For applications demanding extreme heat, Molybdenum Disilicide (MoSi2) heating elements are a leading solution. Their primary advantages are an exceptionally high operating temperature, remarkable longevity due to a unique self-healing property, and stable electrical resistance that simplifies furnace operation and maintenance.

The core advantage of a MoSi2 element is not just its heat tolerance, but its ability to form a protective, self-repairing layer of silica glass at high temperatures. This single characteristic is the foundation for its superior oxidation resistance, long lifespan, and reliable performance in oxidizing environments.

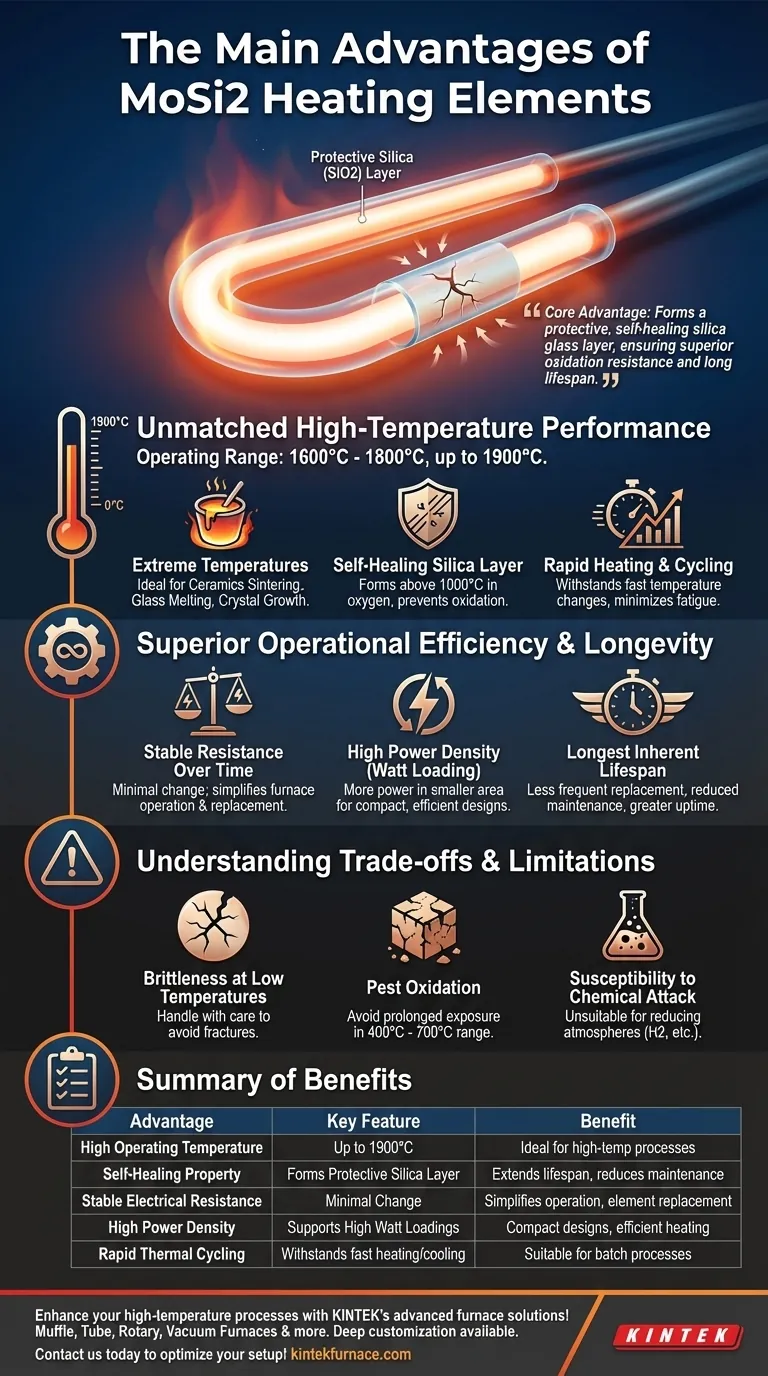

The Foundation: Unmatched High-Temperature Performance

The defining feature of MoSi2 is its ability to perform reliably where many other materials fail. This capability stems from its unique material science.

