To prevent incorrect temperature settings, you must combine two critical actions: always consult the specific material manufacturer’s guidelines for the correct firing cycle, and implement a schedule of routine calibration to ensure your dental furnace's temperature readings are accurate. These two steps work together to guarantee the temperature you set is the temperature your restorations actually experience.

The core challenge is not simply entering the right temperature, but ensuring the furnace achieves and maintains it accurately. Incorrect settings are often a symptom of either using the wrong protocol for the material or a furnace that has drifted from its factory calibration over time.

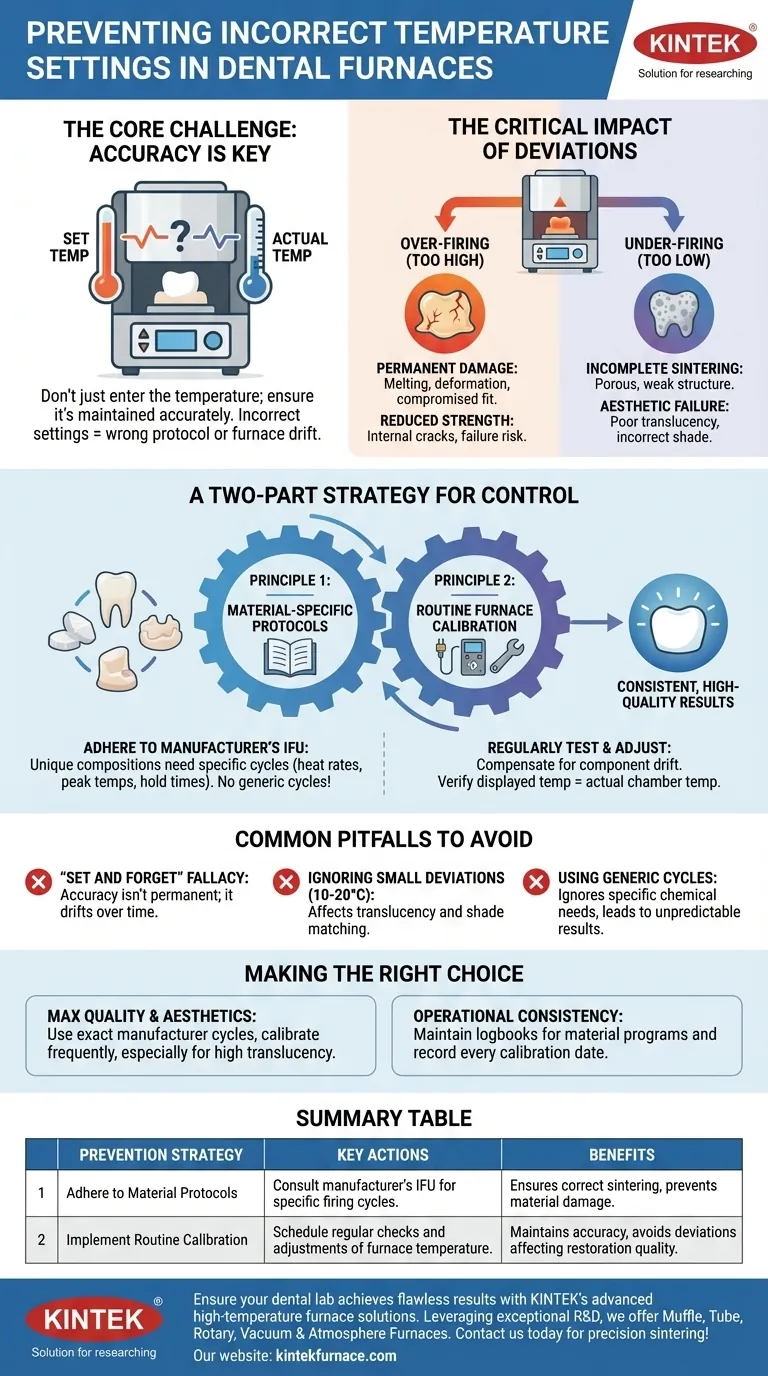

The Critical Impact of Temperature Deviations

A furnace's temperature is the single most important variable in the sintering process. Even minor inaccuracies can have a significant impact on the final restoration's structural integrity, fit, and aesthetics.

The Dangers of Over-Firing

When the furnace temperature is too high, even by a small margin, the dental material can be permanently damaged. This often results in melting or deformation, which compromises the fit of the restoration.

Even if the shape is maintained, excessive heat can cause internal cracks and reduce the material's strength, making it prone to failure in the patient's mouth.

The Risks of Under-Firing

If the furnace temperature is too low, the material will not achieve full sintering. This is a process where the individual particles fuse together to create a dense, strong final structure.

Incomplete sintering leaves the restoration porous and weak. It will lack the required durability and may not achieve the desired translucency or shade, leading to a functional and aesthetic failure.

A Two-Part Strategy for Temperature Control

Preventing these issues requires a disciplined, two-part approach that addresses both the firing program and the equipment's accuracy.

Principle 1: Adhere to Material-Specific Protocols

Never assume one sintering cycle works for all materials. Different types of zirconia and other ceramics have unique chemical compositions that demand very specific heating rates, peak temperatures, and hold times.

Always refer to the manufacturer's Instructions for Use (IFU) for the exact material you are working with. These are not suggestions; they are scientifically validated parameters required to achieve the material's advertised properties.

Principle 2: Implement Routine Furnace Calibration

A dental furnace is a precision instrument whose accuracy can drift over time due to the degradation of heating elements and thermocouples (the sensor that measures temperature).

Calibration is the process of testing your furnace's displayed temperature against a known, accurate reference and adjusting it if necessary. This is the only way to confirm that a setting of 1500°C results in an actual chamber temperature of 1500°C.

Common Pitfalls to Avoid

Many temperature-related failures stem from common oversights or incorrect assumptions about the equipment.

The "Set and Forget" Fallacy

A brand-new furnace is accurate out of the box, but it will not stay that way forever. Assuming its accuracy is permanent is a frequent cause of gradually declining restoration quality.

Ignoring Small Deviations

A temperature deviation of just 10-20°C might not cause a catastrophic melt, but it can still negatively affect properties like translucency and shade matching. These subtle failures still represent a quality control issue.

Using Generic Sintering Cycles

In a busy lab, it can be tempting to use a single "go-to" sintering program to save time. This practice is risky and ignores the specific chemical needs of different materials, leading to inconsistent and unpredictable results.

Making the Right Choice for Your Goal

Building a reliable system is about creating repeatable habits that ensure accuracy every time.

- If your primary focus is maximum quality and aesthetics: You must use the exact cycle recommended by the material manufacturer and calibrate your furnace frequently, especially when working with highly translucent materials.

- If your primary focus is operational consistency: Create a clear logbook to track material types with their corresponding programs and record every calibration date to ensure this critical maintenance step is never missed.

Ultimately, treating your furnace as a precision instrument that requires regular verification is the key to predictable, high-quality results.

Summary Table:

| Prevention Strategy | Key Actions | Benefits |

|---|---|---|

| Adhere to Material Protocols | Consult manufacturer's IFU for specific firing cycles | Ensures correct sintering, prevents material damage |

| Implement Routine Calibration | Schedule regular checks and adjustments of furnace temperature | Maintains accuracy, avoids deviations affecting restoration quality |

Ensure your dental lab achieves flawless results with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique needs. Contact us today to enhance precision and efficiency in your sintering processes!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations