You’ve followed the protocol perfectly. The cycle ran for hours, or even days. You open the furnace door, anticipating the perfectly treated component your project depends on, only to find a discolored, warped, or brittle piece of scrap. The entire batch is ruined. Time has been wasted, expensive materials are lost, and your project deadline is now in jeopardy.

If this scenario feels painfully familiar, you are not alone.

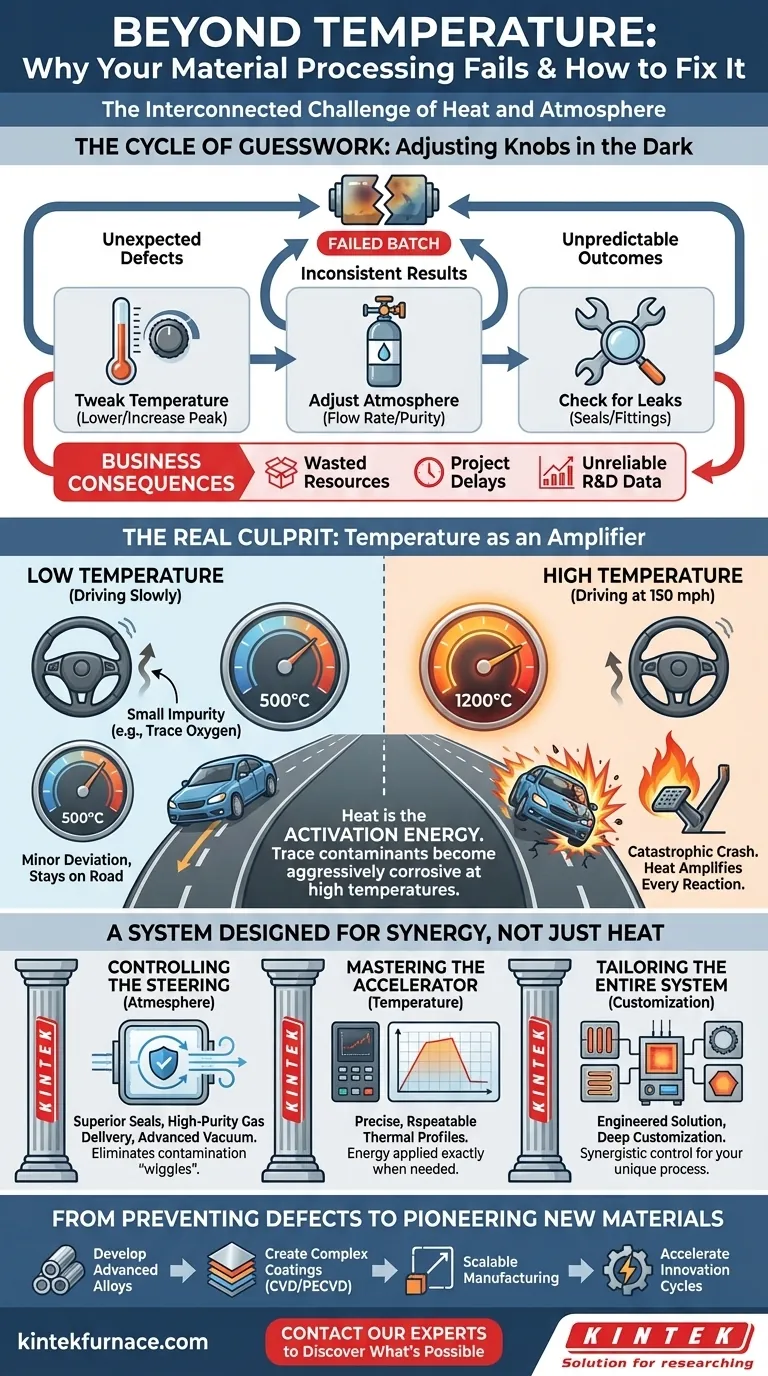

The Cycle of Guesswork: Adjusting Knobs in the Dark

When high-temperature processes go wrong, most researchers and engineers find themselves trapped in a frustrating loop of trial and error. The typical response involves a series of isolated adjustments:

- "Let's tweak the temperature." You lower the peak temperature to prevent warping or increase it to speed up the reaction, only to find a new, unexpected defect appears.

- "Maybe it's the atmosphere." You adjust the gas flow rate or try to improve the purity, but the results remain inconsistent from one batch to the next.

- "It must be a leak." You spend hours checking seals and fittings, and while it sometimes helps, the core problem of unpredictability never truly goes away.

This isn't just an academic challenge; it has severe business consequences. Each failed batch translates directly to wasted resources, project delays that can derail product launches, and unreliable R&D data that undermines confidence in scaling up to production. You're left treating symptoms, unable to diagnose the underlying disease.

The Real Culprit: Temperature as an Amplifier

The reason these isolated fixes fail is a fundamental misunderstanding of the physics at play. We tend to think of temperature and atmosphere as two separate controls. In reality, they are a deeply interconnected system, where one dramatically multiplies the effect of the other.

Think of it this way: the furnace atmosphere is the steering wheel, and the temperature is the gas pedal.

At a low temperature (driving slowly), a small impurity in your atmosphere—a tiny oxygen or moisture leak—is like a slight wiggle of the steering wheel. It's a minor deviation, and the car stays on the road.

But at high temperatures (driving at 150 mph), that exact same tiny wiggle can send you careening into a catastrophic crash.

Heat acts as a powerful amplifier for every chemical reaction, both good and bad. It provides the activation energy that makes things happen, fast. A trace contaminant that is harmless at 500°C can become aggressively corrosive at 1200°C. This is why simply adjusting the "heat" or the "atmosphere" independently doesn't work. You are ignoring the explosive interaction between them. The real key is to achieve absolute control over both, simultaneously.

A System Designed for Synergy, Not Just Heat

To tame this powerful interaction, you need more than just a box that gets hot. You need an integrated process environment engineered to manage the interplay between heat and atmosphere with absolute precision. This is not an afterthought; it is the core design philosophy behind KINTEK’s furnace solutions.

Our systems are built from the ground up to address the root cause of inconsistency:

- Controlling the "Steering": An inert or reactive atmosphere is only as good as its purity. Our Vacuum & Atmosphere Furnaces are engineered with superior seals, high-purity gas delivery systems, and advanced vacuum technology to ensure the environment inside the chamber is exactly what you designed it to be, eliminating the "wiggles" caused by contamination.

- Mastering the "Accelerator": Our advanced controllers do more than just hit a setpoint. They allow for precise, repeatable thermal profiles, ensuring the energy is applied exactly when and how it's needed, working in perfect concert with the controlled atmosphere.

- Tailoring the Entire System: Every material and process has a unique "sweet spot" in the temperature-atmosphere relationship. Our deep customization capability means we don't just sell you a furnace; we engineer a solution. From the chamber geometry and heating elements to the specific gas mixing and vacuum configuration, we build a system that gives you synergistic control over your unique process.

A KINTEK furnace isn't just a tool; it's the embodiment of a solution, designed with a deep understanding of the core scientific challenge you face.

From Preventing Defects to Pioneering New Materials

When you finally gain precise, repeatable control over the heat-atmosphere interaction, something remarkable happens. Your focus shifts from simply trying to avoid failure to actively unlocking new possibilities.

The conversation changes from "Why did this batch fail?" to "What can we create next?"

- You can develop advanced alloys that require purity levels previously unattainable.

- You can create complex, multi-layered functional coatings with our CVD/PECVD systems, where process synchronization is everything.

- You can move from uncertain R&D to a scalable, reliable manufacturing process with confidence.

- You can accelerate your innovation cycles from months to weeks, because your results are no longer a matter of chance, but of design.

Solving this persistent technical problem is the first step toward achieving larger business goals: faster innovation, higher product quality, and a significant competitive advantage. If you're ready to move beyond guesswork and achieve true mastery over your material processing, our team has the expertise to help you build the right solution for your unique application. Contact Our Experts to discuss your project and discover what's possible.

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

Related Articles

- Mastering the Void: How Tube Furnaces Engineer Predictable Outcomes

- Beyond Heat: The Physics of Control in a Tube Furnace

- Clarity Under Fire: The Psychological Case for Quartz Tube Furnaces

- The Controlled Universe: Why Tube Furnaces Prioritize Precision Over Scale

- Mastering the Micro-Environment: The Art and Science of the Laboratory Tube Furnace