uniquely satisfy the two primary demands of dental work: function and aesthetics. They are designed to withstand the forces of chewing while being virtually indistinguishable from natural teeth.

Why Ceramics? The Core Properties

The primary advantage of ceramics is their ability to mimic the translucency and color of natural tooth enamel, making them ideal for visible areas of the mouth. They are also biocompatible, meaning they do not cause irritation or allergic reactions in the surrounding gum tissues. Finally, modern ceramics offer high compressive strength and wear resistance.

From Cosmetic Enhancement to Full Reconstruction

The application of ceramics is not one-size-fits-all. The type of prosthetic chosen depends entirely on the underlying structural and aesthetic problem. A small chip on a front tooth requires a very different solution than a molar that has had a root canal.

A Breakdown of Common Ceramic Prosthetics

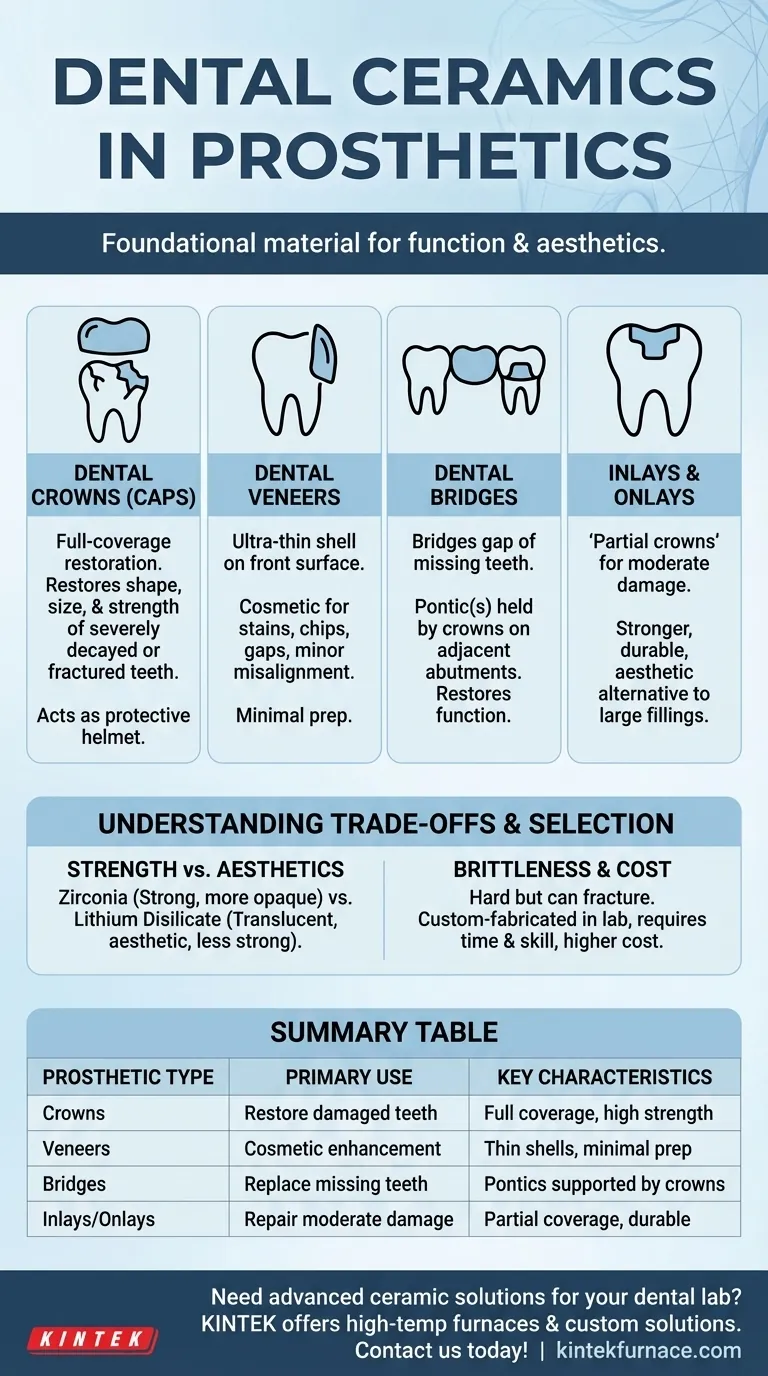

Each type of ceramic prosthetic is engineered to address a specific clinical need, from minor repairs to major reconstructions.

