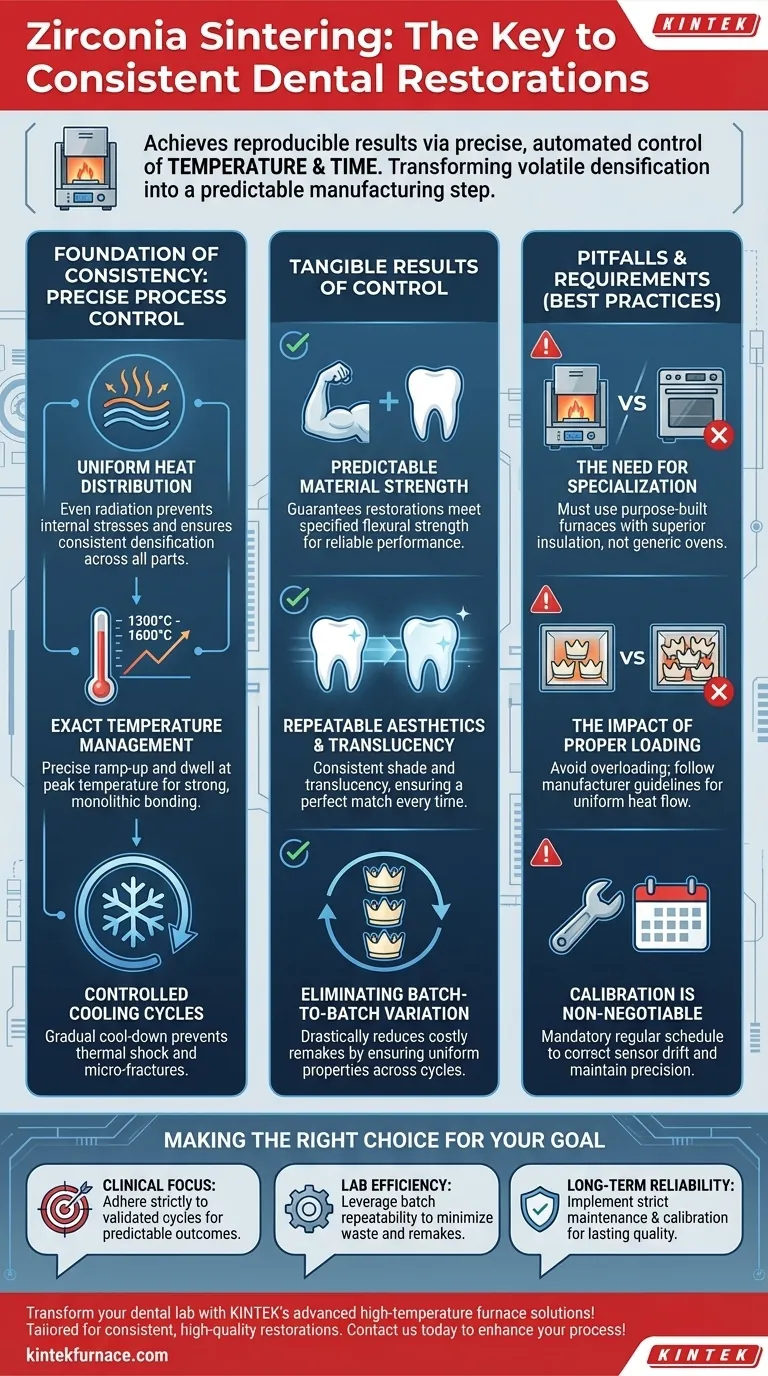

For any dental lab or clinician, the primary advantage of a modern zirconia sintering furnace is its ability to deliver exceptionally consistent and reproducible results. This reliability stems from its precise, automated control over the two most critical variables in the sintering process: temperature and time. By managing the entire thermal cycle, the furnace ensures every restoration achieves the desired density, strength, and aesthetic quality.

The consistency of a zirconia sintering furnace is not a feature, but the direct outcome of its core design. It transforms the volatile process of ceramic densification into a predictable, repeatable manufacturing step by meticulously controlling every phase of the heating and cooling cycle.

