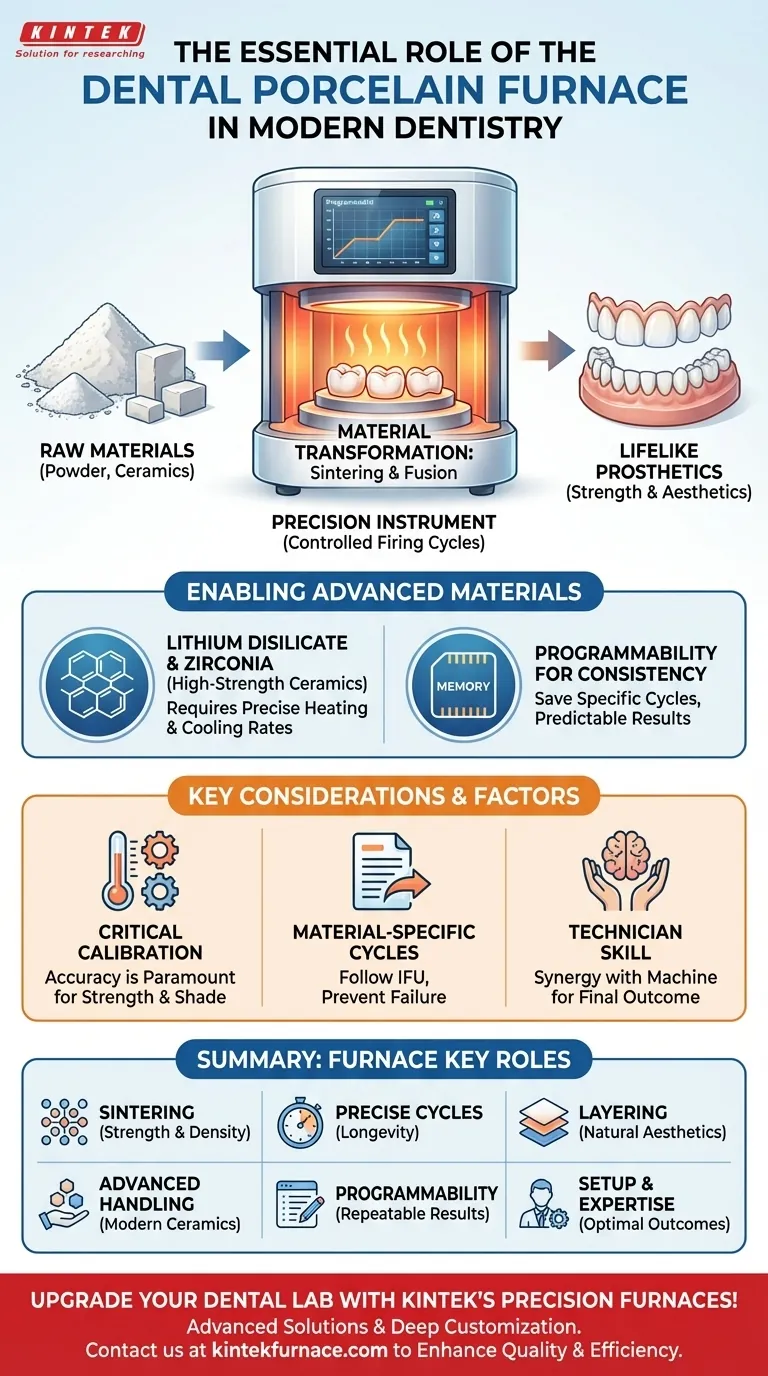

In modern restorative dentistry, the porcelain furnace is the essential apparatus that transforms ceramic materials into durable, lifelike dental prosthetics. It is not merely an oven; it is a precision instrument that enables the fabrication of crowns, veneers, and bridges that meet the highest standards of function and aesthetics. Without it, the advanced ceramic restorations that define contemporary dentistry would be impossible to create.

The core function of a dental porcelain furnace is not simply to heat material, but to execute highly specific, programmable firing cycles. This precise control over temperature and time is what unlocks the intended strength, color, and translucency of advanced dental ceramics.

The Furnace's Role in Material Transformation

A dental furnace is where the science of material transformation happens. It takes raw, workable ceramic and, through a controlled process, converts it into a final restoration with the properties of a natural tooth.

From Powder to Prosthesis

The process, known as firing or sintering, uses high temperatures to fuse ceramic particles together. This compacts the material, eliminates porosity, and creates a solid, dense structure that can withstand the forces of chewing.

Achieving Optimal Strength and Durability

Each type of dental ceramic has a specific temperature and time protocol required to achieve its maximum strength. A modern furnace executes these programs with extreme precision, ensuring the final restoration is not brittle and will have a long clinical service life.

Mastering Aesthetics and Translucency

Creating a lifelike restoration is an art form enabled by technology. The furnace allows technicians to build up layers of porcelain with varying shades and opacities, firing each layer to mimic the natural depth, color gradient, and translucency of a real tooth.

Enabling the Use of Advanced Dental Materials

The evolution of dental furnaces has gone hand-in-hand with the development of new materials. Modern furnaces are engineered to handle the complex requirements of the latest generation of dental ceramics.

Beyond Traditional Metal-Ceramics

While furnaces have long been used for porcelain-fused-to-metal (PFM) crowns, their capabilities are most critical for today's all-ceramic restorations. These materials offer superior aesthetics but demand far more stringent processing.

Firing High-Strength All-Ceramics

Materials like lithium disilicate and zirconia offer exceptional strength and beauty, but they are unforgiving. Their crystalline structures require incredibly precise heating and cooling rates to prevent internal stresses and fractures, a task only a modern, programmable furnace can manage.

Programmability for Unmatched Consistency

Technicians can save specific firing programs for different materials and restoration types. This programmability ensures that every restoration is fired under identical, optimal conditions, leading to predictable results and minimizing costly remakes.

Understanding the Key Considerations

While essential, the furnace is a tool whose effectiveness depends on proper use and understanding of its limitations. The quality of the output is not guaranteed by the machine alone.

The Critical Importance of Calibration

A furnace's temperature accuracy is paramount. An improperly calibrated furnace, even if off by only a few degrees, can under-fire or over-fire a restoration, compromising its strength, fit, and shade. Regular calibration is non-negotiable for any serious dental laboratory.

Material-Specific Firing Cycles

There is no universal firing program. Each ceramic from each manufacturer comes with a specific "instructions for use" (IFU) document detailing the required firing cycle. Deviating from these parameters is a primary cause of restoration failure.

The Indispensable Role of Technician Skill

The furnace executes a program, but a skilled technician must build the restoration, choose the right program, and correctly place the work inside the chamber. The final outcome remains a synergy between the technician's expertise and the machine's precision.

Making the Right Choice for Your Goal

The importance of the furnace is directly tied to the type of restorations a dental laboratory aims to produce. Its features must align with your clinical and aesthetic objectives.

- If your primary focus is foundational strength for PFM or simple monolithic crowns: A reliable furnace with accurate temperature control and basic programming is sufficient.

- If your primary focus is high-end, multi-layered aesthetic restorations: A furnace with advanced, customizable programs and superior vacuum control is essential to manage translucency and vitality.

- If your primary focus is processing zirconia frameworks: You will need a dedicated high-temperature sintering furnace, which is distinct from a porcelain furnace used for layering ceramic.

Ultimately, the dental porcelain furnace is the critical instrument that translates material science and artistic skill into successful and durable clinical outcomes.

Summary Table:

| Aspect | Key Role |

|---|---|

| Material Transformation | Fuses ceramic particles via sintering for strength and density. |

| Strength & Durability | Executes precise temperature cycles to maximize restoration longevity. |

| Aesthetics & Translucency | Enables layering and firing for natural tooth-like appearance. |

| Advanced Material Handling | Supports high-strength ceramics like lithium disilicate and zirconia. |

| Programmability & Consistency | Allows saved firing programs for reliable, repeatable results. |

| Calibration & Technician Skill | Requires accurate setup and expertise for optimal outcomes. |

Upgrade your dental lab with KINTEK's precision high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure your unique experimental needs for dental ceramics are met precisely. Contact us today to enhance your restoration quality and efficiency!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations