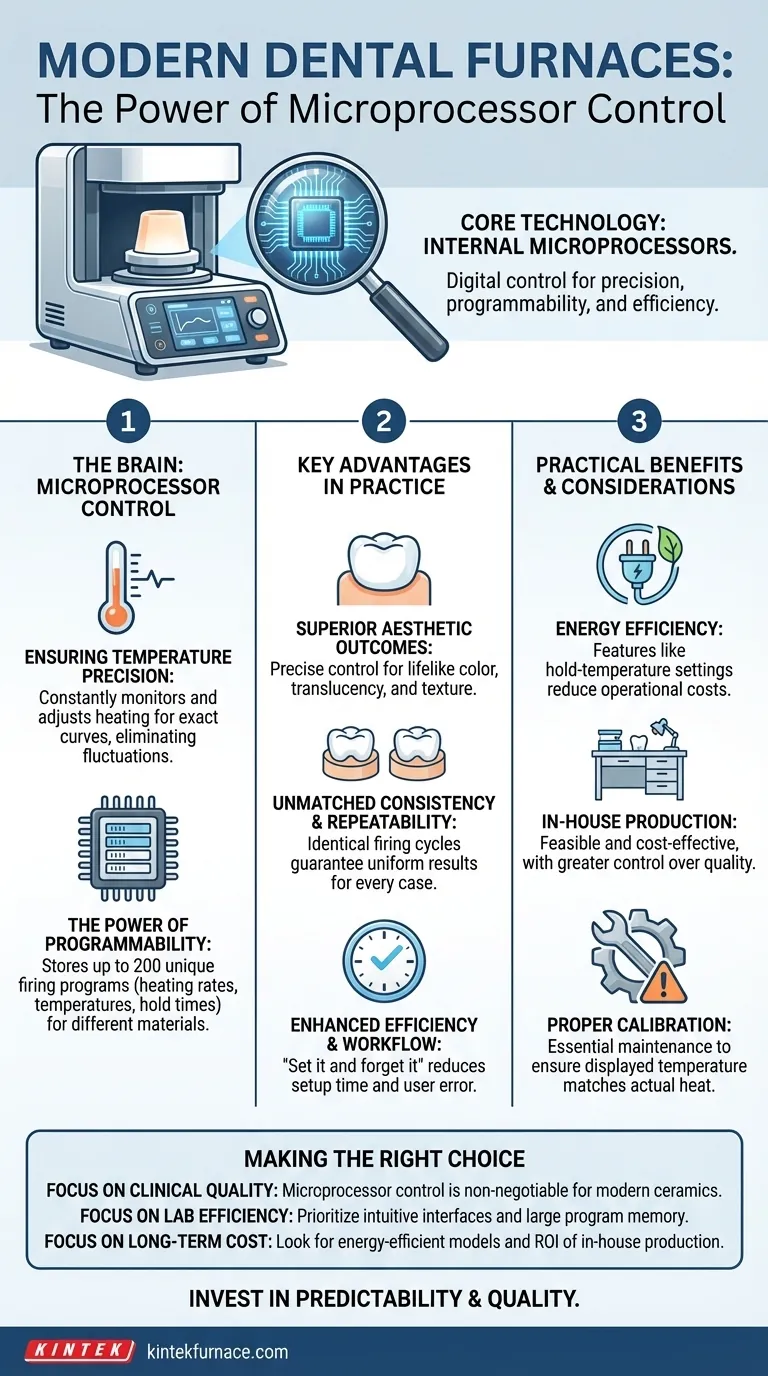

At their core, modern dental furnaces are controlled by internal microprocessors. This digital control is their defining feature, offering significant advantages in precision, programmability, and operational efficiency, which directly translates to higher quality and more consistent dental restorations.

The shift from manual to microprocessor control is not merely a convenience. It is the key technological leap that enables dental professionals to achieve the highly specific and repeatable heating cycles demanded by advanced ceramic materials, ensuring predictable aesthetic and functional outcomes.

The Core Technology: Microprocessor Control

The brain of a modern dental furnace is its microprocessor. Think of it as a small, dedicated computer that governs every aspect of the firing cycle with digital accuracy, a stark contrast to older, manually adjusted or analog systems.

Ensuring Temperature Precision

Microprocessors constantly monitor and adjust the heating elements to follow a pre-set temperature curve exactly. This digital oversight ensures precise temperatures are achieved and held, eliminating the fluctuations common in older furnaces.

This level of precision is critical for modern dental ceramics, where even minor temperature deviations can negatively impact the material's strength, shade, and translucency, compromising the final aesthetic result.

The Power of Programmability

These furnaces feature memory systems capable of storing a large number of firing programs—often up to 200. Each program contains a unique sequence of heating rates, target temperatures, and hold times tailored to a specific ceramic material.

A technician can simply select the correct program for the material being used, ensuring the manufacturer's exact specifications are met every single time. This removes guesswork and standardizes outcomes.

Key Advantages in a Modern Dental Practice

The move to digitally controlled furnaces provides tangible benefits that impact everything from the quality of care to the efficiency of the lab or practice.

Superior Aesthetic Outcomes

The primary advantage is the ability to produce highly aesthetic restorations. By precisely controlling the firing cycle, the furnace ensures the porcelain or ceramic achieves its ideal crystalline structure, resulting in lifelike color, translucency, and surface texture.

Unmatched Consistency and Repeatability

A microprocessor executes a saved program identically every time. This guarantees that a restoration fired today will be indistinguishable from one fired weeks later using the same program and material. This repeatability is essential for multi-unit cases, remakes, and maintaining a high standard of quality.

Enhanced Efficiency and Workflow

The "set it and forget it" nature of programmable furnaces frees up valuable technician time. The simple-to-use digital controls and stored programs drastically reduce setup time and minimize the risk of user error, leading to a more streamlined and productive workflow.

Understanding the Practical Benefits and Considerations

While the technology is powerful, it's important to understand how its features translate to day-to-day operations and what is required to maintain performance.

The Impact of Energy Efficiency

Many modern furnaces include energy-saving features, such as hold-temperature settings that maintain a high heat using only a fraction of the maximum power. Over the lifetime of the unit, this can lead to significant operational cost savings.

Justifying In-House Production

The reliability and user-friendly design of these furnaces make it more feasible for a dental practice to bring crown and bridge fabrication in-house. This can lead to greater control over quality, faster turnaround times, and long-term cost-effectiveness compared to outsourcing all lab work.

The Need for Proper Calibration

A key consideration is that precision instruments require maintenance. To ensure the furnace's displayed temperature matches its actual internal temperature, periodic calibration is essential. Without it, the core benefit of temperature accuracy is lost.

Making the Right Choice for Your Goal

When evaluating a dental furnace, align its features with your primary operational objective.

- If your primary focus is clinical quality and aesthetics: A microprocessor-controlled furnace is non-negotiable for the precise temperature management required by modern ceramic materials.

- If your primary focus is lab efficiency and throughput: Prioritize models with a large program memory and an intuitive digital interface to minimize setup time and reduce the potential for user error.

- If your primary focus is long-term cost management: Look for furnaces with documented energy-efficient modes and consider the ROI of bringing restorations in-house.

Ultimately, investing in a modern, microprocessor-controlled furnace is an investment in the predictability and quality of your final restorations.

Summary Table:

| Feature | Benefit |

|---|---|

| Microprocessor Control | Ensures precise temperature management and repeatable firing cycles |

| Programmability | Allows storage of up to 200 custom programs for various materials |

| Digital Interface | Simplifies operation, reduces setup time, and minimizes user error |

| Energy Efficiency | Lowers operational costs with features like hold-temperature settings |

| Consistency | Guarantees uniform results for multi-unit cases and remakes |

Elevate your dental practice with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering superior quality, efficiency, and cost savings. Contact us today to discuss how we can optimize your dental restoration workflows!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency