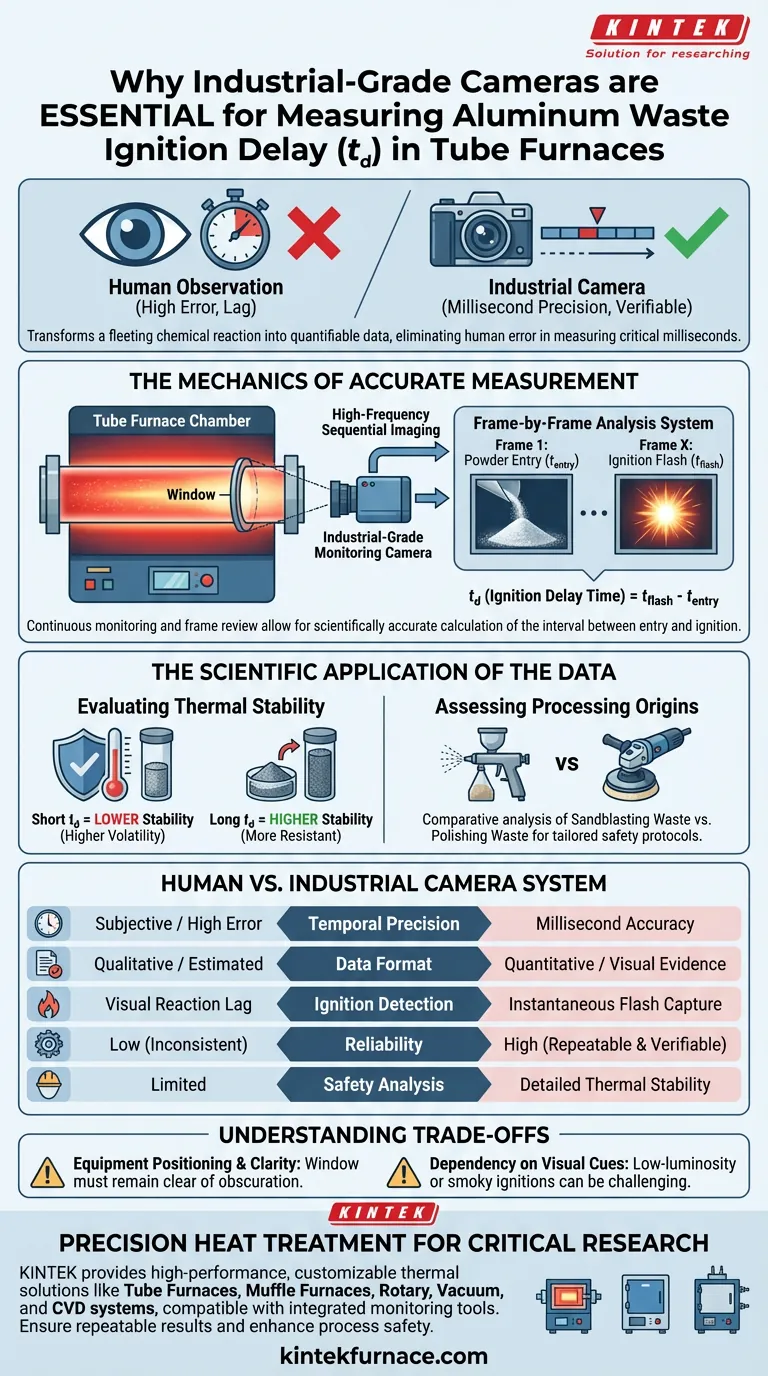

An industrial-grade monitoring camera system provides the necessary temporal precision to capture rapid combustion events that human observation cannot reliably track. By recording real-time sequential images through the furnace observation window, the system documents the exact interval between the aluminum powder's entry and its ignition flash, allowing for a scientifically accurate calculation of ignition delay time ($t_d$).

The camera system transforms a fleeting chemical reaction into quantifiable data, enabling the precise evaluation of thermal stability in volatile aluminum waste. It eliminates human error in measuring the critical milliseconds between heat exposure and combustion.

The Mechanics of Accurate Measurement

Real-Time Sequential Imaging

The primary function of the camera system is to capture a high-frequency series of images. Installed outside the observation window, it continuously monitors the interior of the high-temperature furnace chamber.

This setup allows researchers to review the footage frame-by-frame. It converts a fast-moving physical event into a static, analyzeable timeline.

Calculating Ignition Delay Time ($t_d$)

To determine the ignition delay time, the system establishes two critical data points. The first is the exact moment the aluminum powder sample enters the furnace environment.

The second data point is the first appearance of a combustion flash. The time elapsed between these two specific frames constitutes the accurate $t_d$.

Overcoming Human Limitations

Combustion of fine powders can occur in split seconds. Relying on the naked eye and a manual stopwatch introduces significant reaction-time errors.

An industrial camera removes this variable. It ensures that the calculated delay is based on objective visual evidence rather than subjective perception.

The Scientific Application of the Data

Evaluating Thermal Stability

The data collected is not just about timing; it is a direct proxy for safety and stability. The ignition delay time serves as a key metric for scientifically evaluating the thermal stability of the waste powder.

A shorter delay typically indicates lower stability and higher volatility. A longer delay suggests the material is more resistant to immediate combustion under thermal stress.

Assessing Different Processing Origins

Aluminum waste varies significantly depending on how it was generated. The monitoring system allows for comparative analysis of powders originating from different industrial processes.

Specifically, it helps characterize waste from sandblasting or polishing operations. By isolating the ignition characteristics of each type, researchers can develop safer handling protocols specific to the waste source.

Understanding the Trade-offs

Equipment Positioning and Clarity

While high-precision cameras offer superior data, they are limited by their view of the reaction. The camera must be positioned outside the observation window to survive the heat, which introduces a potential point of failure if the window becomes obscured.

Dependency on Visual Cues

The system relies entirely on optical detection of the "flash." In scenarios with low-luminosity ignition or heavy smoke generation prior to ignition, the precise start of combustion can be difficult to pinpoint even with industrial imaging.

Maximizing Research Accuracy

To ensure your experimental setup yields valid data regarding aluminum waste safety, consider the following technical priorities:

- If your primary focus is Waste Characterization: Ensure your imaging system is calibrated to distinguish between the subtle visual signatures of sandblasting versus polishing waste.

- If your primary focus is Process Safety: Prioritize high frame-rate capture to identify the absolute minimum ignition delay time, as this represents the "worst-case" scenario for volatility.

Accurate measurement of ignition delay is the foundational step in converting hazardous industrial waste into a managed risk.

Summary Table:

| Feature | Human Observation | Industrial Camera System |

|---|---|---|

| Temporal Precision | Subjective / High Margin of Error | Millisecond Accuracy / Frame-by-Frame |

| Data Format | Qualitative / Estimated | Quantitative / Visual Evidence |

| Ignition Detection | Visual Reaction Time Lag | Instantaneous Flash Capture |

| Reliability | Low (Inconsistent) | High (Repeatable & Verifiable) |

| Safety Analysis | Limited | Detailed Thermal Stability Evaluation |

Precision Heat Treatment for Your Critical Research

Accurate data starts with the right equipment. KINTEK provides high-performance, industrial-grade thermal solutions designed for the most demanding laboratory environments. Backed by expert R&D and manufacturing, we offer high-precision Tube Furnaces, Muffle Furnaces, Rotary, Vacuum, and CVD systems—all fully customizable to accommodate integrated monitoring tools like high-speed imaging windows.

Whether you are analyzing the volatility of sandblasting waste or characterising polishing powders, our systems ensure the stability and control you need for repeatable results. Contact KINTEK today to discuss your unique project requirements and see how our advanced furnace technology can enhance your process safety and data accuracy.

Visual Guide

References

- Roya Biabani, Mentore Vaccari. Thermal pre-treatment of reactive aluminium alloy waste powders. DOI: 10.1007/s10163-024-01904-y

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role does a high-temperature tube furnace play in N-CP synthesis? Mastering Precision Carbonization

- How do tube furnaces provide precise and uniform heating? Unlock Consistent Thermal Processing

- What is a Quartz Tube Furnace and what is its primary function? Essential for Real-Time Material Observation

- What role does a horizontal tube furnace play in the carbonization of ionic liquid precursors? Master Thermal Control

- What is the primary role of a tube furnace in the evaluation of cable material smoke acidity? Achieve Precise Testing

- What role do industrial tube furnaces play in the oxidation of NiCrAl alloys? Precise Stability for Reliable Data

- What are the key factors affecting temperature control in split tube furnaces? Ensure Precision and Uniformity

- What makes a lab tube furnace a versatile tool in material science and engineering? Unlock Precise Material Control