The Foundation of Consistency: Precise Process Control

A specialized zirconia furnace doesn't just get hot; it manages a complex thermal journey. This control is what separates a high-quality restoration from a failure.

Uniform Heat Distribution

The process begins with advanced heating elements designed to radiate heat evenly throughout the sintering chamber. This uniformity is critical for ensuring that all parts of every restoration—whether a single crown or a full-arch bridge—densify at the same rate, preventing internal stresses and weak spots.

Exact Temperature Management

Zirconia must be heated gradually to a specific peak temperature, typically between 1300°C and 1600°C. The furnace's controller precisely executes this ramp-up, then holds that peak temperature during a "dwell" or "soaking" stage. This phase is when the zirconia particles bond and densify, creating a strong, monolithic structure.

Controlled Cooling Cycles

Just as important as the heating is the cooling. A controlled, gradual cool-down prevents thermal shock, which can cause micro-fractures and compromise the integrity of the final restoration. This managed process ensures the material is stable and stress-free.

The Tangible Results of Sintering Control

This level of process control directly translates into predictable, high-quality outcomes that labs and their clients can depend on.

Predictable Material Strength

By ensuring proper and complete densification, the furnace produces restorations that consistently meet their specified flexural strength. This removes the guesswork and provides confidence that the restoration will perform as expected in the patient's mouth.

Repeatable Aesthetics and Translucency

The final shade and translucency of zirconia are heavily influenced by the sintering cycle. A consistent process guarantees that the aesthetic outcome of a restoration today will be identical to one produced weeks or months from now, ensuring a perfect match every time.

Eliminating Batch-to-Batch Variation

For a production environment, this is the ultimate advantage. A properly calibrated furnace eliminates variation between different sintering cycles. This means every batch of crowns or bridges will have the same physical and aesthetic properties, drastically reducing the need for costly remakes.

Understanding the Pitfalls and Requirements

Achieving this consistency requires more than just owning the equipment. The furnace is a precision instrument that must be operated correctly.

The Need for Specialization

You cannot use a generic high-temperature oven for zirconia. Sintering furnaces are purpose-built with superior insulation and non-contaminating heating elements specifically for the chemical and physical demands of zirconia ceramics.

The Impact of Proper Loading

Consistency also depends on the operator. Overloading the chamber or placing restorations too close together can impede uniform heat flow, creating cold spots and inconsistent results. Following manufacturer guidelines for loading is essential.

Calibration is Non-Negotiable

Over time, the furnace's temperature sensors (thermocouples) can drift. To maintain the precision required for consistent results, a regular calibration schedule is not optional—it is a mandatory part of professional quality control.

Making the Right Choice for Your Goal

By understanding how a furnace achieves consistency, you can better leverage it to meet your specific operational needs.

- If your primary focus is clinical outcomes: Adhere strictly to the zirconia manufacturer's validated sintering cycles to guarantee predictable strength and aesthetics for every case.

- If your primary focus is lab efficiency: Leverage the furnace's batch-to-batch repeatability to minimize remakes, reduce material waste, and increase overall productivity.

- If your primary focus is long-term reliability: Implement a strict maintenance and calibration schedule to ensure your furnace remains a source of predictable quality for years to come.

Ultimately, mastering the sintering process transforms a critical production step from a variable into a reliable constant.

Summary Table:

| Key Advantage | Description |

|---|---|

| Precise Process Control | Automated management of temperature and time for uniform sintering cycles. |

| Uniform Heat Distribution | Even heating prevents internal stresses and ensures consistent densification. |

| Predictable Material Strength | Guarantees restorations meet specified flexural strength for reliable performance. |

| Repeatable Aesthetics | Consistent translucency and shade matching across all batches. |

| Eliminates Batch Variation | Reduces remakes and material waste with reliable, reproducible outcomes. |

Transform your dental lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide specialized zirconia sintering furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, tailored to your unique needs. Our deep customization capabilities ensure precise control for consistent, high-quality restorations—boosting efficiency and reducing costs. Contact us today to learn how we can enhance your sintering process and deliver reliable results!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision