Choosing the right rotary kiln is a foundational decision that directly impacts your operational efficiency, flexibility, and overall production costs. The choice between a batch and continuous system primarily hinges on your required production volume, the variety of materials you need to process, and your long-term operational strategy. Batch kilns are designed for flexibility with smaller, varied runs, while continuous kilns are built for high-throughput, dedicated production of a single material.

The decision between a batch and continuous kiln is less about the hardware itself and more about defining your operational model. Batch kilns offer flexibility for research and diverse, low-volume products, while continuous kilns prioritize efficiency and throughput for large-scale, dedicated production lines.

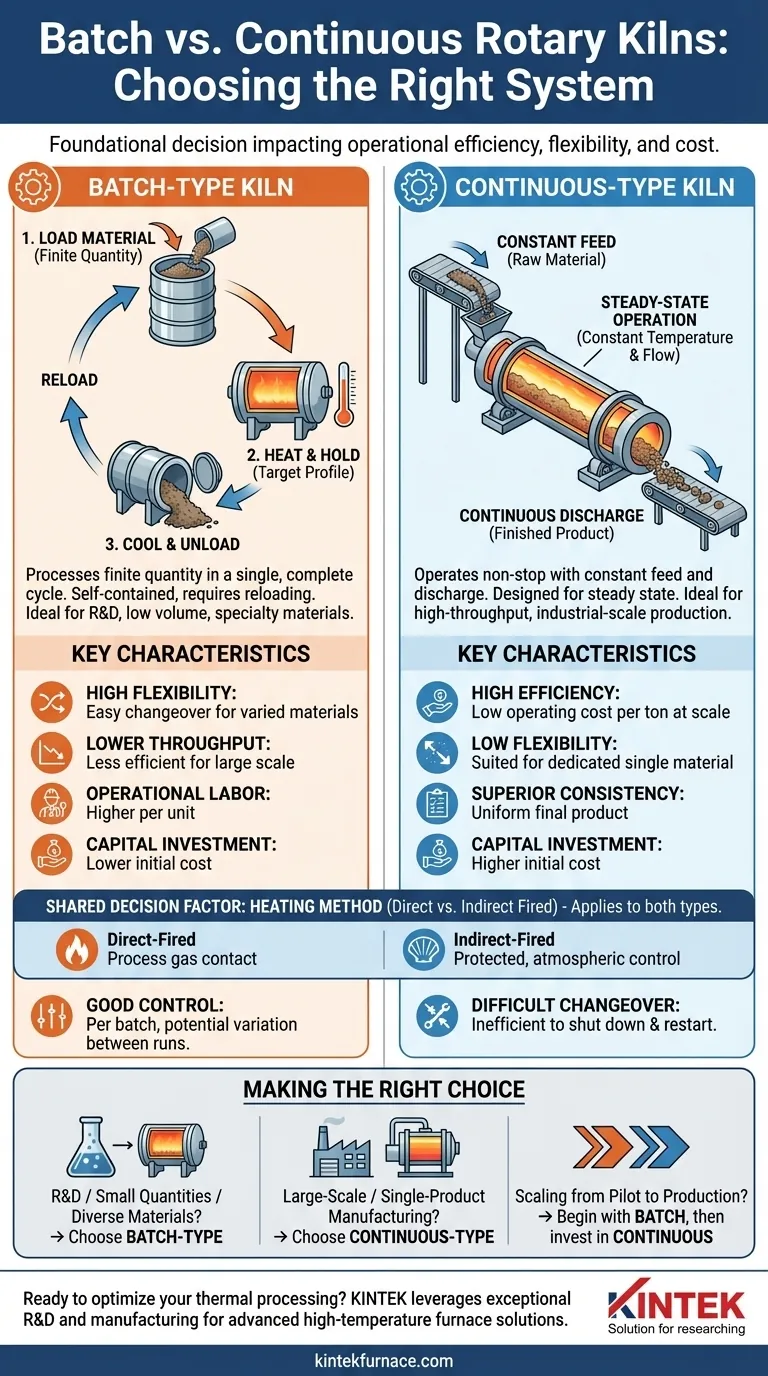

Core Operational Differences: Batch vs. Continuous

Understanding the fundamental workflow of each kiln type is the first step in making an informed decision. Their operating principles are designed for entirely different goals.

The Batch Processing Cycle

A batch-type kiln processes a finite, measured quantity of material in a single, complete cycle. This involves loading the material, heating it to the target temperature profile, holding it for the required residence time, and then cooling and unloading the entire batch.

These systems are self-contained and require reloading between each run. They are typically smaller, with processing volumes ranging from a few hundred milliliters for lab-scale units to a few thousand for pilot-scale production.

The Continuous Processing Flow

A continuous-type kiln operates non-stop, with raw material constantly fed into one end and finished product continuously discharged from the other. The system is designed to reach a steady state where temperature and material flow are constant.

The total processing capacity is determined by the feed rate and the physical size of the kiln. Run times are limited only by the capacity of the feed and collection hoppers, which can range from a few liters to several hundred, enabling uninterrupted industrial-scale production.

Key Decision Factors Analyzed

Beyond the basic operating cycle, several critical factors must be weighed to align the kiln's capabilities with your business and production needs.

Production Volume and Scale

This is the most significant factor. Batch kilns are ideal for research and development, process testing, and the production of high-value, low-volume specialty materials.

Continuous kilns are the standard for bulk processing. They are used in industries like cement, minerals, and waste treatment where massive throughput is necessary to be economical.

Material Variety and Changeover

If your process involves running many different materials or frequent changes in processing parameters, a batch kiln is far more suitable. The system can be easily cleaned and reset between runs.

A continuous kiln is extremely inefficient to shut down, clean, and restart. It is best suited for a dedicated production line running the same material for extended periods.

Process Consistency and Quality Control

Once a continuous kiln reaches its steady state, it offers superior process consistency. Every particle of material is exposed to a nearly identical time-temperature profile, resulting in a highly uniform final product.

While batch kilns provide excellent control over a single run, there can be minor variations from one batch to the next, requiring strict procedural controls to ensure product consistency.

A Note on Heating Method

The choice between direct-fired and indirect-fired (calciner) heating is separate from the batch vs. continuous decision, but equally critical. This choice applies to both kiln types.

A direct-fired kiln allows process gases to come into direct contact with the material, which is efficient but can be undesirable if the material is sensitive to the atmosphere. An indirect-fired kiln heats the material through the shell wall, protecting it from combustion gases and allowing for precise atmospheric control.

Understanding the Trade-offs

No single solution is perfect. Objectively evaluating the inherent compromises of each system is critical for avoiding costly mistakes.

The Flexibility of Batch Kilns

The primary advantage of a batch kiln is its flexibility. It is ideal for exploring new processes and producing a portfolio of different products.

However, this comes at the cost of lower throughput and higher operational labor per unit of product. The cycle of heating, cooling, and reloading makes it inefficient for large-scale production.

The Efficiency of Continuous Kilns

A continuous kiln offers unparalleled efficiency and low operating cost per ton at scale. Its consistent operation makes it perfect for commodity production.

The major trade-off is its inflexibility. These systems represent a significant capital investment and are locked into a specific process and material. They require a large, stable supply of feedstock to run economically.

Making the Right Choice for Your Goal

Your final decision should be a direct reflection of your primary objective.

- If your primary focus is R&D or producing small quantities of diverse materials: A batch-type kiln offers the necessary flexibility and lower initial capital investment.

- If your primary focus is large-scale, single-product manufacturing: A continuous-type kiln is the only viable path to achieving the high throughput and low per-unit costs required.

- If your primary focus is scaling from a pilot phase to full production: Begin with a batch kiln to validate your process and then use that data to design and invest in a continuous kiln once the market is proven.

By aligning your kiln choice with your core operational strategy, you ensure your thermal process is efficient, scalable, and built for success.

Summary Table:

| Factor | Batch-Type Kiln | Continuous-Type Kiln |

|---|---|---|

| Production Volume | Ideal for low-volume, R&D, and pilot-scale | Best for high-throughput, industrial-scale |

| Material Variety | High flexibility; easy changeover between runs | Low flexibility; suited for dedicated, single-material processing |

| Process Consistency | Good control per batch, but potential run-to-run variations | Superior consistency with steady-state operation |

| Operational Efficiency | Lower throughput; higher labor per unit | High efficiency; low operating cost per ton at scale |

| Capital Investment | Lower initial cost | Higher initial investment |

Ready to optimize your thermal processing with the right rotary kiln? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production requirements. Whether you're in R&D, pilot-scale testing, or full-scale manufacturing, we can help you achieve superior efficiency and consistency. Contact us today to discuss how our solutions can benefit your laboratory or production facility!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- What advantages do electrically heated rotary kilns offer in temperature control? Achieve Precision and Uniformity for Superior Results

- What is the basic working principle of a rotary kiln? Master Industrial Thermal Processing Efficiency

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource

- What are the main components in the construction of a rotary kiln? A Guide to the Core Systems

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency