At its core, the versatility of Molybdenum Disilicide (MoSi₂) heating elements stems from their unique ability to operate reliably at extreme temperatures in oxidizing atmospheres. This is due to a self-healing protective layer that forms during operation, granting them exceptional longevity and chemical stability that other materials cannot match.

The true value of MoSi₂ elements isn't just their ability to get hot, but their capacity to provide consistent, uniform, and long-lasting heat in demanding industrial environments where process failure and downtime are exceptionally costly.

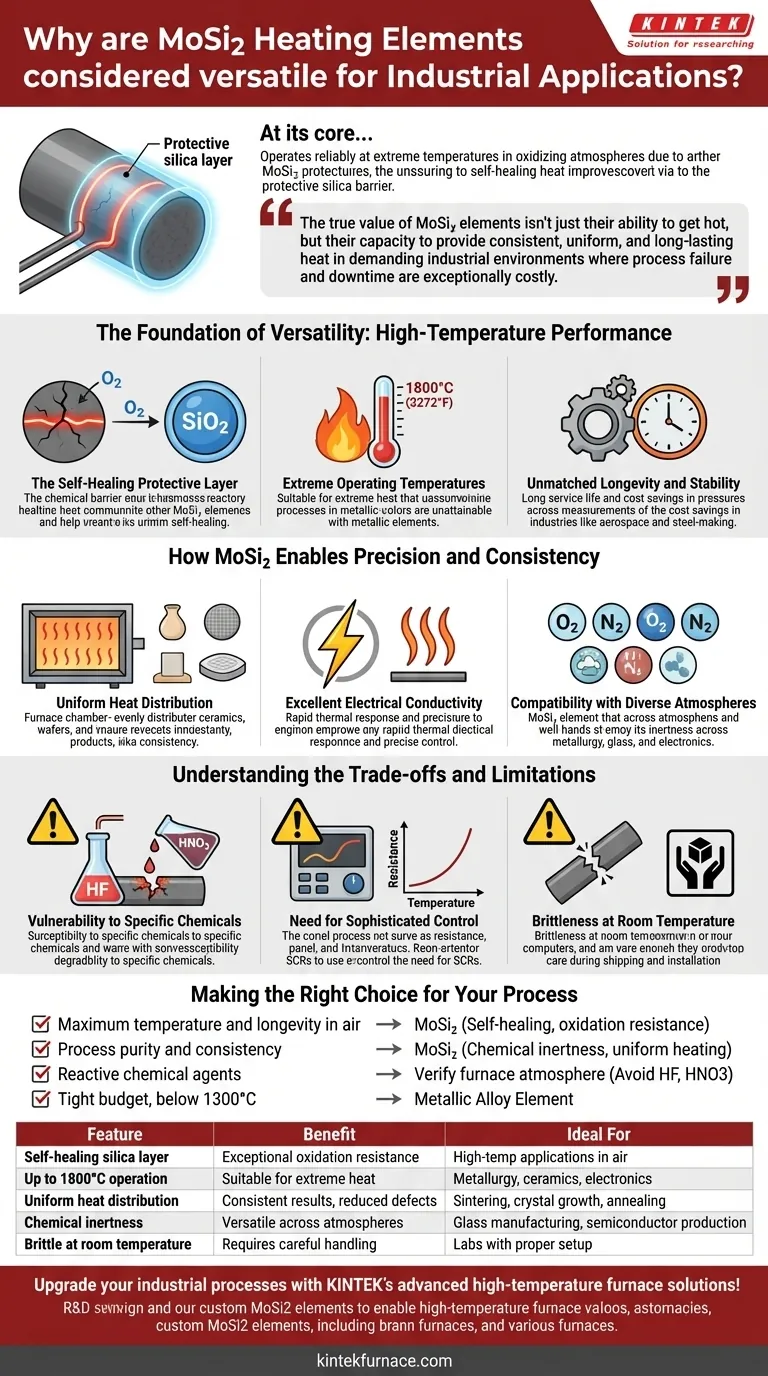

The Foundation of Versatility: High-Temperature Performance

The primary advantage of MoSi₂ is its robust performance under extreme thermal stress. This capability is built on a few key characteristics that work in concert.