Dental Crowns (Caps)

A dental crown is a full-coverage restoration that completely encases the visible portion of a damaged tooth. It acts as a protective helmet.

Crowns are used to restore teeth that are severely decayed, fractured, or have undergone root canal therapy. They restore the tooth's original shape, size, and strength. While some crowns fuse porcelain to a metal substructure (PFM), all-ceramic crowns (made from materials like zirconia or lithium disilicate) offer superior aesthetics.

Dental Veneers

A veneer is an ultra-thin shell of porcelain or ceramic bonded directly to the front surface of a tooth. Its purpose is almost entirely cosmetic.

Veneers are the go-to solution for correcting imperfections like stains, chips, small gaps, or minor misalignment. Because they only cover the front, they require significantly less tooth preparation than a full crown, making them a more conservative treatment for aesthetic enhancements.

Dental Bridges

A dental bridge is a prosthetic designed to "bridge" a gap created by one or more missing teeth. It is typically composed of one or more artificial teeth, called pontics, held in place by crowns on the adjacent natural teeth (abutments).

Ceramics are essential for bridges, providing the aesthetic appearance for the replacement pontic(s) and the strength and durability for the anchoring crowns.

Inlays and Onlays

Often called "partial crowns," inlays and onlays are custom-fabricated ceramic restorations used to repair teeth with damage that is too extensive for a simple filling but not severe enough to require a full crown.

An inlay fits within the cusps (bumps) of a tooth, while an onlay extends over one or more of the cusps. They provide a stronger, more durable, and more aesthetic solution than large, traditional fillings.

Understanding the Trade-offs

While highly effective, ceramic restorations are not without limitations. The choice of material and prosthetic involves balancing competing factors.

Strength vs. Aesthetics

There is often a trade-off between the strength and translucency of different ceramic materials. For example, zirconia is exceptionally strong and fracture-resistant, making it ideal for crowns on back molars, but it can appear more opaque. Materials like lithium disilicate offer excellent translucency for highly aesthetic veneers and front-tooth crowns but may not be suitable for high-stress applications.

Brittleness and Fracture Risk

Although ceramics are very hard, they can be brittle. A restoration that is not properly fitted, an unbalanced bite, or trauma can cause the ceramic to chip or fracture. This risk is a critical consideration in material selection and prosthetic design.

Cost and Fabrication

Ceramic prosthetics are custom-fabricated in a dental laboratory, a process that requires significant skill and time. This makes them more expensive and requires at least two dental appointments compared to a direct restoration like a composite filling.

Matching the Prosthetic to the Clinical Need

The decision-making process is guided by the specific problem you need to solve.

- If your primary focus is correcting cosmetic imperfections on front teeth: A ceramic veneer offers the most conservative and aesthetic solution.

- If your primary focus is restoring a single, heavily damaged or root-canal-treated tooth: A full ceramic crown is the standard of care for providing strength and 360-degree protection.

- If your primary focus is replacing one or more missing teeth using adjacent teeth for support: A ceramic bridge is the established method for filling the space and restoring function.

- If your primary focus is repairing a large cavity without removing excessive tooth structure: A ceramic inlay or onlay provides a durable and aesthetic alternative to both large fillings and full crowns.

Ultimately, selecting the right ceramic prosthetic is a clinical decision that balances structural requirements with aesthetic goals.

Summary Table:

| Prosthetic Type | Primary Use | Key Characteristics |

|---|---|---|

| Dental Crowns | Restore damaged teeth | Full coverage, high strength, aesthetic |

| Dental Veneers | Cosmetic enhancement | Thin shells, minimal tooth prep |

| Dental Bridges | Replace missing teeth | Pontics supported by crowns |

| Inlays/Onlays | Repair moderate damage | Partial coverage, durable alternative to fillings |

Need advanced ceramic solutions for your dental lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise solutions for your unique experimental needs, enhancing efficiency and outcomes. Contact us today to discuss how we can support your laboratory!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab