The intervention of precision heat treatment is critical because the Laser Powder Bed Fusion (LPBF) process subjects AlSi10Mg to extreme thermal conditions that compromise the part's internal stability. Although industrial-grade LPBF equipment achieves nearly 100% relative density using high-power lasers, the resulting rapid cooling rates generate significant internal residual stresses that must be neutralized.

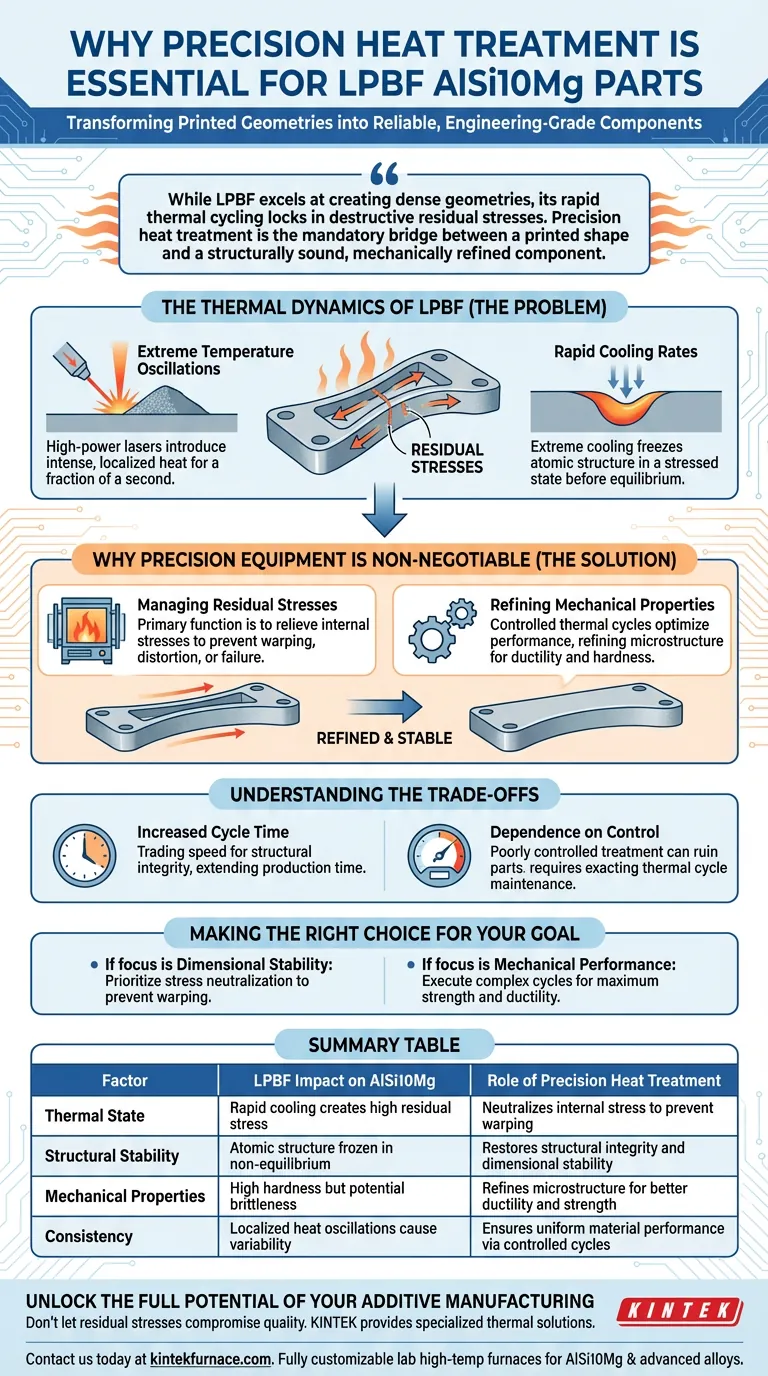

While LPBF excels at creating dense geometries, its rapid thermal cycling locks in destructive residual stresses. Precision heat treatment is the mandatory bridge between a printed shape and a structurally sound, mechanically refined component.

The Thermal Dynamics of LPBF

The root cause of the need for heat treatment lies in the physics of the printing process itself. It is not a flaw in the manufacturing, but a byproduct of how the material is formed.

Extreme Temperature Oscillations

LPBF utilizes high-power lasers to melt fine layers of powder. This introduces intense, localized heat into the material for a fraction of a second.

Rapid Cooling Rates

As the laser moves away, the molten metal solidifies almost instantly. This extreme cooling rate freezes the atomic structure in a stressed state before it can naturally reach equilibrium.

Why Precision Equipment is Non-Negotiable

Standard heating methods are often insufficient for additive manufacturing applications. The specific needs of AlSi10Mg parts produced via LPBF require equipment capable of exacting control.

Managing Residual Stresses

The primary function of this equipment is to relieve the internal residual stresses caused by the printing process. Without this intervention, parts may warp, distort, or fail prematurely under load.

Refining Mechanical Properties

Beyond stress relief, the material requires controlled thermal cycles to optimize its performance. Precision equipment ensures the alloy reaches the exact temperatures needed to refine its final mechanical properties, such as ductility and hardness.

Understanding the Trade-offs

While heat treatment is essential, it introduces additional variables into the manufacturing chain that must be managed.

Increased Cycle Time

Implementing a precision heat treatment step inevitably extends the total production time. You are trading speed for structural integrity, a necessary cost for functional parts.

Dependence on Control

The term "precision" is operative here; poorly controlled heat treatment can ruin a perfectly printed part. If the thermal cycle is not maintained accurately, you risk altering the material properties beyond the desired specification.

Making the Right Choice for Your Goal

To maximize the utility of your AlSi10Mg components, you must align your post-processing strategy with your performance requirements.

- If your primary focus is Dimensional Stability: Prioritize heat treatment cycles designed specifically to neutralize internal residual stresses to prevent warping.

- If your primary focus is Mechanical Performance: Ensure your equipment can execute complex, controlled thermal cycles to refine the alloy's microstructure for maximum strength.

Precision heat treatment transforms a printed geometry into a reliable, engineering-grade component.

Summary Table:

| Factor | LPBF Impact on AlSi10Mg | Role of Precision Heat Treatment |

|---|---|---|

| Thermal State | Rapid cooling creates high residual stress | Neutralizes internal stress to prevent warping |

| Structural Stability | Atomic structure frozen in non-equilibrium | Restores structural integrity and dimensional stability |

| Mechanical Properties | High hardness but potential brittleness | Refines microstructure for better ductility and strength |

| Consistency | Localized heat oscillations cause variability | Ensures uniform material performance via controlled cycles |

Unlock the Full Potential of Your Additive Manufacturing

Don't let residual stresses compromise the quality of your 3D-printed components. KINTEK provides the specialized thermal solutions necessary to transform raw LPBF geometries into high-performance, engineering-grade parts.

Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Our lab high-temp furnaces are fully customizable to meet the exacting thermal cycle requirements of AlSi10Mg and other advanced alloys.

Ready to refine your post-processing? Contact us today to discuss your unique needs with our technical team.

Visual Guide

References

- Busisiwe J. Mfusi, Ntombi Mathe. Optimisation of the Heat Treatment Profile for Powder-Bed Fusion Built AlSi10Mg by Age Hardening and Ice-Water Quenching. DOI: 10.3390/met14030292

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What is the primary purpose of using a vacuum drying oven at 100°C? Optimize Aluminum Foil Coating Performance

- Why is a homogeneous reactor used for crystallization? Achieve 100% Thermal Uniformity for Pure Crystals

- What is the purpose of preheating metal molds? Enhance Fluidity and Quality in Aluminum-Lithium Squeeze Casting

- What is the purpose of performing a final annealing treatment? Optimize Your Heterojunction Device Performance

- Why is precise control of heating and cooling rates necessary for iron-doped ceria? Optimize Your Catalyst Performance

- How does a high-temperature laboratory furnace contribute to the formation of high-quality CsV3Sb5 single crystals?

- What is the purpose of magnetron sputtering in N-I-P CsPbBr3 detectors? Optimize Charge Transport & Stability

- What are the main types of sintering methods for metals, ceramics, and refractory intermetallic compounds powders? Optimize Your Material Processing