In short, MPCVD technology is considered versatile and important because it provides an unparalleled level of control and purity when synthesizing diamond. This precision allows engineers to unlock diamond's exceptional properties—such as extreme hardness, thermal conductivity, and biocompatibility—for a wide array of high-performance applications, from next-generation semiconductors to advanced medical implants.

The true value of MPCVD lies not just in its ability to create diamond, but in its unique capacity to create it cleanly and controllably. This process overcomes the limitations of other methods, making the theoretical potential of diamond a practical reality for critical industries.

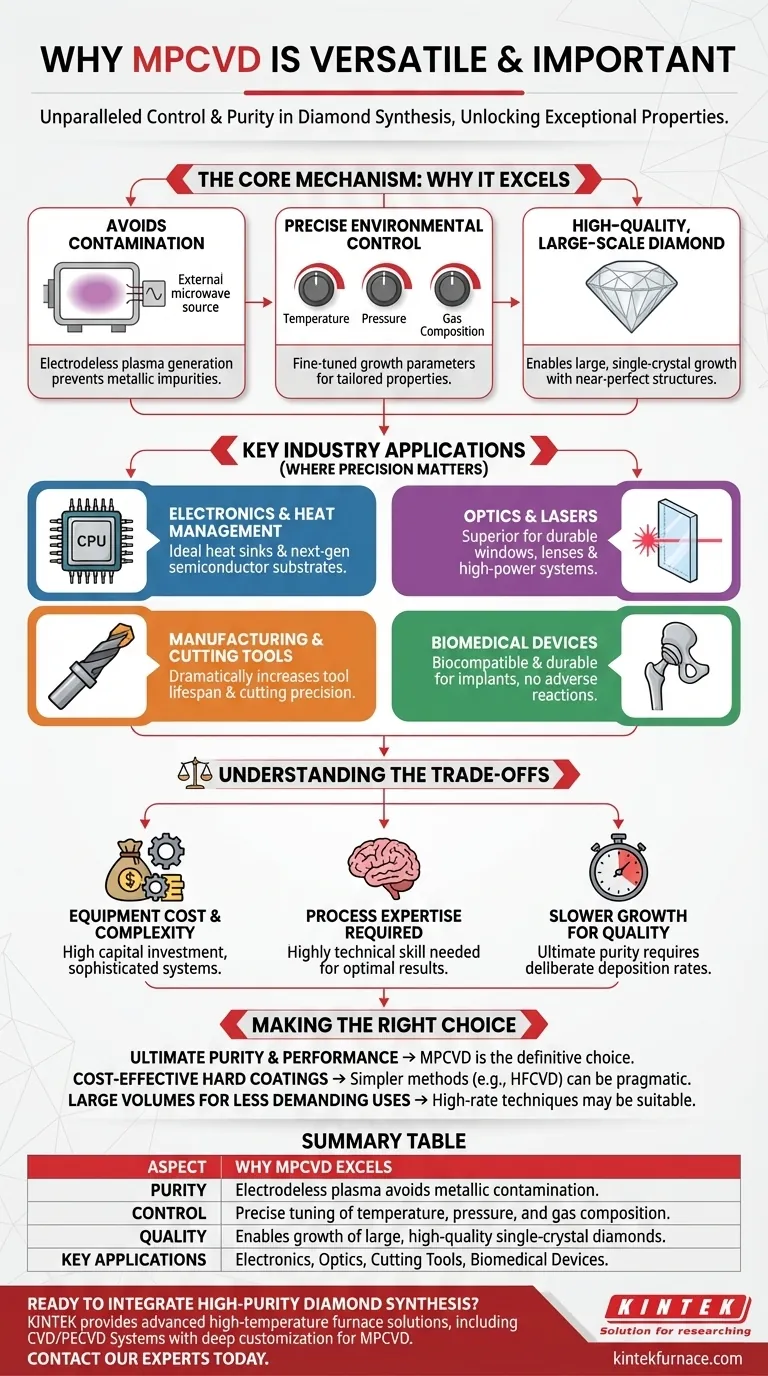

The Core Mechanism: Why MPCVD Excels

To understand MPCVD's versatility, you must first understand how it works. The method uses microwave energy to excite gases into a plasma state, providing an ideal environment for diamond crystal growth. This core mechanism gives it three fundamental advantages over other techniques.

It Avoids Contamination

Unlike other methods that use hot filaments or electrodes inside the reaction chamber, MPCVD (Microwave Plasma Chemical Vapor Deposition) generates its plasma using microwaves from an external source.

This "electrodeless" nature is critical. It eliminates a primary source of contamination, ensuring the resulting diamond film is exceptionally pure and free from unwanted metallic impurities that degrade performance.

It Offers Precise Environmental Control

MPCVD systems allow for fine-tuned control over all critical growth parameters: temperature, pressure, and gas composition.

This stable and highly controllable environment enables operators to tailor the diamond's properties for specific applications. Whether the goal is a perfectly clear optical window or a tough industrial coating, MPCVD provides the knobs to turn.

The Result: High-Quality, Large-Scale Diamond

The combination of a pure environment and precise control allows for the growth of large, single-crystal diamonds with near-perfect lattice structures.

This capability is essential for demanding applications like semiconductor wafers and high-power optics, where defects and grain boundaries would cripple device performance. MPCVD is the leading method for producing industrial-scale, high-quality diamond.

Where Precision Matters: Key Industry Applications

The high-quality diamond produced by MPCVD enhances performance and reliability across a spectrum of advanced fields.

Electronics and Heat Management

Diamond is the best thermal conductor known to man. MPCVD-grown diamond acts as an ideal heat sink for high-power electronics and CPUs, preventing overheating and improving reliability. Its electrical properties also make it a promising substrate for next-generation semiconductors.

Optics and Lasers

High-purity diamond is transparent across an incredibly broad range of light wavelengths, from ultraviolet to far-infrared. This makes it a superior material for durable windows, lenses, and components in high-power laser systems.

Manufacturing and Cutting Tools

By coating cutting tools and industrial drills with a thin layer of MPCVD diamond, their lifespan and performance can be dramatically increased. The coating provides a surface of extreme hardness and low friction, enabling faster and more precise machining of tough materials.

Biomedical Devices

Diamond is biocompatible and extremely durable. These properties make it an excellent material for medical implants, such as joint replacements or dental devices, as it does not corrode or trigger an adverse reaction from the body.

Understanding the Trade-offs

No technology is without its compromises. While MPCVD is superior in quality, it's important to understand its practical limitations.

Equipment Cost and Complexity

MPCVD systems are sophisticated and represent a significant capital investment. The microwave generators, vacuum chambers, and control systems are more complex and expensive than those used in simpler methods like Hot Filament CVD (HFCVD).

Slower Growth for Ultimate Quality

Achieving the highest crystal quality and purity often requires slower, more deliberate deposition rates. For applications where bulk is more important than perfection, other faster but "dirtier" methods may be more cost-effective.

Process Expertise Required

Operating an MPCVD system to its full potential requires significant process knowledge and expertise. It is not a "plug-and-play" technology; dialing in the correct parameters for a specific outcome is a highly technical skill.

Making the Right Choice for Your Goal

Your choice of diamond synthesis method depends entirely on the performance and cost requirements of your application.

- If your primary focus is ultimate purity and performance (e.g., semiconductor substrates, quantum sensors): MPCVD is the definitive and often only viable choice.

- If your primary focus is cost-effective hard coatings where some impurities are acceptable (e.g., some abrasive tools): Simpler methods like HFCVD can be a pragmatic alternative, though with a clear trade-off in quality.

- If your primary focus is producing large volumes of polycrystalline diamond for less demanding uses: Other high-rate deposition techniques might be more suitable, sacrificing crystal structure for speed.

Ultimately, MPCVD's importance stems from its unique ability to translate the remarkable theoretical properties of diamond into tangible, reliable, and high-performance technological solutions.

Summary Table:

| Aspect | Why MPCVD Excels |

|---|---|

| Purity | Electrodeless plasma avoids metallic contamination. |

| Control | Precise tuning of temperature, pressure, and gas composition. |

| Quality | Enables growth of large, high-quality single-crystal diamonds. |

| Key Applications | Electronics, Optics, Cutting Tools, Biomedical Devices. |

Ready to integrate high-purity diamond synthesis into your R&D or production?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements like MPCVD.

Contact our experts today to discuss how our MPCVD solutions can help you achieve unparalleled material performance.

Visual Guide

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- How does the MPCVD process work to deposit diamond? A Guide to High-Purity Synthesis

- What are the key advantages of the MPCVD method? Achieve Superior Material Purity and Scalability

- How can adjustments compensate for changes in MPCVD device parameters? Master Frequency and Phase Tuning for Stable Plasma

- What are the key components that need regular cleaning in MPCVD equipment? Ensure Optimal Performance and Longevity

- In which industries is the microwave plasma chemical vapor deposition system commonly used? Unlock High-Purity Material Synthesis

- How is MPCVD used in the production of polycrystalline diamond optical components? Discover High-Purity Diamond Growth for Optics

- Why is the MPCVD method considered the most promising for industrial diamond synthesis? Discover Its Unmatched Purity and Control

- What techniques are used to determine the quality of MPCVD-deposited films? A Guide to Comprehensive Characterization