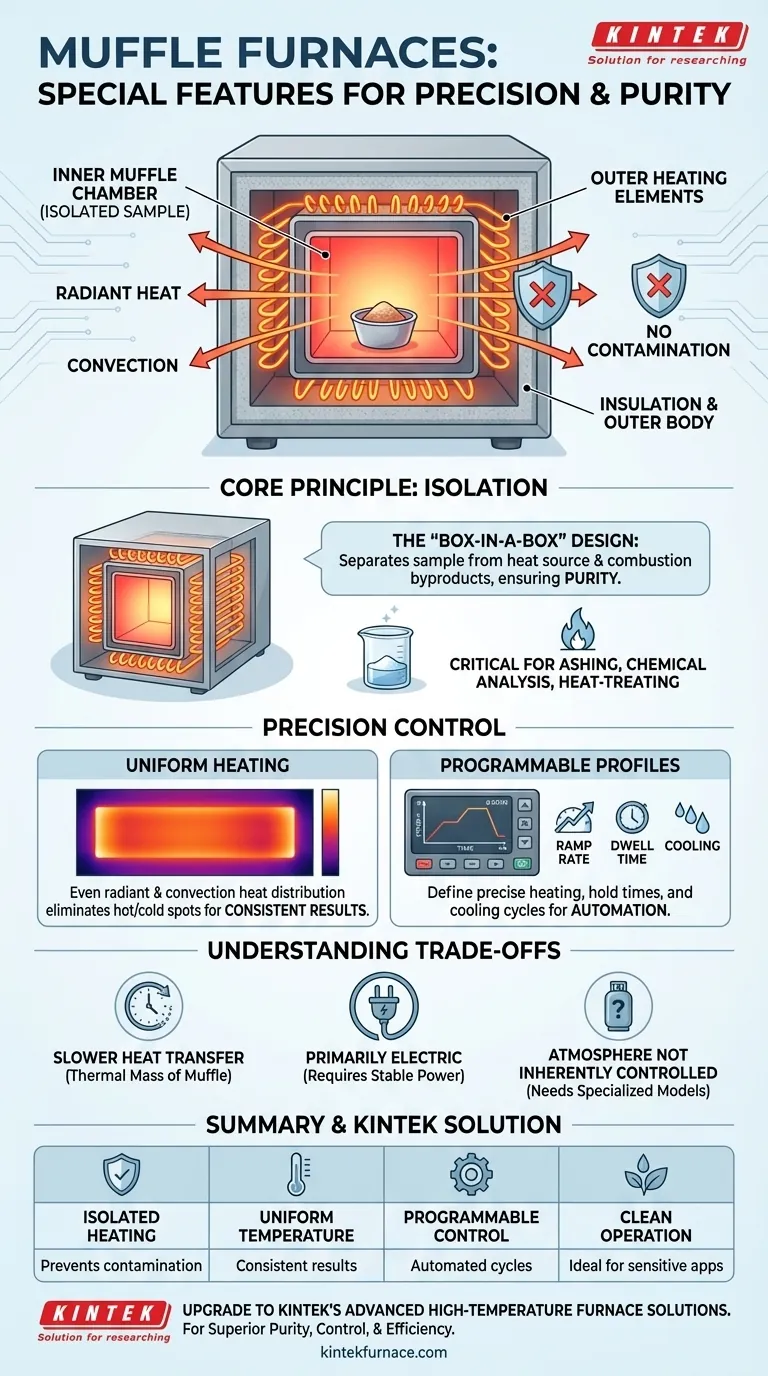

At its core, a muffle furnace is defined by its ability to provide extremely precise, uniform, and clean heat. Its special features all stem from a single design principle: isolating the material being heated from the actual heat source. This is achieved through an internal chamber, or "muffle," which prevents contamination from combustion byproducts or direct contact with electric heating elements, ensuring the integrity of the sample.

The defining feature of a muffle furnace isn't just its ability to get hot, but its ability to create a highly controlled and uncontaminated thermal environment. This makes it an indispensable tool for processes where material purity and treatment consistency are non-negotiable.

The Core Principle: Isolating the Sample

The name "muffle furnace" directly describes its most important feature. Understanding this concept is key to understanding its value.

What is a "Muffle"?

A muffle is a sealed, high-temperature chamber that sits inside the furnace's main insulated body. The heating elements heat the outside of this muffle.

Think of it as a "box-in-a-box" design. The outer box contains the insulation and heating elements, while the inner box (the muffle) holds your sample, workpiece, or crucible.

How This Prevents Contamination

This separation is critical. The sample inside the muffle is never exposed to the byproducts of combustion (in a fuel-fired furnace) or the oxidizing effects of direct contact with glowing-hot electric elements.

This makes the muffle furnace essential for applications like ashing, chemical analysis, and heat-treating sensitive alloys where even minor contamination could ruin the results.

Precision Control Over the Thermal Process

Beyond just providing clean heat, muffle furnaces offer an exceptional degree of control over the entire heating and cooling cycle.

Uniform and Homogeneous Heating

Because the muffle is heated from all sides, it radiates heat evenly inward. This combination of radiant and convection heat transfer ensures the entire chamber, and thus your entire sample, is held at a highly uniform temperature.

This homogeneity is vital for consistent material testing, ensuring that results are repeatable and not skewed by hot or cold spots within the furnace.

Programmable Temperature Control

Modern muffle furnaces feature advanced digital controllers. These are not simple thermostats; they allow for fully programmable control of the thermal profile.

Users can define precise heating rates (e.g., increase by 10°C per minute), hold times at specific temperatures (e.g., dwell at 800°C for two hours), and controlled cooling rates. This level of automation is crucial for complex metallurgical and ceramic processes.

Understanding the Trade-offs

While powerful, the muffle furnace design has inherent trade-offs that are important to recognize.

Slower Heat Transfer

The muffle itself acts as a layer of thermal mass. Because heat must first saturate the muffle before transferring to the chamber, heating and cooling times can be slower compared to direct-heat or forced-air convection ovens.

Primarily Electric Operation

The vast majority of modern lab-scale muffle furnaces are electric. This ensures clean operation but also means they require a significant and stable power supply. For very large industrial applications, this can be a limitation compared to gas-fired alternatives.

Atmosphere is Not Inherently Controlled

While a muffle prevents contamination from the furnace elements, a standard model heats the sample in ambient air. If your process requires a vacuum or an inert gas atmosphere (like nitrogen or argon), you will need a specialized model equipped with gas ports and vacuum seals.

Is a Muffle Furnace Right for Your Application?

Choosing the right furnace depends entirely on your primary objective. This equipment is a specialized tool, not a universal solution for all heating needs.

- If your primary focus is material purity and avoiding contamination: The isolated muffle design is its most critical and defining advantage.

- If your primary focus is achieving highly consistent and repeatable results: The uniform heating and programmable temperature controls are essential for this goal.

- If your primary focus is simply drying or low-temperature baking: A less expensive laboratory oven or convection furnace is likely a more suitable and cost-effective choice.

By understanding its core design of isolated, uniform heating, you can determine if a muffle furnace is the right instrument to achieve your specific technical goals.

Summary Table:

| Feature | Description |

|---|---|

| Isolated Heating | Prevents contamination by separating sample from heat source and combustion byproducts. |

| Uniform Temperature | Provides even heat distribution through radiant and convection methods for consistent results. |

| Programmable Control | Allows precise setting of heating rates, hold times, and cooling cycles for automation. |

| Clean Operation | Primarily electric, ensuring no contamination in applications like ashing and chemical analysis. |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for superior purity, control, and efficiency. Contact us today to discuss how our furnaces can enhance your processes and deliver consistent, contamination-free results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary role of a muffle furnace in the annealing process of AlCrTiVNbx alloys? Enhance Alloy Strength

- How do repeat sintering processes and specialized sintering molds address the technical challenges of manufacturing oversized flywheel rotor components? Expand Scale and Integrity

- Why are precision stirring and drying equipment necessary for photocatalytic materials? Master Microstructure Control

- What is the primary use of a muffle furnace in the assembly of side-heated resistive gas sensors? Expert Annealing Guide

- What role does a muffle furnace play in analyzing the combustion residues? Optimize Your Composite Char Analysis