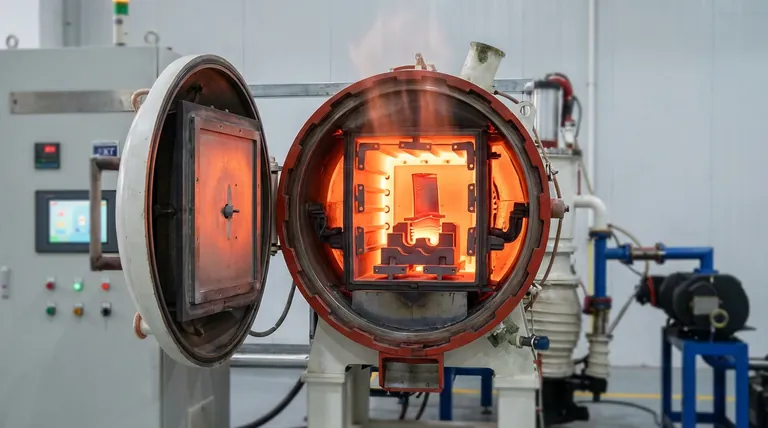

The Moment of Truth

Imagine the quiet hum of a vacuum pump winding down. Hours of processing are complete. A multi-million dollar component—a turbine blade, a medical implant—sits inside, having been subjected to temperatures that would melt steel.

When the door opens, the entire process hinges on one simple question: did the part hold its shape?

For many engineers, the answer is a frustrating "no." The culprit is often not the part itself, but the fixture holding it. Under extreme heat, metal alloys—our intuitive choice for strength—can soften, warp, and fail, compromising the entire run.

This reveals a psychological blind spot. We expect materials to weaken under stress and heat. But in the engineered void of a vacuum furnace, the rules are different. One material thrives.

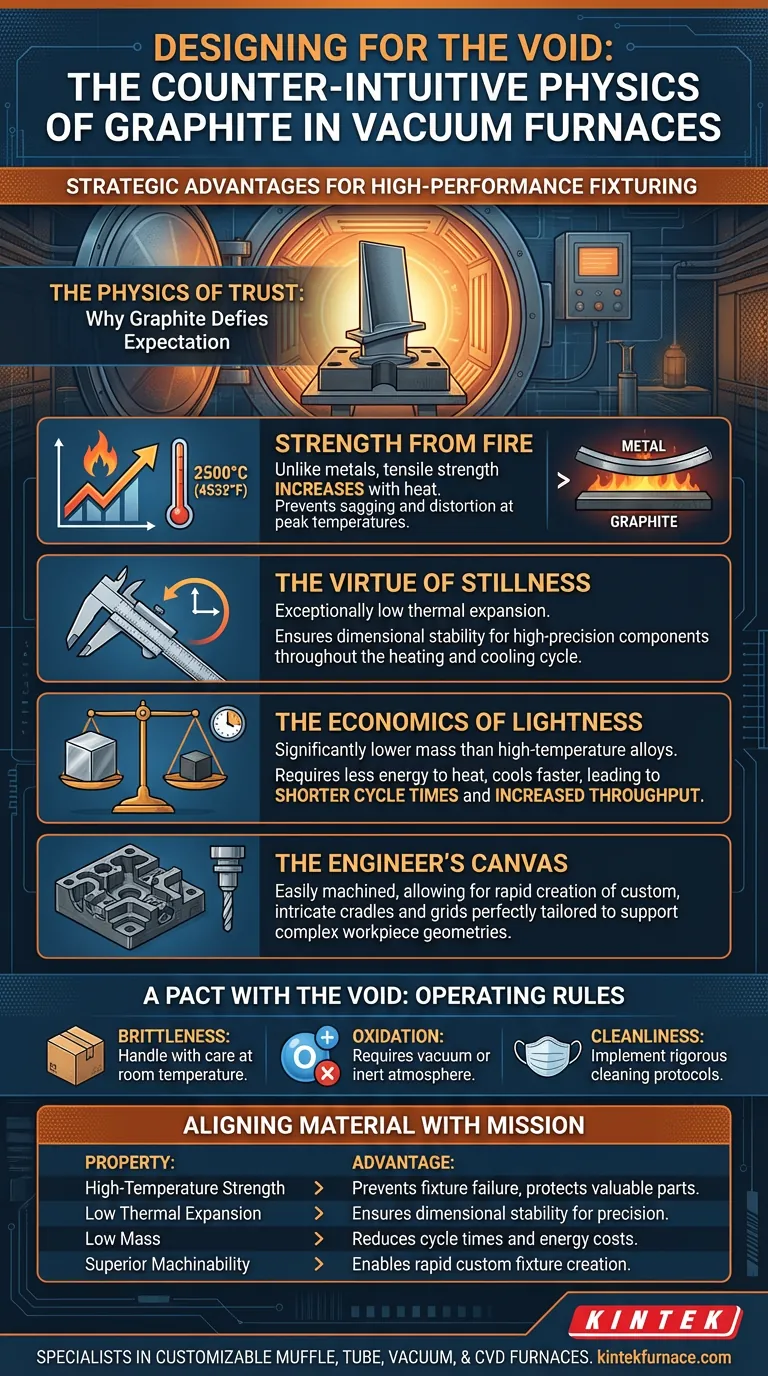

The Physics of Trust: Why Graphite Defies Expectation

Graphite isn't just a good material for high-temperature work; it's a fundamentally different one. Its value comes from a synergy of properties that seem almost purpose-built for the vacuum environment.

Strength from Fire

Unlike metals, which lose their strength as they get hotter, graphite performs a minor miracle. Its tensile strength actually increases with temperature, peaking around 2500°C (4532°F).

Think about that. The fixture holding your critical component is strongest at the most critical moment of the process. It's a guarantee against sagging and distortion when the stakes are highest. This isn't just a material property; it's operational peace of mind.

The Virtue of Stillness

Precision requires stability. Graphite has an exceptionally low coefficient of thermal expansion, meaning it barely grows or shrinks when heated and cooled.

While a metal fixture might expand and induce stress on a part, a graphite fixture remains impassive. It holds the workpiece in the exact intended position from room temperature to peak heat and back again. This stillness is the foundation of repeatable, predictable metallurgical results.

The Economics of Lightness

Graphite is incredibly lightweight compared to high-temperature alloys like molybdenum or Inconel. This isn't a trivial detail; it's a profound economic advantage.

Less mass requires less energy to heat. Less thermal mass means it also cools down faster.

The second-order effect of this is not just lower energy bills. It’s speed. It’s shorter cycle times. It’s increased furnace throughput. It’s the ability to process more parts per day, which is a powerful competitive edge.

The Engineer's Canvas: From Concept to Crucible

Beyond its thermal performance, graphite offers unparalleled design freedom. It is soft and easily machined, a stark contrast to the tough, difficult-to-work superalloys.

This allows engineers to create intricate, custom fixtures perfectly tailored to support complex geometries. You can design delicate cradles that ensure uniform heating for aerospace components or create complex grids for batch processing small parts. Prototyping is fast and cost-effective, turning a design challenge into a simple manufacturing task.

A Pact with the Void: Understanding the Rules

To unlock graphite's incredible advantages, one must respect its limitations. Its strengths are a direct result of the environment it's designed for: a vacuum.

- Brittleness: While a champion when hot, graphite can be brittle at room temperature. It demands careful handling, a small price for its high-temperature heroism.

- Oxidation: In the presence of oxygen at high temperatures, graphite will burn away. Its lifeblood is the vacuum or inert atmosphere of a well-controlled furnace.

- Cleanliness: Machining and handling can create fine dust. In sensitive applications like medical or aerospace, rigorous cleaning protocols are essential to prevent contamination.

These aren't so much weaknesses as they are the operating rules. Follow them, and graphite delivers unmatched performance.

Aligning Material with Mission

Choosing graphite is a strategic decision that optimizes your entire operation. The right fixture, made from the right material, is not an expense—it's an investment in quality and efficiency.

| Property | Strategic Advantage in Vacuum Furnace Operations |

|---|---|

| High-Temperature Strength | Prevents fixture failure at peak temps, protecting valuable parts. |

| Low Thermal Expansion | Ensures dimensional stability for high-precision components. |

| Low Mass | Directly reduces cycle times and energy costs, boosting throughput. |

| Superior Machinability | Enables rapid creation of custom fixtures for complex parts. |

Ultimately, the fixture is only as good as the furnace that creates its environment. A truly optimized process requires a seamless system where the chamber, the controls, and the internal fixturing work in perfect harmony.

At KINTEK, we specialize in creating these complete, high-performance systems. Our expertise in R&D and manufacturing allows us to deliver customizable Muffle, Tube, Vacuum, and CVD furnaces designed to maximize the potential of advanced materials like graphite. We understand that success lies in controlling every variable, from the vacuum level to the precise support of your components.

Let us help you build a more efficient, precise, and reliable thermal processing system. Contact Our Experts

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

Related Articles

- Beyond Heat: How Graphite's Physics Enables Precision in Vacuum Furnaces

- Beyond the Heat: The Psychology of Perfect Vacuum Furnace Operation

- More Than a Void: The Inherent Energy Efficiency of Vacuum Furnace Design

- Strength in the Fire: The Counterintuitive Genius of Graphite in Vacuum Furnaces

- The Unseen Advantage: How Vacuum Furnaces Forge Metallurgical Perfection