The Self-Healing Protective Layer

When heated, MoSi₂ reacts with oxygen in the atmosphere to form a thin, non-porous layer of pure silica (SiO₂) on its surface. This layer acts as a chemical barrier, protecting the underlying element from further oxidation.

If a crack forms in this protective layer due to thermal cycling, the exposed MoSi₂ underneath immediately reacts with oxygen to "heal" the breach. This unique self-repairing function is what gives the element its incredible resistance to high-temperature corrosion.

Extreme Operating Temperatures

Thanks to this protective layer, MoSi₂ elements can operate continuously at temperatures up to 1800°C (3272°F) in air. This makes them suitable for processes that are simply unattainable with most metallic heating elements.

Unmatched Longevity and Stability

The combination of high-temperature capability and self-healing properties results in an exceptionally long service life. For industries like aerospace or steel-making, where furnace downtime can halt production, this reliability translates directly into significant cost savings and operational efficiency.

How MoSi₂ Enables Precision and Consistency

Beyond raw heat, the properties of MoSi₂ are critical for industries that demand precise process control and repeatable results.

Uniform Heat Distribution

MoSi₂ elements are designed to provide highly uniform heat throughout the furnace chamber. This consistency is essential for applications like sintering ceramics, growing crystals, or annealing semiconductor wafers, where even minor temperature variations can ruin the final product.

Excellent Electrical Conductivity

These elements efficiently convert electrical energy into heat energy. This allows for rapid thermal response and precise temperature adjustments, giving operators fine-grained control over the heating cycle.

Compatibility with Diverse Atmospheres

While their performance is optimized in oxidizing atmospheres (like air), their general chemical inertness makes them suitable for a wide range of process environments. This adaptability allows them to be used across metallurgy, glass manufacturing, and electronics production without significant modification.

Understanding the Trade-offs and Limitations

No technology is without its limitations. Objectivity requires understanding where MoSi₂ elements might not be the ideal choice.

Vulnerability to Specific Chemicals

The protective silica layer, while highly resilient, is susceptible to certain chemicals. MoSi₂ elements will be attacked and rapidly degrade in the presence of hydrofluoric acid and nitric acid.

Need for Sophisticated Control

The electrical resistance of MoSi₂ changes significantly as it heats up. They also have a maximum current limit that must be respected to prevent damage. This necessitates the use of advanced power controllers, typically SCRs (Silicon Controlled Rectifiers), to manage the power input accurately.

Brittleness at Room Temperature

Like many ceramics, MoSi₂ elements are relatively brittle at ambient temperatures. While they possess strong impact resistance once hot, special care must be taken during shipping, handling, and installation to avoid fractures.

Making the Right Choice for Your Process

Selecting the right heating element requires matching its capabilities to your primary operational goal.

- If your primary focus is maximum temperature and longevity in air: MoSi₂ is a top-tier choice due to its self-healing oxidation resistance and stability.

- If your primary focus is process purity and consistency: Their chemical inertness and uniform heating make them ideal for sensitive applications like semiconductor and glass manufacturing.

- If your process involves reactive chemical agents: You must verify that your furnace atmosphere is free of hydrofluoric or nitric acids to prevent rapid element degradation.

- If you are operating on a tight budget without a need for extreme temperatures: A less expensive metallic alloy element may be a more suitable choice for applications below 1300°C.

Ultimately, understanding these core principles allows you to leverage the unique advantages of MoSi₂ for reliable and efficient high-temperature operations.

Summary Table:

| Feature | Benefit | Ideal For |

|---|---|---|

| Self-healing silica layer | Exceptional oxidation resistance and longevity | High-temperature applications in air |

| Up to 1800°C operation | Suitable for extreme heat processes | Metallurgy, ceramics, electronics |

| Uniform heat distribution | Consistent results and reduced product defects | Sintering, crystal growth, annealing |

| Chemical inertness | Versatile across various atmospheres | Glass manufacturing, semiconductor production |

| Brittle at room temperature | Requires careful handling and installation | Labs with proper setup and controls |

Upgrade your industrial processes with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable MoSi2 heating elements and custom furnace systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and reducing downtime. Contact us today to discuss how we can optimize your high-temperature applications!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment