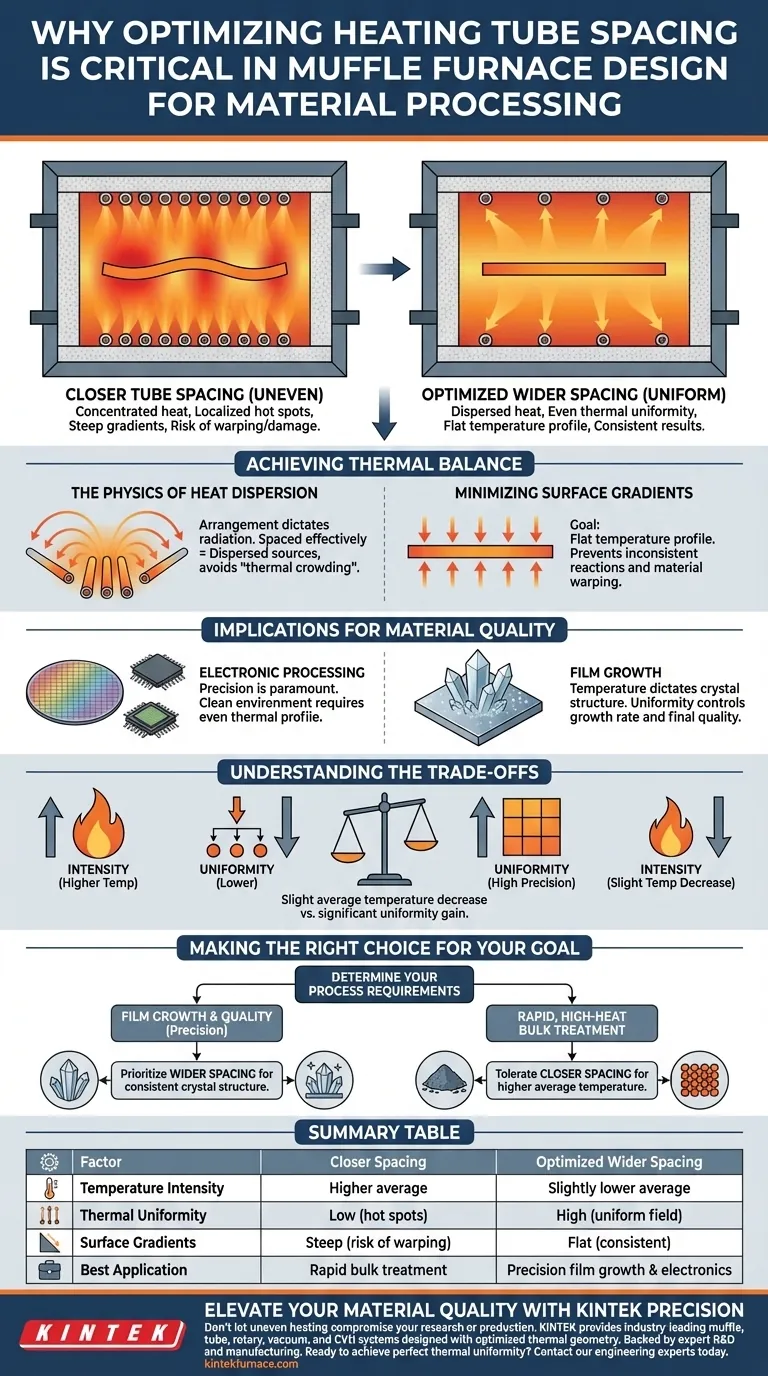

Optimizing heating tube spacing is the definitive factor in establishing thermal uniformity within a muffle furnace. By strategically adjusting the distance between these heat sources, you ensure that heat is dispersed evenly, preventing localized hot spots and minimizing temperature gradients across the surface of the workpiece.

While wider tube spacing may result in a slight reduction in the average overall temperature, it significantly enhances the uniformity of the temperature field, which is often the more critical metric for high-precision material processing.

