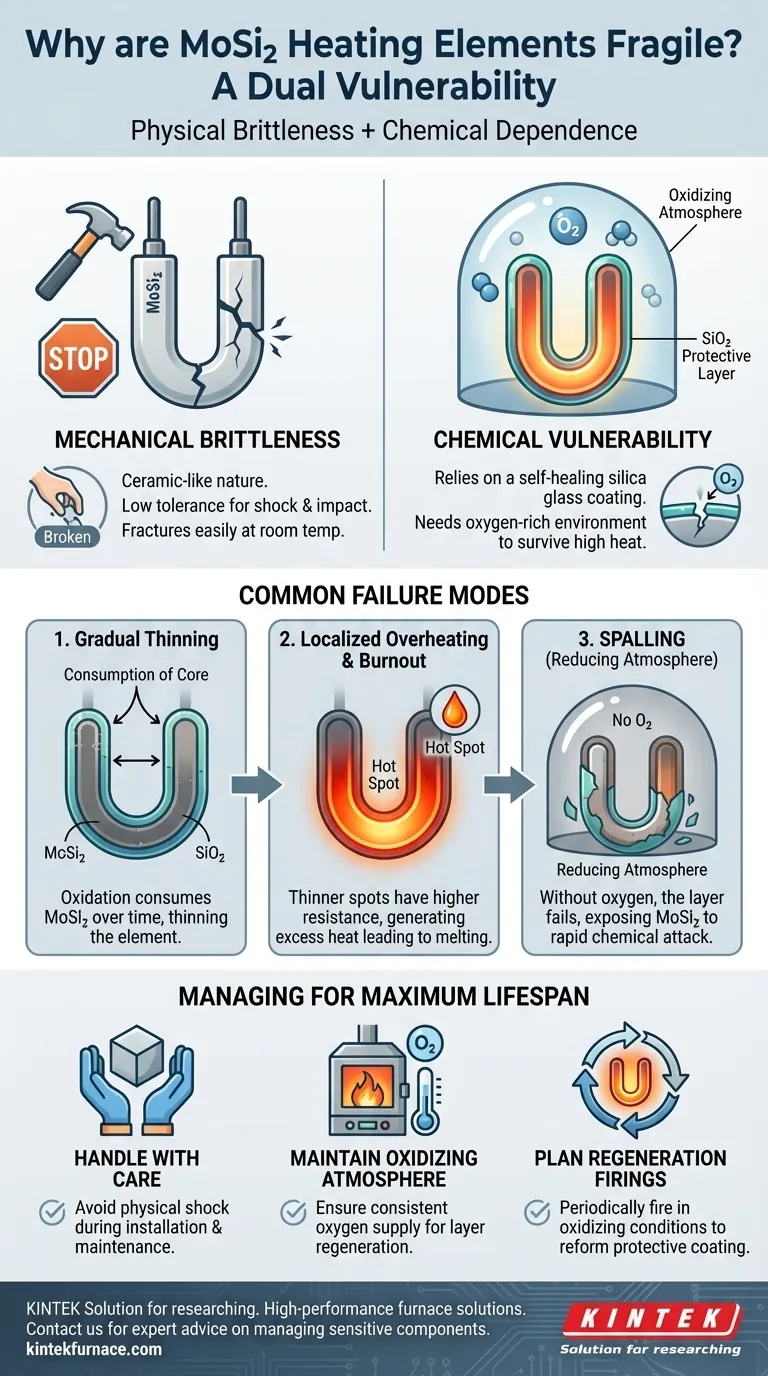

Despite their robust appearance, Molybdenum Disilicide (MoSi₂) heating elements are considered fragile due to their inherent brittleness and low resistance to mechanical shock. However, this physical fragility is only one aspect; their operational vulnerability often stems from chemical degradation, where the protective surface layer that allows them to function at high temperatures is compromised, leading to thinning and eventual failure.

The term "fragile" for MoSi₂ elements describes a dual vulnerability. They are both physically brittle and chemically dependent on a specific operating environment to maintain the self-healing glass layer that protects them from rapid self-destruction at extreme temperatures.

The Two Faces of MoSi₂ Fragility

The fragility of a MoSi₂ element is not a simple matter of being easy to break. It's a complex interplay between its physical properties and its chemical behavior at high temperatures.

Mechanical Brittleness

MoSi₂ elements possess a ceramic-like nature. Like many advanced ceramics, they have high-temperature strength but are brittle at room temperature.

This means they have very low tolerance for mechanical shock. Dropping an element or subjecting it to sharp impacts during installation or furnace maintenance can easily cause it to fracture.

Chemical Vulnerability: The Protective Layer

The reason MoSi₂ elements can operate at incredibly high temperatures is the formation of a thin, protective layer of pure silica (SiO₂), essentially a glass coating.

This layer forms on the element's surface in an oxidizing atmosphere (an environment rich in oxygen). It acts as a barrier, preventing the underlying MoSi₂ material from rapidly oxidizing and burning out.

This SiO₂ layer is self-healing. If a crack or flaw develops, the exposed MoSi₂ reacts with oxygen in the furnace to form new silica, effectively "healing" the breach.

Common Failure Modes Explained

Understanding how these elements fail is key to extending their service life. Failure is rarely a sudden event but rather the result of a gradual process.

Gradual Thinning from Oxidation

Even under ideal conditions, the continuous formation and regeneration of the SiO₂ layer slowly consumes the underlying MoSi₂ material.

Over hundreds or thousands of hours, this process causes the element to become progressively thinner.

Localized Overheating and Burnout

As an element thins, its electrical resistance increases in that area. This increased resistance causes the thinner section to generate more heat than the rest of the element.

Eventually, this spot becomes so thin and hot that the power density is exceeded, leading to localized melting and burnout. This can sometimes be observed as an "orange-peel" texture on the element surface due to grain growth before failure.

Spalling in Reducing Atmospheres

The most severe chemical failure occurs in a reducing atmosphere (an environment lacking sufficient oxygen). Without oxygen, the element cannot form a new protective SiO₂ layer.

If the existing layer is damaged, the element is exposed and can be attacked by the furnace atmosphere, a process known as spalling. This leads to rapid degradation and premature failure.

Understanding the Trade-offs

The use of MoSi₂ elements involves accepting a series of critical trade-offs that dictate how they must be managed.

High Performance vs. Environmental Sensitivity

MoSi₂ offers exceptional performance at very high temperatures, which is its primary advantage. The trade-off is its complete dependence on a specific, oxygen-rich chemical environment to survive.

Long Lifespan vs. Gradual Degradation

These elements are known for their long service life, but this longevity is not unconditional. It assumes correct management of the furnace atmosphere and acknowledges that the element is a consumable part that is always slowly degrading.

Fragility vs. Serviceability

While the elements are fragile, they are uniquely designed for serviceability. Many furnaces allow for the replacement of a failed MoSi₂ element while the furnace is still hot, minimizing production downtime. This practical design feature helps offset the risk of failure.

Managing MoSi₂ Elements for Maximum Lifespan

Your operational strategy should directly address these failure modes to maximize the return on your investment. By understanding the nature of their fragility, you can implement procedures to mitigate it.

- If your primary focus is preventing mechanical shock: Handle elements with extreme care during installation and avoid any physical impact to the furnace while in operation.

- If your primary focus is maximizing element lifespan: Maintain a consistently oxidizing atmosphere within your furnace to support the continuous health of the protective SiO₂ layer.

- If you must operate in a reducing atmosphere: Plan for periodic "regeneration" firings in an oxidizing environment at high temperatures to "heal" the elements by reforming their protective coatings.

Understanding this balance between chemical resilience and operational requirements is the key to unlocking the full potential of these high-performance components.

Summary Table:

| Fragility Type | Key Characteristics | Common Failure Modes |

|---|---|---|

| Mechanical Brittleness | Low tolerance for shock, prone to fracture from impact | Damage during installation, physical shock |

| Chemical Vulnerability | Dependent on protective SiO₂ layer in oxidizing atmospheres | Gradual thinning, localized overheating, spalling in reducing atmospheres |

Maximize the performance and lifespan of your high-temperature processes with KINTEK's advanced furnace solutions.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements—especially when managing sensitive components like MoSi₂ heating elements.

Contact us today to discuss how our expertise can enhance your lab's efficiency and reliability!

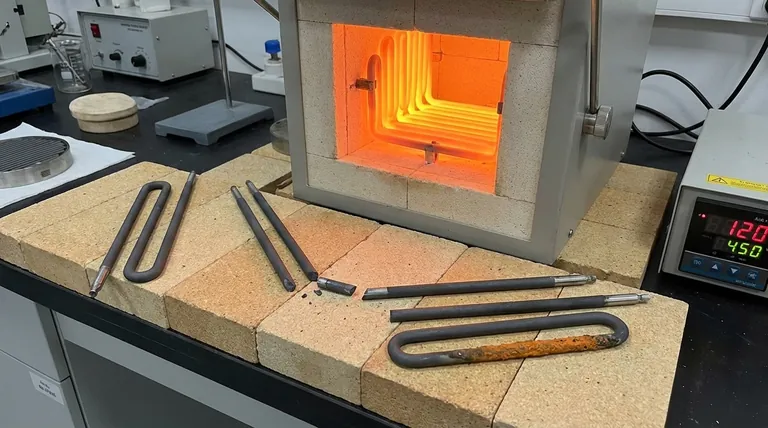

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability