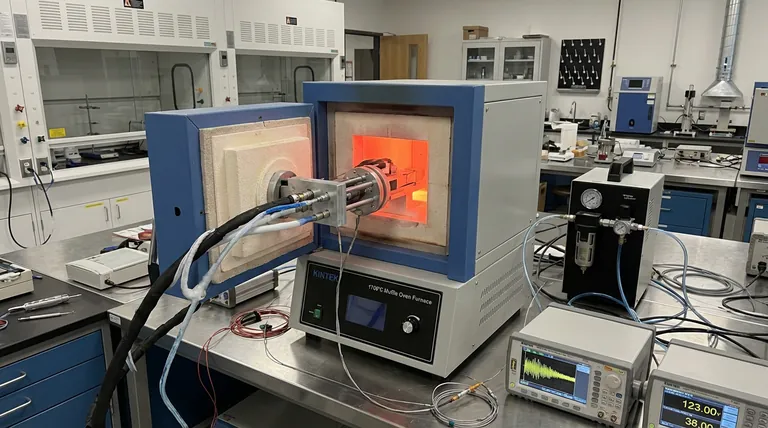

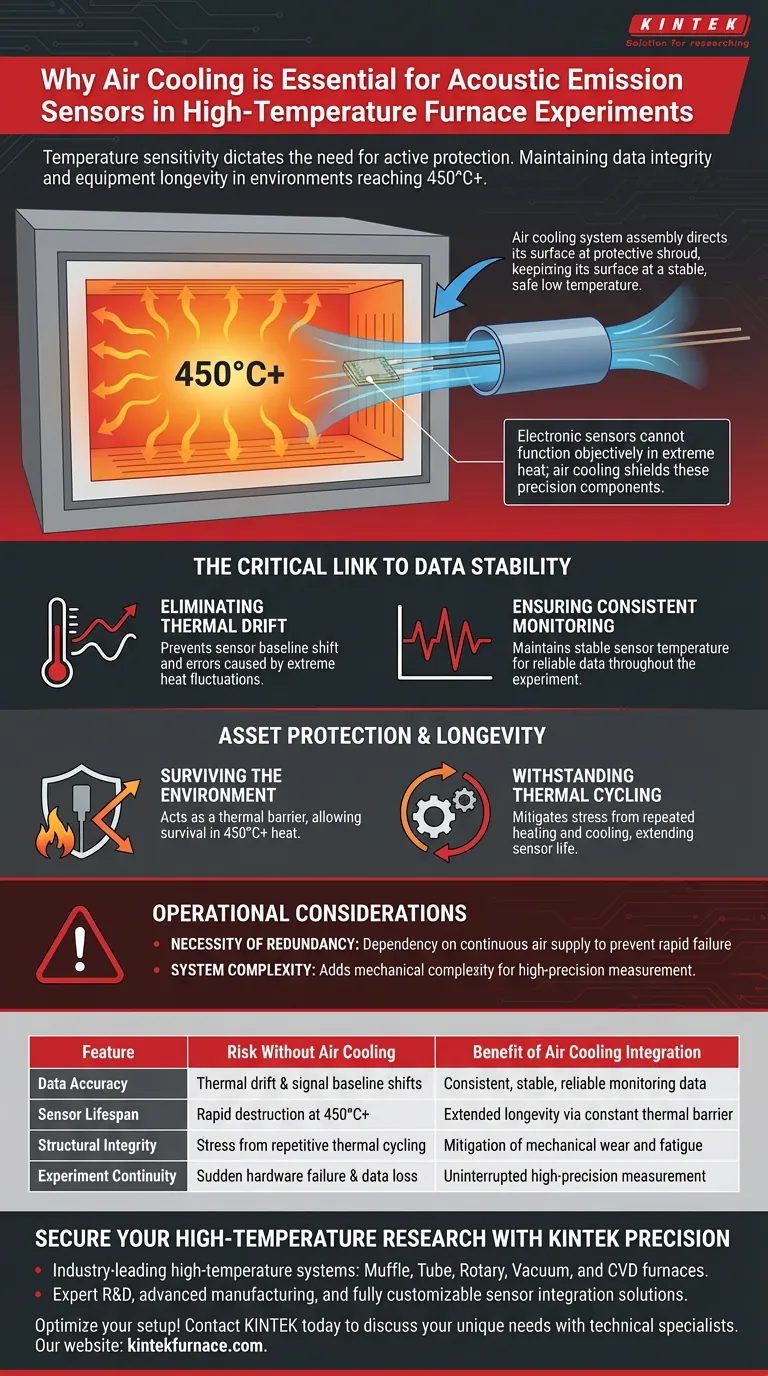

Temperature sensitivity dictates the need for active protection. High-temperature furnace experiments often reach internal temperatures of 450°C or higher, an environment inherently hostile to precision electronics. An integrated air cooling system is essential to maintain acoustic emission sensors and load cells within a safe, low-temperature range, preventing hardware failure and ensuring the validity of your monitoring data.

Electronic sensors cannot function objectively in extreme heat; air cooling shields these precision components to ensure that the data you collect reflects the experiment, not the thermal degradation of your equipment.

The Critical Link to Data Stability

Eliminating Thermal Drift

Acoustic emission sensors and load cells are highly sensitive to temperature changes. Without regulation, extreme heat causes the sensor's baseline to shift, introducing errors known as thermal drift.

Ensuring Consistent Monitoring

Air cooling maintains the sensors at a stable, low temperature regardless of the furnace's internal heat. This stability ensures that the monitoring data remains consistent and reliable throughout the entire experiment.

Asset Protection and Longevity

Surviving the Environment

Furnace interiors exceeding 450°C will rapidly destroy standard electronic components. The cooling system acts as a thermal barrier, allowing delicate sensors to physically survive close proximity to these high temperatures.

Withstanding Thermal Cycling

Long-term experiments involve repeated heating and cooling phases, known as thermal cycling. This process places immense stress on materials.

Active air cooling mitigates this stress. By keeping the sensor temperature constant, it protects the component from the wear and tear of cycling, significantly extending the longevity of the sensors.

Operational Considerations

The Necessity of Redundancy

While air cooling solves the temperature problem, it introduces a dependency on the air supply. If the cooling airflow is interrupted, sensor failure can occur rapidly.

System Complexity

Integrating a cooling system adds a layer of mechanical complexity to the sensor assembly. However, this is a necessary trade-off to enable high-precision measurement in a high-temperature environment.

Ensuring Successful High-Temperature Monitoring

To maximize the effectiveness of your sensor assembly, consider your specific goals:

- If your primary focus is Data Integrity: Prioritize a cooling system that maintains a constant temperature to eliminate thermal drift and ensure the stability of monitoring data.

- If your primary focus is Equipment Longevity: Ensure the air cooling flow is continuous and sufficient to counteract the peak 450°C furnace temperature during long-term thermal cycling.

Invest in robust cooling today to prevent costly sensor replacement and compromised data tomorrow.

Summary Table:

| Feature | Risk Without Air Cooling | Benefit of Air Cooling Integration |

|---|---|---|

| Data Accuracy | Thermal drift and signal baseline shifts | Consistent, stable, and reliable monitoring data |

| Sensor Lifespan | Rapid destruction of electronics at 450°C+ | Extended longevity via constant thermal barrier |

| Structural Integrity | Stress from repetitive thermal cycling | Mitigation of mechanical wear and fatigue |

| Experiment Continuity | Sudden hardware failure and data loss | Uninterrupted high-precision measurement |

Secure Your High-Temperature Research with KINTEK Precision

Don't let extreme heat compromise your critical data or destroy expensive equipment. KINTEK provides industry-leading laboratory high-temperature systems—including Muffle, Tube, Rotary, Vacuum, and CVD furnaces—specifically designed to handle the most demanding thermal environments.

Backed by expert R&D and advanced manufacturing, our systems are fully customizable to accommodate your specific sensor integration and air-cooling requirements. Ensure your sensors survive the heat and deliver the precision your work demands.

Ready to optimize your high-temperature experimental setup? Contact KINTEK today to discuss your unique needs with our technical specialists.

Visual Guide

References

- Luke Griffiths, H. Albert Gilg. Thermal Stressing of Volcanic Rock: Microcracking and Crack Closure Monitored Through Acoustic Emission, Ultrasonic Velocity, and Thermal Expansion. DOI: 10.1029/2023jb027766

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What are the three essential components needed to produce graphite heating elements? The Key to Reliable High-Temp Performance

- Why are corrosion-resistant steel crucibles required for biochar production? Ensure Purity & Thermal Integrity

- Why are both external and internal thermocouples required for pyrolysis? Optimize Your Thermal Reaction Monitoring

- How can the service life of silicon carbide heating elements be prolonged? Extend Lifespan with Expert Tips

- What are the main advantages of MoSi2 heating elements? Unlock High-Temp Efficiency and Longevity

- Why is thermal strain simulation analysis essential? Ensure Maximum Reliability in Industrial Radiant Tubes

- How is infrared energy directed in a quartz heater? Uncover the Science Behind Efficient, Targeted Warmth

- Why are silicon carbide heating elements suitable for high-temperature applications? Discover Their Key Benefits