Operating in Extreme Temperatures

MoSi2 elements are designed to operate consistently at temperatures between 1600°C and 1800°C (2912°F - 3272°F), with specialized variants capable of reaching up to 1900°C (3452°F). This makes them indispensable for processes like ceramics sintering, glass melting, and crystal growth.

The "Self-Healing" Silica Layer

When heated above approximately 1000°C in an oxygen-rich atmosphere, the element's surface reacts to form a thin, non-porous layer of quartz glass (SiO2). This protective layer prevents further oxidation of the underlying material. If a crack or spall occurs, the exposed MoSi2 will simply re-oxidize, effectively "healing" the damage and restoring the protective barrier.

Rapid Heating and Thermal Cycling

The stability of this silica layer allows MoSi2 elements to withstand fast heating rates and repeated thermal cycles without significant degradation. This is critical for batch processes that require frequent temperature changes, as it minimizes element fatigue and extends service life.

Superior Operational Efficiency and Longevity

Beyond pure temperature resistance, MoSi2 elements offer tangible benefits that lower operational costs and reduce downtime.

Stable Resistance Over Time

Unlike many metallic elements whose resistance changes significantly as they age, MoSi2 maintains a remarkably stable resistance throughout its life. This is a crucial advantage, as it allows new elements to be connected in series with older ones without causing imbalances in power distribution.

High Power Density (Watt Loading)

MoSi2 elements can support very high watt loadings. This means more power can be concentrated in a smaller surface area, enabling more compact furnace designs and delivering heat to the workload more efficiently.

The Longest Inherent Lifespan

Because of their self-healing oxidation resistance, MoSi2 elements possess the longest inherent service life of any conventional metallic or ceramic heating element. This translates directly to less frequent replacement, reduced maintenance labor, and greater furnace uptime.

Understanding the Trade-offs and Limitations

No material is without its drawbacks. Acknowledging the limitations of MoSi2 is key to its successful implementation.

Brittleness at Low Temperatures

While robust at operating temperature, MoSi2 is a ceramic material and is very brittle at room temperature. Care must be taken during shipping, handling, and installation to avoid mechanical shock, which can easily cause fractures.

"Pest" Oxidation

In a specific temperature range of roughly 400°C to 700°C, MoSi2 can undergo a destructive phenomenon known as "pesting." In this range, the material can rapidly disintegrate into powder. This is avoided by moving through this temperature band quickly during both heat-up and cool-down.

Susceptibility to Chemical Attack

The protective silica layer is the key to the element's survival. Certain atmospheres can attack this layer and cause rapid failure. MoSi2 is not suitable for use in reducing atmospheres (like hydrogen or cracked ammonia) or in the presence of certain chemicals that react with silica.

Making the Right Choice for Your Application

Selecting the right heating element requires matching its strengths to your process goals.

- If your primary focus is reaching the highest possible temperatures: MoSi2 is the premier choice, offering stability and performance in oxidizing atmospheres well above 1700°C.

- If your primary focus is long-term stability and minimal maintenance: The stable resistance and self-healing nature of MoSi2 reduce the need for element matching and frequent replacement, lowering the total cost of ownership.

- If your primary focus is process efficiency and speed: The ability to handle high watt loads and rapid thermal cycling makes MoSi2 ideal for high-throughput batch furnaces.

- If your process involves a reducing or reactive chemical atmosphere: You must exercise extreme caution and likely choose an alternative element, as MoSi2 will be chemically attacked and fail prematurely.

For demanding, high-temperature processes in air or oxygen, MoSi2 heating elements provide an unparalleled combination of performance, longevity, and operational stability.

Summary Table:

| Advantage | Key Feature | Benefit |

|---|---|---|

| High Operating Temperature | Up to 1900°C | Ideal for ceramics, glass melting, and crystal growth |

| Self-Healing Property | Forms protective silica layer | Extends lifespan and reduces maintenance |

| Stable Electrical Resistance | Minimal change over time | Simplifies furnace operation and element replacement |

| High Power Density | Supports high watt loadings | Enables compact furnace designs and efficient heating |

| Rapid Thermal Cycling | Withstands fast heating and cooling | Suitable for batch processes with frequent temperature changes |

Enhance your laboratory's high-temperature processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable heating elements and systems like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, delivering superior performance and cost savings. Contact us today to discuss how we can optimize your setup!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat