Ultimately, Chemical Vapor Deposition (CVD) tube furnaces are not off-the-shelf products but highly modular systems. The primary customization options revolve around three core areas: the gas delivery system for controlling precursor chemicals, the vacuum system for managing the process environment, and the software for automating and monitoring the deposition process. These elements can be configured to suit the unique requirements of any given material synthesis project.

The key to a successful CVD process is not simply choosing a furnace, but engineering a complete system. Each customization, from the type of gas flow controller to the level of vacuum, is a critical variable that directly dictates the quality, uniformity, and properties of your final material.

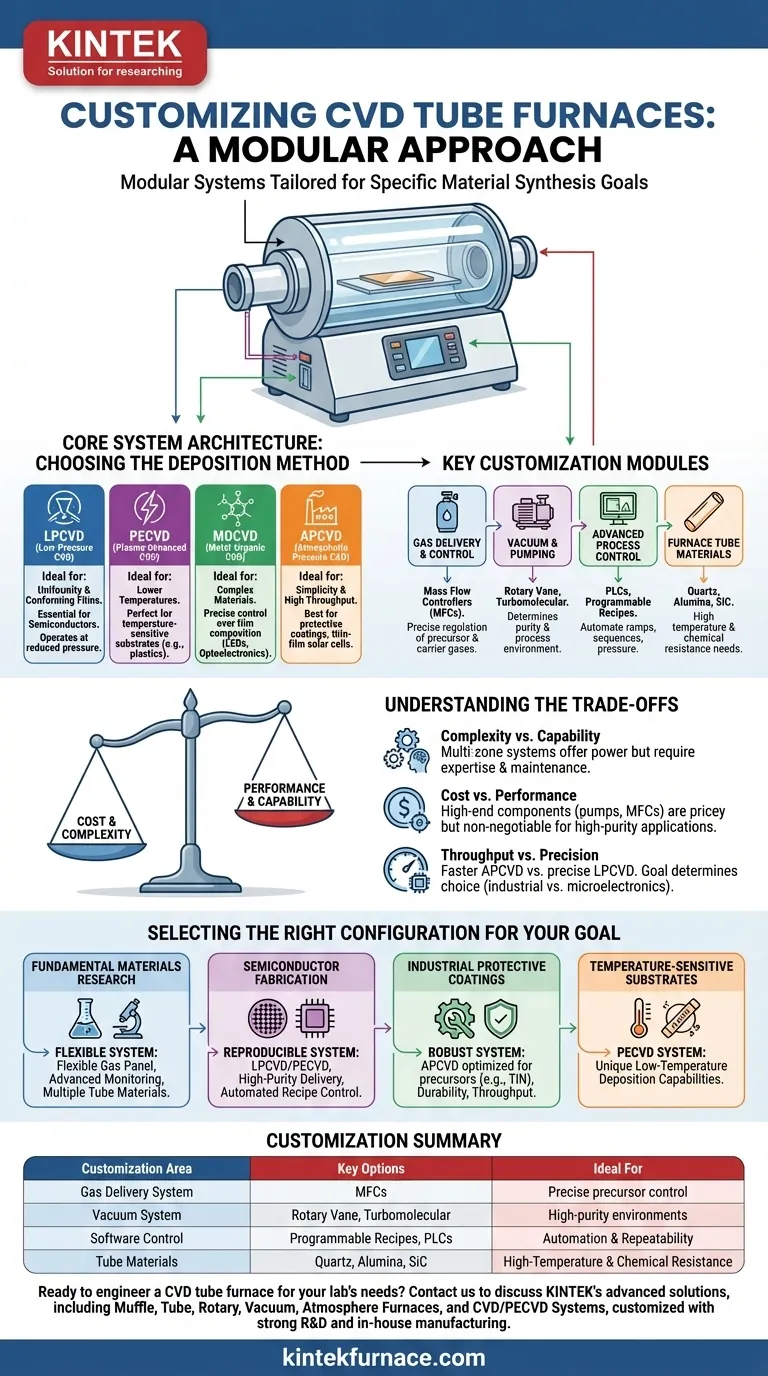

Core System Architecture: Choosing the Deposition Method

Before selecting individual components, your most fundamental choice is the type of CVD process you intend to run. This decision dictates the furnace's core design and operational parameters.

Low-Pressure CVD (LPCVD) for Uniformity

LPCVD operates at reduced pressure, which increases the mean free path of gas molecules. This results in highly uniform and conformal film deposition over complex surfaces, making it essential for semiconductor manufacturing.

Plasma-Enhanced CVD (PECVD) for Lower Temperatures

PECVD uses a plasma to energize the precursor gases, allowing deposition to occur at significantly lower temperatures than other CVD methods. This makes it ideal for depositing films on temperature-sensitive substrates, such as plastics or certain electronic components.

Metal-Organic CVD (MOCVD) for Complex Materials

MOCVD utilizes metal-organic compounds as precursors. This technique offers precise control over film composition and is the industry standard for manufacturing high-performance LEDs, laser diodes, and other optoelectronic devices.

Atmospheric Pressure CVD (APCVD) for Simplicity

Operating at standard atmospheric pressure, APCVD is a simpler, higher-throughput method. While film uniformity may be lower than LPCVD, it is highly effective for applications like depositing protective coatings or producing thin-film solar cells where scale is a priority.

Key Customization Modules

Once the core architecture is determined, you can tailor the system with specific modules to gain precise control over your process.

Gas Delivery and Control Systems

This is arguably the most critical area of customization. The gas cabinet and delivery lines are configured with mass flow controllers (MFCs) to precisely regulate the flow rate of each precursor, carrier, and purge gas. This control is essential for managing reaction stoichiometry and deposition rate.

Vacuum and Pumping Systems

The vacuum system determines the purity of your process environment. A basic rotary vane pump achieves low vacuum, suitable for some APCVD or LPCVD processes. For high-purity applications, this is combined with a turbomolecular or diffusion pump to achieve high vacuum, minimizing contamination from residual atmospheric gases.

Advanced Process Control

Modern CVD systems are equipped with programmable logic controllers (PLCs) and computer interfaces. This allows for programmable recipes that automate temperature ramps, gas flow sequences, and pressure changes, ensuring process repeatability and enabling the creation of complex, multi-layered material structures.

Furnace Chamber and Tube Materials

The process tube itself is a customizable component. Quartz is common for its high purity and transparency, but for very high temperatures or processes involving certain chemicals, materials like alumina or silicon carbide (SiC) are required for their superior thermal stability and chemical resistance.

Understanding the Trade-offs

Customizing a CVD system is a balancing act. Each decision involves trade-offs that impact cost, complexity, and capability.

Complexity vs. Capability

A multi-zone furnace with an advanced PECVD generator and a high-purity MOCVD gas cabinet offers immense capability. However, it also requires significant operator expertise, rigorous maintenance, and complex safety protocols.

Cost vs. Performance

High-end components directly impact price. A high-vacuum turbomolecular pump and high-precision mass flow controllers can cost many times more than their basic counterparts but are non-negotiable for achieving the purity and uniformity required in semiconductor or R&D applications.

Throughput vs. Precision

An APCVD system may process wafers faster, but an LPCVD system will deliver the superior film conformity needed for microelectronics. The right choice depends entirely on whether your goal is industrial scale or device-level precision.

Selecting the Right Configuration for Your Goal

Your application should be the sole driver of your customization choices.

- If your primary focus is fundamental materials research: Prioritize a flexible gas panel, advanced process monitoring, and compatibility with multiple process tube materials.

- If your primary focus is semiconductor device fabrication: An LPCVD or PECVD system with high-purity gas delivery and fully automated recipe control is essential for reproducibility.

- If your primary focus is applying industrial protective coatings: A robust APCVD system optimized for specific precursors like titanium nitride (TiN) with an emphasis on durability and throughput is the most practical choice.

- If your primary focus is working with temperature-sensitive substrates: A Plasma-Enhanced CVD (PECVD) system is the only viable option due to its unique low-temperature deposition capabilities.

Ultimately, a well-configured CVD furnace becomes a precise instrument engineered to meet your specific material synthesis goals.

Summary Table:

| Customization Area | Key Options | Ideal For |

|---|---|---|

| Gas Delivery System | Mass Flow Controllers (MFCs) | Precise precursor control for stoichiometry |

| Vacuum System | Rotary vane, turbomolecular pumps | High-purity environments in LPCVD/PECVD |

| Software Control | Programmable recipes, PLCs | Automation and repeatability in complex processes |

| Tube Materials | Quartz, alumina, silicon carbide | High-temperature and chemical resistance needs |

Ready to engineer a CVD tube furnace that perfectly fits your lab's needs? Contact us today to discuss how KINTEK's advanced high-temperature furnace solutions—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—can be customized with our strong R&D and in-house manufacturing capabilities. We'll help you achieve precise control, improved efficiency, and superior material synthesis outcomes tailored to your unique experimental requirements.

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- How does the gas control system in a CVD tube furnace enhance its functionality? Achieve Precise Thin Film Deposition

- How are hexagonal boron nitride (h-BN) films processed using CVD tube furnaces? Optimize Growth for High-Quality 2D Materials

- What temperature range do standard CVD tube furnaces operate at? Unlock Precision for Your Material Deposition

- What is a common subtype of CVD furnace and how does it function? Discover the CVD Tube Furnace for Uniform Thin Films

- How can integrating CVD tube furnaces with other technologies benefit device fabrication? Unlock Advanced Hybrid Processes