Precise thermal regulation is critical because overheating ductile iron in a rotary furnace causes rapid degradation of the refractory lining and compromises the metallurgical quality of the melt. Although these furnaces possess high thermal capabilities, strict measurement ensures you hit exact tapping targets without crossing dangerous operational thresholds.

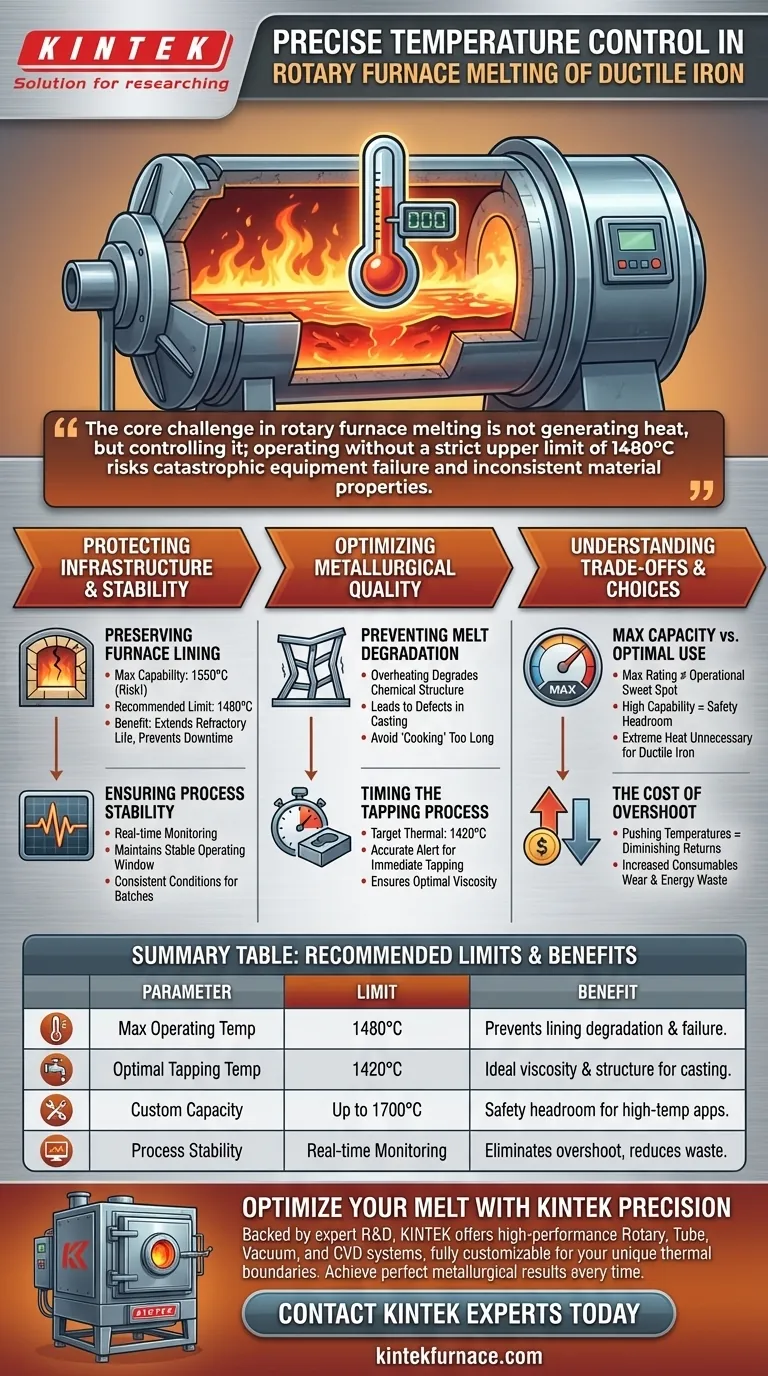

The core challenge in rotary furnace melting is not generating heat, but controlling it; operating without a strict upper limit of 1480°C risks catastrophic equipment failure and inconsistent material properties.

Protecting Infrastructure and Stability

Preserving the Furnace Lining

Rotary furnaces are technically capable of reaching temperatures as high as 1550°C. However, operating at this maximum capacity is detrimental to the equipment.

A strict upper limit of 1480°C is generally recommended. Adhering to this limit significantly extends the lifespan of the furnace’s refractory lining, which prevents costly downtime for repairs.

Ensuring Process Stability

Exceeding recommended temperature limits creates an unstable melting environment. This instability makes it difficult to maintain consistent conditions for subsequent batches.

Precise measurement tools allow operators to monitor thermal accumulation in real-time. This ensures the furnace remains within a stable operating window throughout the melt cycle.

Optimizing Metallurgical Quality

Preventing Melt Degradation

Iron quality is highly sensitive to overheating. If the temperature surpasses the operational limit, the chemical structure of the melt can degrade.

This degradation often leads to defects in the final casting. Precise control prevents the melt from "cooking" too long at excessive temperatures.

Timing the Tapping Process

The transition to downstream processes relies on hitting a specific thermal target, often 1420°C.

Accurate instrumentation alerts operators the moment this target is reached. This allows for immediate tapping, ensuring the iron enters the mold at the optimal viscosity and temperature.

Understanding the Trade-offs

Maximum Capacity vs. Optimal Use

It is a common pitfall to confuse a furnace's maximum rating with its operational sweet spot.

While some advanced rotary tube furnaces can be customized for work up to 1700°C, applying this extreme heat to standard ductile iron melting is unnecessary and hazardous. High capability provides headroom for safety, not a target for daily operation.

The Cost of Overshoot

Pushing temperatures higher to "speed up" melting often results in diminishing returns. The minor gain in melting speed is usually negated by the increased wear on consumables and energy waste.

Making the Right Choice for Your Goal

To maximize the efficiency of your rotary furnace operations, align your temperature controls with your specific production priorities:

- If your primary focus is Equipment Longevity: Enforce a strict hard cap at 1480°C to maximize the service life of your refractory lining.

- If your primary focus is Product Consistency: Prioritize the accuracy of your 1420°C tapping sensors to ensure every pour happens at the exact same thermal state.

True process control comes from disciplined adherence to these thermal boundaries.

Summary Table:

| Operational Parameter | Recommended Limit | Benefit of Control |

|---|---|---|

| Max Operating Temp | 1480°C | Prevents refractory lining degradation and equipment failure. |

| Optimal Tapping Temp | 1420°C | Ensures ideal viscosity and metallurgical structure for casting. |

| Custom Capacity | Up to 1700°C | Provides safety headroom for specialized high-temp applications. |

| Process Stability | Real-time monitoring | Eliminates thermal overshoot and reduces energy waste. |

Optimize Your Melt with KINTEK Precision

Don't let uncontrolled heat compromise your output or destroy your equipment. Backed by expert R&D and manufacturing, KINTEK offers high-performance Rotary, Tube, Vacuum, and CVD systems designed for the most demanding lab and industrial environments. Our furnaces are fully customizable to meet your unique thermal boundaries, ensuring you achieve perfect metallurgical results every time.

Ready to enhance your lab's efficiency and equipment longevity?

Visual Guide

References

- Jan Bredl. Quality Prediction of Spheroidal Graphite Cast Iron for Machine Tool Parts. DOI: 10.21062/mft.2025.032

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What factors should be considered when choosing between a batch-type and continuous-type rotary kiln? Optimize Your Production Strategy

- How does customization benefit the use of rotary kilns? Boost Efficiency and Quality with Tailored Solutions

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- How does the design and operation of a carbonization furnace influence biomass fuel production? High-Efficiency Sludge Conversion

- What types of feedstock can rotary kilns handle? Versatile Processing for Powders, Wastes, and More

- What distinguishes rotary furnaces from vacuum furnaces? Choose the Right Furnace for Your Process

- What are the disadvantages of rotary kiln lime kilns in terms of construction and operation? High Costs, Complex Operation

- What processes can rotary tube furnaces be used for? Achieve Uniform Thermal Processing for Your Materials