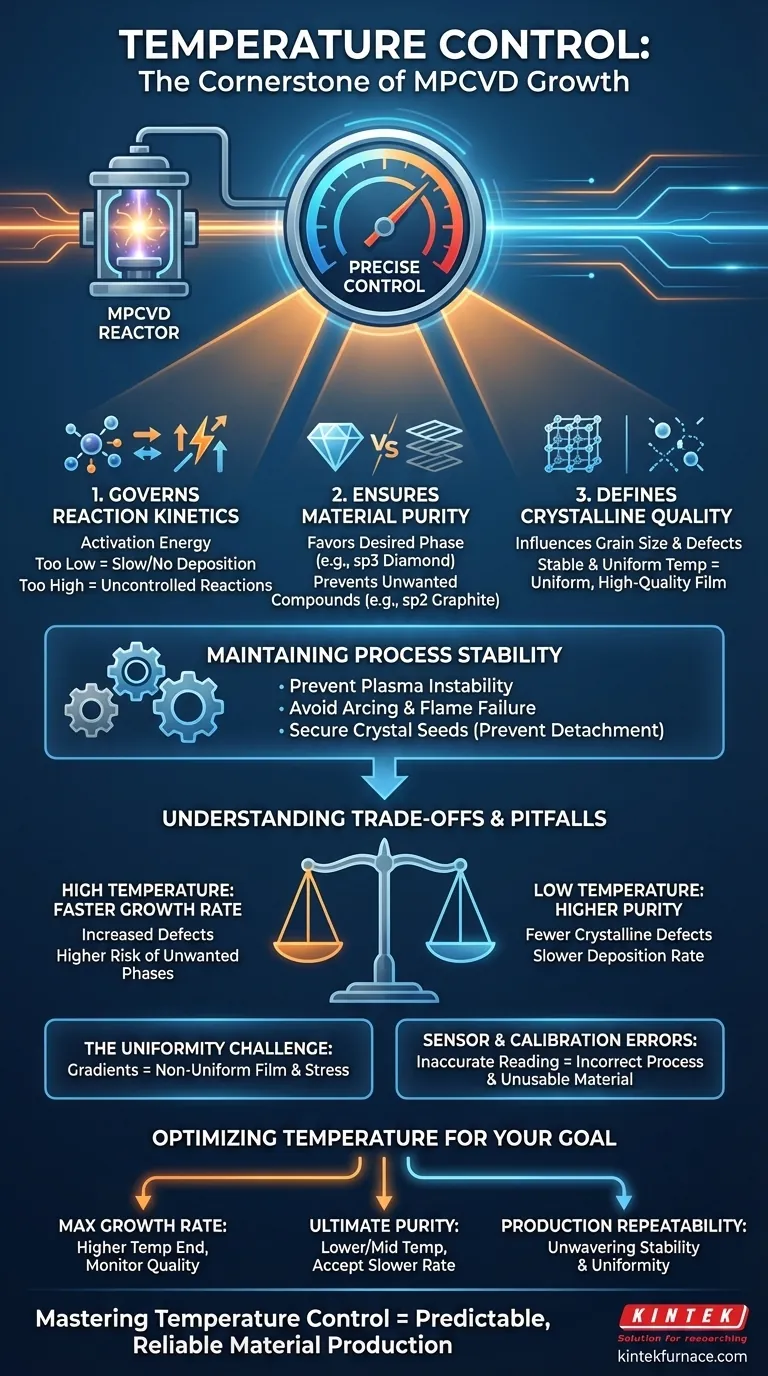

In MPCVD, precise temperature control is not just a parameter; it is the cornerstone of the entire growth process. It directly governs the speed and type of chemical reactions occurring in the plasma, which in turn dictates the purity, structure, and overall quality of the resulting material. Without rigorous temperature management, the process becomes unreliable, failing to produce the desired film and risking damage to the substrate or equipment.

Temperature in a Microwave Plasma Chemical Vapor Deposition (MPCVD) system is the primary lever for controlling chemical kinetics. Mismanage it, and you don't just get a poor-quality film—you risk creating entirely different, unwanted materials or causing a catastrophic process failure.

The Role of Temperature in Chemical Deposition

The final material is a direct product of the chemical environment. Temperature is the most critical variable you can control in that environment.

Governing Reaction Kinetics

The chemical reactions that allow precursor gases to break down and deposit onto a substrate require a specific amount of energy. Temperature provides this activation energy.

If the temperature is too low, the reaction rate will be impractically slow, or deposition may not occur at all. If it's too high, reactions can become uncontrolled.

Ensuring Material Purity

Precise temperature control ensures that only the desired chemical reactions take place. For diamond growth, this means favoring the formation of sp3-bonded carbon.

Incorrect temperatures can promote the creation of unwanted compounds or phases, such as sp2-bonded carbon (graphite), which severely degrades the final film's properties.

Defining Crystalline Quality

Temperature directly influences the final crystal structure, including grain size and defect density.

A stable and uniform temperature across the substrate promotes the growth of a uniform, high-quality crystalline film. Fluctuations lead to inconsistencies and imperfections.

Maintaining Process Stability and Reliability

Beyond the chemistry, temperature control is fundamental to the physical stability of the MPCVD process itself. The system's stability is directly tied to its thermal equilibrium.

Preventing Plasma Instability

In MPCVD, microwave power is used to generate and sustain the plasma, which heats the substrate. Stable temperature control requires smooth and continuous adjustments to this microwave power.

Erratic power adjustments to chase a fluctuating temperature can lead to an unstable plasma, compromising the entire growth run.

Avoiding Arcing and Flame Failure

One of the most severe consequences of poor temperature regulation is plasma arcing. This happens when the plasma becomes unstable and discharges uncontrollably.

An arc can extinguish the plasma (flame failure), immediately halting the deposition process and potentially damaging the substrate holder and chamber components.

Securing the Crystal Seeds

Successful growth begins with tiny crystal seeds on the substrate surface. The process is extremely sensitive in its initial stages.

Thermal shock from poor temperature control or an arcing event can cause these delicate seeds to detach from the substrate, resulting in a complete failure of the growth run.

Understanding the Trade-offs and Pitfalls

Optimizing temperature is not about finding one "perfect" number but managing a series of critical trade-offs.

The High-Temperature Dilemma

Operating at a higher temperature can significantly increase the material's growth rate.

However, this often comes at the cost of increased defect formation and a higher risk of producing unwanted material phases, thus reducing overall quality.

The Low-Temperature Limitation

Using a lower temperature generally results in higher-purity material with fewer crystalline defects.

The major drawback is a drastically slower deposition rate, which can make the process too slow and costly for many commercial or research applications.

The Uniformity Challenge

The absolute temperature at one point is less important than the temperature uniformity across the entire substrate.

Gradients—hot and cold spots on the substrate surface—will lead directly to non-uniform film thickness, stress, and inconsistent material properties.

Sensor and Calibration Errors

Your control system is only as reliable as its sensors. An inaccurate temperature reading from an uncalibrated or failing sensor renders the entire control loop useless.

This can lead to running the process at a completely incorrect temperature, producing unusable material without the operator even realizing there is a problem.

Optimizing Temperature for Your Goal

Your ideal temperature setpoint is a strategic choice dependent on your specific objective. Acknowledge the inherent trade-offs to make an informed decision.

- If your primary focus is maximum growth rate: You will likely operate at the higher end of the acceptable temperature range, but you must actively monitor for signs of reduced crystal quality.

- If your primary focus is ultimate material purity and quality: You should favor the lower-to-mid end of the temperature range, accepting a slower deposition rate as the trade-off for fewer defects.

- If your primary focus is process repeatability for production: Your goal is unwavering temperature stability and uniformity across the substrate, even more so than hitting a specific absolute number.

Ultimately, mastering temperature control is mastering the ability to produce your desired material predictably and reliably every time.

Summary Table:

| Temperature Control Aspect | Impact on MPCVD Process |

|---|---|

| Reaction Kinetics | Governs deposition rate and activation energy for reactions. |

| Material Purity | Prevents unwanted phases (e.g., graphite) and ensures sp3-bonded carbon. |

| Crystalline Quality | Influences grain size, defect density, and film uniformity. |

| Process Stability | Prevents plasma instability, arcing, and flame failure. |

| Growth Rate vs. Quality | Higher temperatures increase rate but may increase defects; lower temperatures favor purity but slow deposition. |

Struggling with inconsistent MPCVD results? Your process demands precision.

At KINTEK, we understand that reliable temperature control is the foundation of successful diamond film deposition. Leveraging our exceptional R&D and in-house manufacturing capabilities, we provide advanced high-temperature furnace solutions, including specialized CVD/PECVD systems, designed for unparalleled thermal stability and uniformity.

Our strong deep customization capability allows us to tailor a system that precisely meets your unique experimental requirements, whether your focus is on maximum growth rate, ultimate material purity, or production-scale repeatability.

Take control of your MPCVD process. Contact our experts today to discuss how a KINTEK solution can enhance your lab's reliability and output.

Visual Guide

Related Products

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What are the two main types of MPCVD based on microwave power and gas pressure? Unlock Optimal Diamond Growth

- Why is MPCVD considered environmentally friendly? A Guide to Sustainable Thin-Film Manufacturing

- What factors affect the quality of the diamond film produced by MPCVD? Master the 4 Key Parameters for Superior Growth

- What advantages does the MPCVD method have over the DC-PJ CVD method? Achieve Superior Diamond Synthesis

- What are the outstanding characteristics of diamond self-supporting films prepared by MPCVD? Unlock Unmatched Thermal, Electrical & Optical Performance

- How does MPCVD compare to other CVD techniques like HFCVD and PECVD? Discover the Best for High-Purity Films

- How is MPCVD used in manufacturing polycrystalline diamond optical components? Achieve Superior Optical Performance

- What does MPCVD stand for and what is its primary use? Discover High-Quality Diamond Growth Solutions