Achieving Thermal Balance

The Physics of Heat Dispersion

The arrangement of heating tubes dictates how energy radiates into the furnace chamber. When tubes are spaced effectively, the heat sources are dispersed rather than concentrated.

This dispersion is necessary to avoid "thermal crowding." If tubes are too close, heat creates intense, localized zones that can damage sensitive materials.

Minimizing Surface Gradients

For the workpiece inside the furnace, the goal is a flat temperature profile. Poor spacing leads to temperature gradients on the material's surface.

By optimizing the gap between tubes, you ensure the entire surface of the workpiece receives consistent thermal energy. This prevents warping or inconsistent chemical reactions across the material.

Implications for Material Quality

Criticality in Electronic Processing

In applications such as electronic material processing or optical material fabrication, precision is paramount.

Muffle furnaces are specifically chosen here because they isolate the material from combustion byproducts. However, a clean environment is useless if the thermal profile is uneven.

Controlling Crystal Structure

In processes like film growth, the temperature directly dictates the crystal structure and physical properties of the film.

Uniform heating allows for precise control over the atmosphere and temperature. This control improves both the rate of growth and the ultimate quality of the film, ensuring the final product meets strict specifications.

Understanding the Trade-offs

Intensity vs. Uniformity

There is a distinct trade-off when increasing tube spacing to gain uniformity.

As you widen the space between tubes to smooth out gradients, you may observe a slight decrease in the average temperature of the chamber.

Balancing Efficiency

Designers must balance the need for high heat with the need for even heat.

For most high-specification tasks, such as semiconductor work, the gain in uniformity vastly outweighs the minor loss in maximum temperature intensity.

Making the Right Choice for Your Goal

To determine the optimal design for your specific application, consider your process requirements:

- If your primary focus is Film Growth and Quality: Prioritize wider tube spacing to ensure the strict thermal uniformity required for consistent crystal structures.

- If your primary focus is Rapid, High-Heat Bulk Treatment: You may tolerate tighter spacing to maximize average temperature, provided surface gradients are acceptable for the material.

Precision in design leads to precision in results; prioritize geometry to control thermal outcome.

Summary Table:

| Factor | Closer Tube Spacing | Optimized Wider Spacing |

|---|---|---|

| Temperature Intensity | Higher average temperature | Slightly lower average temperature |

| Thermal Uniformity | Low (prone to localized hot spots) | High (uniform temperature field) |

| Surface Gradients | Steep (risk of warping) | Flat (consistent energy distribution) |

| Best Application | Rapid, high-heat bulk treatment | Precision film growth & electronics |

Elevate Your Material Quality with KINTEK Precision

Don't let uneven heating compromise your research or production. KINTEK provides industry-leading muffle, tube, rotary, vacuum, and CVD systems designed with optimized thermal geometry. Backed by expert R&D and manufacturing, our high-temp lab furnaces are fully customizable to meet your unique precision requirements.

Ready to achieve perfect thermal uniformity? Contact our engineering experts today to find the ideal furnace configuration for your application.

Visual Guide

References

- Yuchen Wang, Haisheng Fang. Research and optimization of temperature uniformity of high-precision muffle furnace. DOI: 10.1088/1742-6596/3009/1/012076

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why use a muffle furnace for AAS concrete testing? Achieve Precise Thermal Analysis for High-Temperature Performance

- What role does a high-precision muffle furnace play in ceramic powder pre-calcination? Master Phase & Purity Control

- What are the special features of muffle furnaces? Achieve Clean, Precise Heat for Your Lab

- Why is a high-temperature muffle furnace required for the incineration treatment of titanium dioxide nanoparticles?

- What is the function of a muffle furnace in plant leaf ash analysis? Master Precision Dry Ashing

- Why is a laboratory muffle furnace necessary for nickel-based superalloys? Expert Stabilization & Hardening Guide

- What safety measures should be observed regarding the surroundings of a muffle furnace? Ensure a Secure Lab Setup

- What is the function of a muffle furnace in LSCF modification? Achieve Precise Thermal Foundation for Advanced Ceramics