Corrosion-resistant steel crucibles are essential because laboratory-scale pyrolysis involves a combination of extreme heat and aggressive chemical environments. These specialized vessels prevent material degradation—such as peeling or flaking—that would otherwise contaminate the resulting biochar with metallic impurities. By maintaining their structural integrity at temperatures between 500°C and 700°C, they ensure both sample purity and consistent thermal distribution during the conversion process.

Core Takeaway: Choosing corrosion-resistant steel is a critical measure to protect the chemical purity of biochar from the corrosive gases and thermal stress inherent in high-temperature biomass processing.

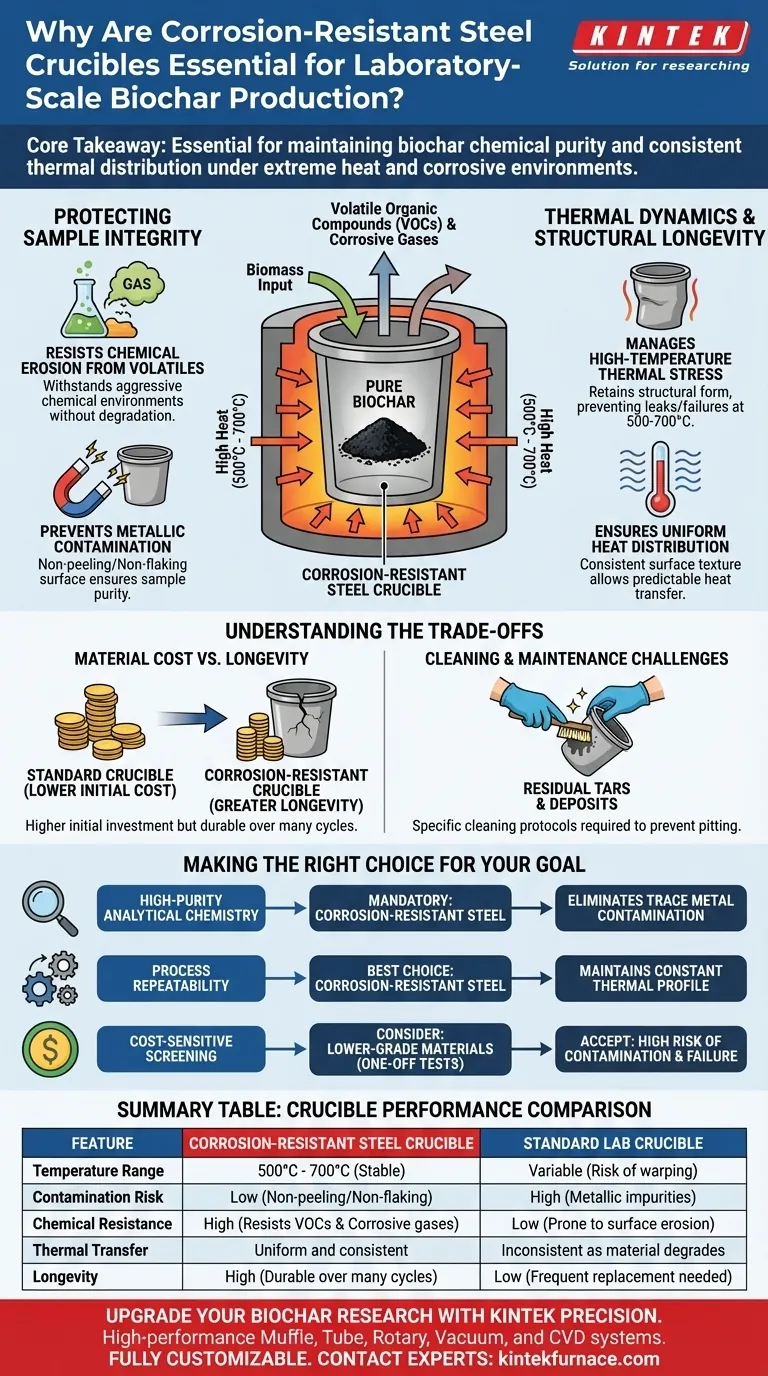

Protecting Sample Integrity under Extreme Conditions

Resisting Chemical Erosion from Volatiles

During the pyrolysis of biomass digestate, the material releases a complex mixture of volatile organic compounds (VOCs) and corrosive gases.

Standard containers often react with these byproducts, leading to surface degradation. Corrosion-resistant steel is specifically engineered to withstand this chemical erosion without breaking down.

Preventing Metallic Contamination

If a crucible begins to peel or flake under stress, microscopic metal particles can integrate into the biochar.

Maintaining a closed pyrolysis environment free from these impurities is vital for accurate laboratory analysis. Corrosion-resistant materials ensure that the final biochar profile reflects the biomass source rather than the container.

Thermal Dynamics and Structural Longevity

Managing High-Temperature Thermal Stress

Pyrolysis typically occurs at temperatures ranging from 500°C to 700°C, which subjects the crucible to significant thermal stress.

Lower-grade materials may warp or become brittle after repeated heating cycles. Specialized steel retains its structural form, preventing leaks or mechanical failures during sensitive experiments.

Ensuring Uniform Heat Distribution

The efficiency of biochar production depends on uniform heating throughout the sample.

Corrosion-resistant crucibles maintain a consistent surface texture and thickness over time. This consistency allows for predictable heat transfer, ensuring the biomass reaches the required temperatures evenly.

Understanding the Trade-offs

Material Cost vs. Longevity

While corrosion-resistant steel crucibles require a higher initial investment than standard carbon steel or ceramic alternatives, they offer greater longevity.

Frequent replacement of degraded crucibles can lead to higher long-term costs and potential downtime in the lab.

Cleaning and Maintenance Challenges

Despite their resistance, these crucibles still require specific cleaning protocols to remove residual tars and carbon deposits.

Failure to clean them properly can lead to localized pitting over time, which may eventually compromise the "non-peeling" benefits of the steel.

Making the Right Choice for Your Goal

When selecting equipment for laboratory-scale biochar production, your material choice should align with your specific research parameters:

- If your primary focus is high-purity analytical chemistry: Corrosion-resistant steel is mandatory to eliminate the risk of trace metal contamination in your biochar samples.

- If your primary focus is process repeatability: These crucibles are the best choice because they maintain a constant thermal profile across dozens of heating cycles.

- If your primary focus is cost-sensitive screening: You may consider lower-grade materials for one-off tests, but you must accept the high risk of sample contamination and crucible failure.

Proper crucible selection is the foundation of reliable, uncontaminated biochar research in any high-temperature environment.

Summary Table:

| Feature | Corrosion-Resistant Steel Crucible | Standard Lab Crucible |

|---|---|---|

| Temperature Range | 500°C - 700°C (Stable) | Variable (Risk of warping) |

| Contamination Risk | Low (Non-peeling/Non-flaking) | High (Metallic impurities) |

| Chemical Resistance | High (Resists VOCs & corrosive gases) | Low (Prone to surface erosion) |

| Thermal Transfer | Uniform and consistent | Inconsistent as material degrades |

| Longevity | High (Durable over many cycles) | Low (Frequent replacement needed) |

Upgrade Your Biochar Research with KINTEK Precision

Don't let crucible degradation compromise your laboratory results. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnace accessories. Whether you are processing biomass or engineering advanced materials, our systems are fully customizable to meet your unique temperature and purity requirements.

Ready to ensure consistent, contamination-free results? Contact our technical experts today to find the perfect thermal solution for your laboratory.

Visual Guide

References

- Van Ngoc Duong, Hynek Roubík. A novel treatment of biogas digestate waste for biochar production and its adsorption of methylene blue and malachite green in a binary system. DOI: 10.1002/bbb.2772

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

People Also Ask

- How does an electric heating system ensure stable ignition during coal gasification? Achieving Reliable Process Control

- Why are MoSi2 heating elements considered fragile? Understanding Brittleness & Chemical Vulnerability

- What materials are commonly used in heating elements? Discover the Best Options for Your Application

- What distinguishes H Type Silicon Carbide Heating Elements from other types? Superior Durability for High-Temp Cycling

- What makes MoSi2 heating elements easy to replace? Achieve Minimal Downtime with Hot-Swap Capability

- What factors should be considered when choosing between MoSi2 and SiC heating elements for sintering furnaces? Optimize Your Sintering Process

- What makes graphite heating elements resistant to thermal shocks? Key Properties Explained

- Why are MoSi2 heating elements considered versatile for industrial applications? Unlock High-Temp Reliability & Efficiency