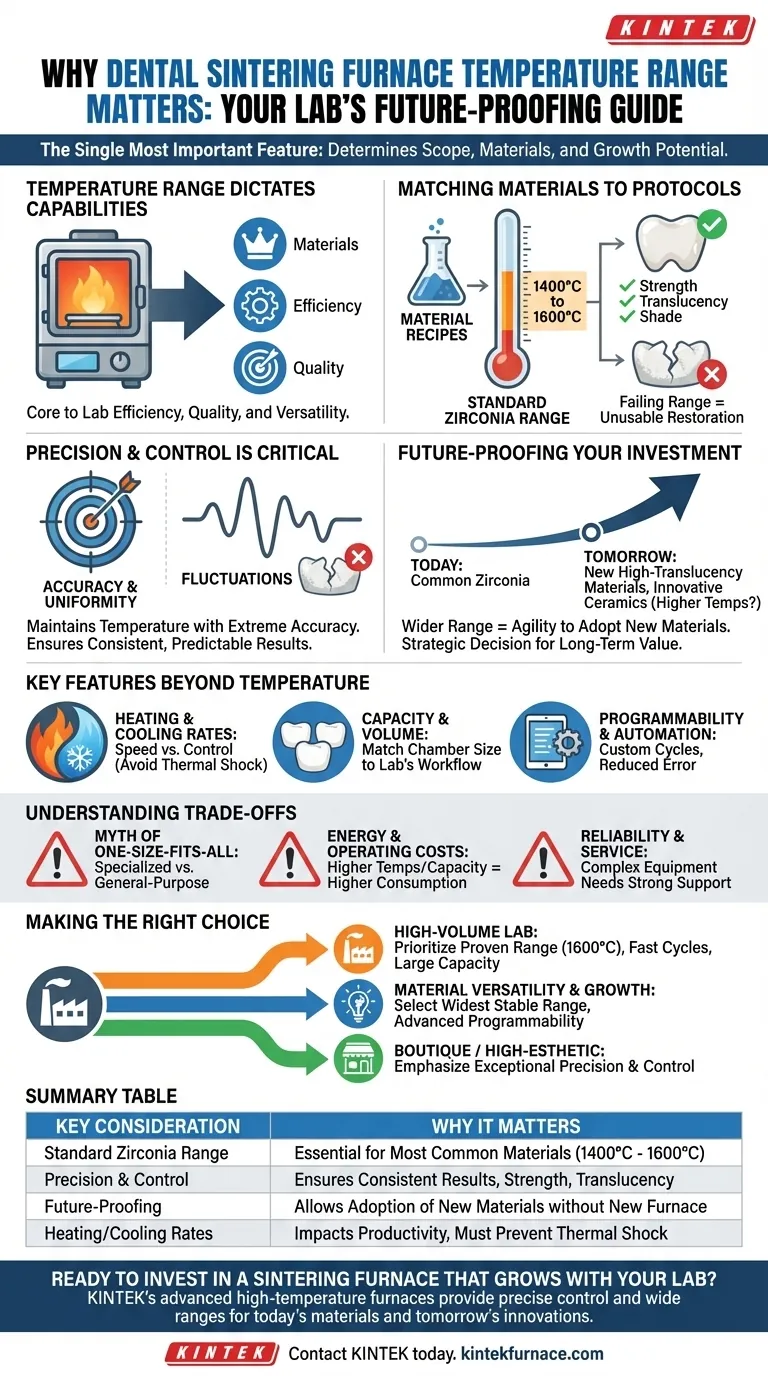

In short, the temperature range of a dental sintering furnace is the single most important feature because it directly determines the scope and type of materials your lab can process. If a furnace cannot reach the specific temperature required by a material like zirconia, you simply cannot use it, limiting your services and potential for growth.

The core issue isn't just about meeting today's needs, but about future-proofing your investment. A furnace with a wide and precise temperature range ensures your practice can adapt to the inevitable evolution of new dental materials without requiring a new machine.

Why Temperature Range Dictates Your Lab's Capabilities

A sintering furnace is a long-term investment, and its technical specifications directly impact your lab's efficiency, quality, and versatility. The temperature range sits at the heart of these capabilities.

Matching Materials to Sintering Protocols

Every dental material, especially modern zirconia, has a precise sintering protocol or "recipe" provided by the manufacturer. This protocol specifies the exact peak temperature and hold times required to achieve the desired physical properties like strength, translucency, and shade.

For most common dental zirconia, a furnace with a temperature range that comfortably reaches 1400°C to 1600°C is considered the standard. Failing to reach this temperature will result in a weak, chalky, and clinically unusable restoration.

The Critical Role of Precision and Control

The maximum temperature is only half the story. The furnace must also be able to maintain that temperature with extreme accuracy.

Fluctuations in temperature can compromise the final restoration's integrity. A high-quality furnace provides uniform heat distribution and precise control, ensuring consistent and predictable results every single time.

Future-Proofing Your Investment

The field of dental materials is constantly advancing. New high-translucency zirconia or innovative ceramics may require different, and sometimes higher, sintering temperatures.

Choosing a furnace with a wider temperature range than you currently need is a strategic decision. It gives your lab the agility to adopt new materials and techniques, ensuring your equipment remains relevant and valuable for years to come.

Key Features Beyond Temperature

While temperature range is paramount, it exists within an ecosystem of other features that collectively determine the furnace's value to your lab.

Heating and Cooling Rates

The speed at which a furnace heats up and cools down directly impacts your turnaround times. Faster cycles increase productivity, but they must be carefully controlled to prevent thermal shock, which can cause restorations to crack.

Capacity and Production Volume

The furnace's internal chamber size dictates how many units you can sinter in a single cycle. Your choice should align with your lab's current and projected production volume to avoid creating a workflow bottleneck.

Programmability and Automation

Modern furnaces offer advanced programmability, allowing you to create and save custom cycles for different materials. This automation reduces the risk of human error and ensures every restoration is processed according to its exact specifications.

Understanding the Trade-offs

Making an informed decision requires acknowledging the potential downsides and common pitfalls associated with this technology.

The Myth of the "One-Size-Fits-All" Furnace

A furnace with an extremely wide temperature range might seem appealing, but it may not be optimized for the specific materials you use most. Sometimes, a furnace designed specifically for zirconia will outperform a general-purpose unit in terms of consistency and energy efficiency for that particular task.

Energy Consumption and Operating Costs

Higher maximum temperatures and larger capacities naturally lead to higher energy consumption. Factoring in the long-term operating costs is essential for calculating the true return on investment, especially for high-volume labs.

Reliability and Service Support

A furnace is a complex piece of equipment that requires maintenance. Investing in a unit from a reputable brand with a strong warranty and accessible customer support is critical. A furnace with a perfect temperature range is useless if it is unreliable or difficult to service.

Making the Right Choice for Your Goal

Your selection should be guided by a clear understanding of your lab's primary objectives.

- If your primary focus is high-volume, standard zirconia restorations: Prioritize a furnace with a proven, reliable range up to 1600°C, fast cycle times, and a large capacity.

- If your primary focus is material versatility and future growth: Select a furnace with the widest stable temperature range you can afford and advanced programmability to accommodate new materials.

- If your primary focus is a boutique lab with custom, high-esthetic cases: Emphasize a furnace known for its exceptional temperature precision and control, even if its capacity is smaller.

Ultimately, viewing the temperature range not as a single specification but as a direct measure of your lab's future capabilities will guide you to the most strategic investment.

Summary Table:

| Key Consideration | Why It Matters |

|---|---|

| Standard Zirconia Range | Essential for sintering most common materials (1400°C - 1600°C). |

| Precision & Control | Ensures consistent results, strength, and translucency of restorations. |

| Future-Proofing | Allows adoption of new materials without requiring a new furnace. |

| Heating/Cooling Rates | Impacts productivity and must be controlled to prevent thermal shock. |

Ready to invest in a sintering furnace that grows with your lab?

KINTEK's advanced high-temperature furnaces are engineered for precision and versatility. Leveraging exceptional R&D and in-house manufacturing, we provide dental laboratories with robust solutions featuring the precise temperature control and wide ranges needed to master today's materials and embrace tomorrow's innovations.

Contact KINTEL today to discuss how our furnace solutions can future-proof your capabilities and enhance your lab's efficiency.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab