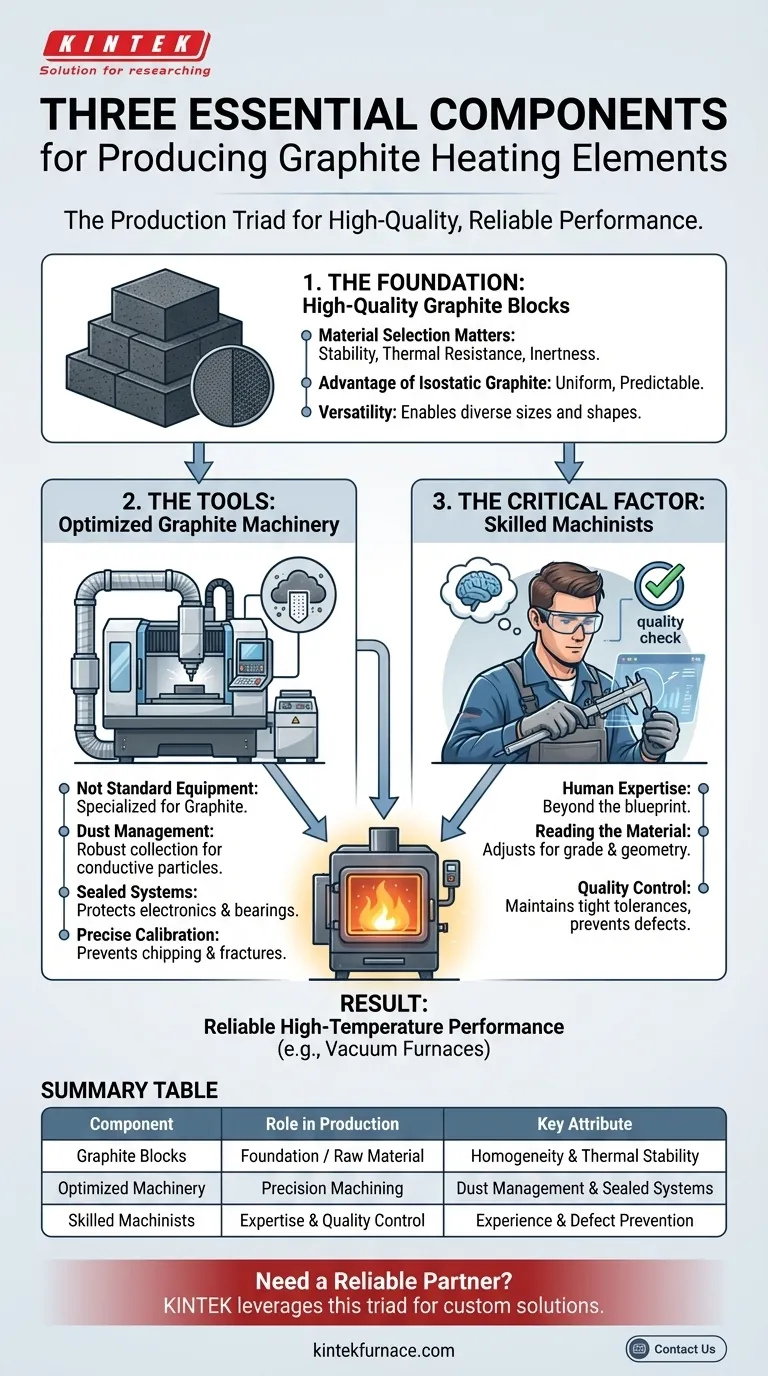

To produce high-quality graphite heating elements, you need three essential components working in concert: a supply of appropriate graphite blocks, machinery specifically optimized for graphite, and the expertise of skilled machinists. These elements form a production triad where the quality of the final product is limited by the weakest link in the chain.

The creation of a reliable graphite heating element is not merely a manufacturing task; it is a specialized craft that balances the intrinsic properties of the raw material with the precision of optimized tools and the irreplaceable judgment of human experience.

The Foundation: High-Quality Graphite Blocks

The entire process begins with the raw material. The grade and quality of the graphite block directly determine the performance and lifespan of the final heating element.

Why Material Selection Matters

Graphite is chosen for its remarkable stability at high temperatures, resistance to thermal shock, and chemical inertness. However, different grades of graphite possess these properties to varying degrees. Selecting the right block is the first and most critical step in ensuring the element will survive the extreme conditions inside a high-temperature furnace.

The Advantage of Isostatic Graphite

Many high-performance elements are made from isostatic graphite. This material is formed under high pressure from all directions, giving it homogeneous properties. This uniformity ensures even heating across the element and makes the machining process more predictable, reducing the risk of defects.

Versatility in Size and Shape

Using large graphite blocks as the starting point provides immense design flexibility. Elements can be machined into nearly any conceivable size or shape, from massive components for large industrial furnaces to smaller, more intricate designs for specialized applications.

The Tools: Optimized Graphite Machinery

Graphite cannot be machined effectively or safely with standard metalworking equipment. The process requires machines specifically designed or modified to handle graphite's unique characteristics.

Why Standard Machines Fall Short

Machining graphite creates a fine, abrasive, and highly conductive dust. In a standard machine, this dust can infiltrate electronic components, causing short circuits and catastrophic failure. Its abrasive nature also causes premature wear on machine components not designed to withstand it.

Key Machine Optimizations

Machines optimized for graphite feature robust dust collection and filtration systems to manage the conductive particles. They also utilize sealed electronics and bearings to prevent contamination. The tooling, speeds, and feeds are all calibrated specifically for cutting graphite without causing chipping or fractures.

The Critical Factor: Skilled Machinists

The final essential component is human expertise. A skilled machinist brings an understanding that machinery alone cannot replicate, turning a simple block into a precision component.

Beyond Following a Blueprint

An experienced graphite machinist understands the nuances of the material. They can "read" the graphite as they work, adjusting their approach based on the specific grade and the part's geometry to prevent defects.

The Human Touch in Quality Control

These specialists know how to maintain the extremely tight tolerances required for heating elements to function correctly. Their expertise is the final line of defense against imperfections that could lead to hot spots, uneven heating, or premature failure of the element in a live production environment.

Understanding the Application Context

These three components are critical because of the demanding industries that rely on graphite heating elements. Their reliability is not a luxury; it is a necessity for continuous manufacturing operations.

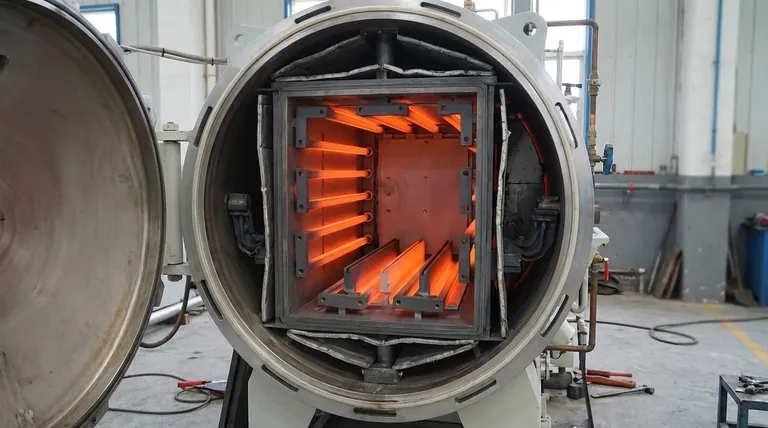

High-Temperature Vacuum Furnaces

The most common application is in high-temperature vacuum furnaces. These environments are unforgiving, and the heating elements are central to processes like sintering metals, producing advanced ceramics, or brazing copper components.

The Value of Longevity

A well-made graphite heating element has a long operational lifespan. This is a direct result of using the correct raw material, machining it with precision on the right equipment, and leveraging the skill of an expert machinist. The result is less furnace downtime and lower operational costs.

Making the Right Choice for Your Goal

Understanding this production triad is key to sourcing or creating reliable heating elements. Your approach should depend on your primary objective.

- If your primary focus is sourcing finished elements: Prioritize suppliers who can prove their expertise in material selection, show you their specialized graphite machining facilities, and have a team of experienced machinists.

- If your primary focus is in-house production: Recognize that investing in optimized machinery and skilled personnel is as critical as sourcing high-grade graphite blocks.

- If your primary focus is engineering and design: Collaborate directly with experienced graphite machinists to ensure your designs are not only functional but also manufacturable and cost-effective.

Ultimately, mastering the interplay between material, machinery, and machinist is the definitive path to achieving reliable high-temperature performance.

Summary Table:

| Component | Role in Production | Key Attribute |

|---|---|---|

| High-Quality Graphite Blocks | Foundation / Raw Material | Homogeneity & Thermal Stability |

| Optimized Graphite Machinery | Precision Machining | Dust Management & Sealed Systems |

| Skilled Machinists | Expertise & Quality Control | Experience & Defect Prevention |

Need a reliable partner for your high-temperature furnace components? At KINTEK, we leverage our exceptional R&D and in-house manufacturing capabilities to provide advanced, custom graphite heating elements and furnace solutions. Our product line, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is backed by deep customization to meet your unique experimental and production requirements. Contact us today to discuss how our expertise can enhance your lab's efficiency and performance!

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is graphite cost-effective for vacuum furnaces? Maximize Long-Term ROI & Efficiency

- Why are graphite fixtures and holders important in vacuum furnaces? Unlock Precision & Durability

- What is the mechanism and effect of post-annealing NiTi thin films in a vacuum furnace? Unlock Superelasticity

- What is the primary function of a vacuum graphite furnace? Achieve Extreme-Temperature Material Purity

- Why are vacuum furnaces used for the re-quenching of samples after a boriding treatment? Master Core Toughness