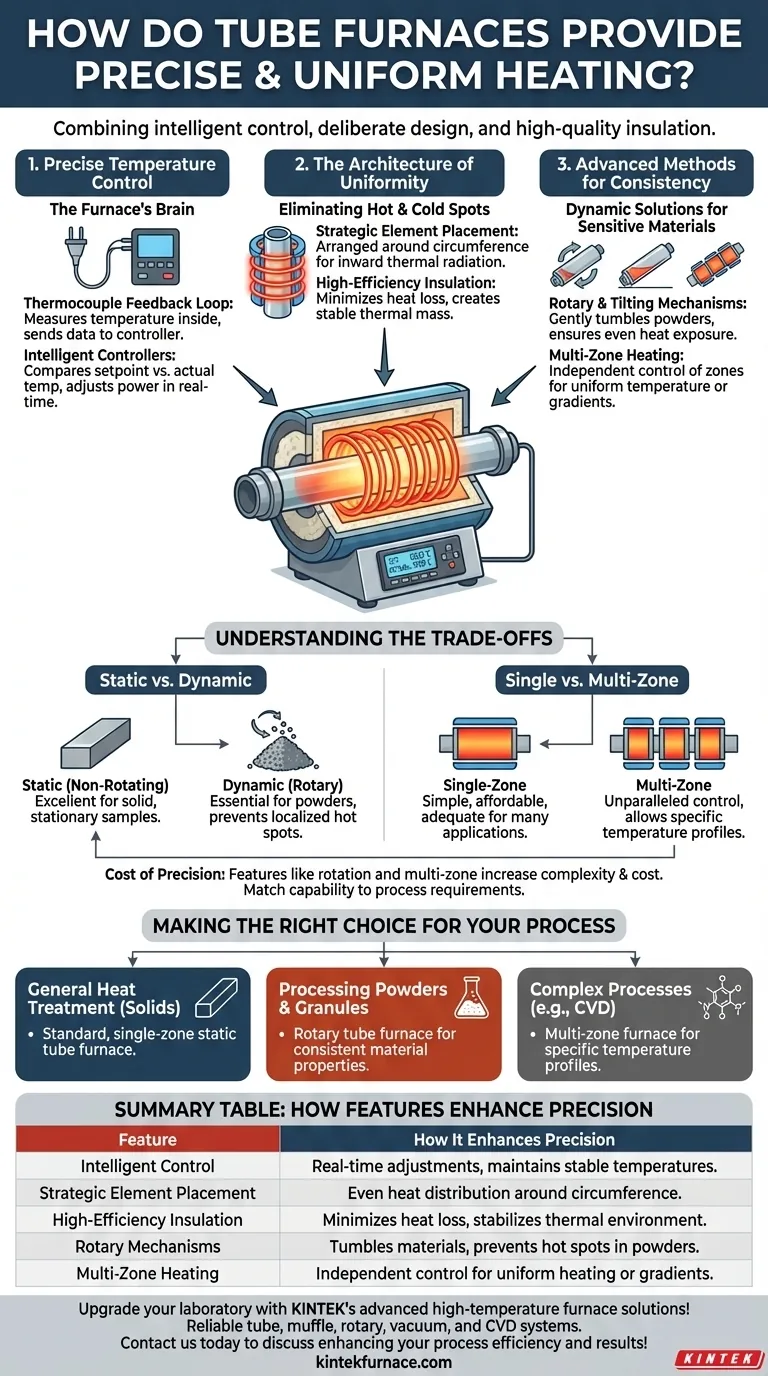

At their core, tube furnaces provide precise and uniform heating by combining three critical elements: an intelligent temperature control system, a deliberate physical design that distributes heat evenly, and high-quality insulation that prevents heat loss. For applications demanding the highest level of consistency, some furnaces also employ mechanical rotation or tilting to ensure the material inside is heated from all angles.

The key to a tube furnace's performance is not a single feature, but a holistic system. Uniform heating is the result of a constant conversation between a temperature sensor, a controller that adjusts power, and a physical design built to retain and distribute that energy perfectly.

The Foundation: Precise Temperature Control

True precision begins with a system that can measure and react to temperature changes in real time. This is the furnace's "brain," ensuring the set temperature is the actual temperature.

The Thermocouple Feedback Loop

A thermocouple, a highly sensitive temperature sensor, is placed inside or near the heating chamber.

It constantly measures the temperature and sends this data back to a central controller. This creates a closed-loop system where the furnace is always aware of its own internal state.

Intelligent Controllers

The controller is the decision-maker. It compares the real-time temperature from the thermocouple to the desired temperature you've set (the setpoint).

If the temperature is too low, the controller increases power to the heating elements. If it's too high, it reduces or cuts the power. This constant adjustment, happening many times per second, maintains a stable thermal environment.

The Architecture of Uniformity

A smart controller is useless if the furnace's physical body can't distribute the heat properly. The furnace's architecture is designed specifically to eliminate hot and cold spots.

Strategic Element Placement

Heating elements are not placed randomly. They are carefully arranged around the circumference of the furnace tube.

This design ensures that thermal energy radiates inward from all sides, enveloping the sample in a consistent field of heat.

High-Efficiency Insulation

High-grade thermal insulation is packed around the heating chamber. This material is critical for two reasons.

First, it minimizes heat loss to the outside environment, which improves energy efficiency. Second, and more importantly, it traps the heat inside, creating a stable, uniform thermal mass that resists temperature fluctuations.

Advanced Methods for Maximum Consistency

For the most sensitive materials or processes like chemical vapor deposition (CVD) and sintering powders, standard heating isn't enough. Advanced furnaces use dynamic methods to achieve near-perfect uniformity.

Rotary Tube Furnaces

In a rotary furnace, the central tube itself rotates continuously.

This motion causes the material inside, such as powders or granules, to gently tumble and flip. This guarantees that every particle is exposed to the same amount of heat, preventing any part of the sample from being underheated or overheated.

Tilting Mechanisms

Some rotary furnaces can also be tilted at an angle.

This feature uses gravity to help move the material through the tube, ensuring a consistent flow and uniform heating from one end to the other.

Multi-Zone Heating

The most advanced furnaces divide the tube length into multiple, independently controlled heating zones.

Each zone has its own heating elements and thermocouple. This allows you to either maintain an extremely uniform temperature along the entire length of the tube or intentionally create a precise temperature gradient for complex processes.

Understanding the Trade-offs

Achieving perfect uniformity involves balancing complexity, application, and cost. Not every process requires the most advanced system.

Static vs. Dynamic Furnaces

A static (non-rotating) tube furnace is excellent for heating solid, stationary samples. However, for powders or materials that can agglomerate, a dynamic rotary furnace is far superior as it prevents localized hot spots.

Single-Zone vs. Multi-Zone

A single-zone furnace is simpler, more affordable, and perfectly adequate for many applications. A multi-zone furnace offers unparalleled control but comes with increased complexity and cost. It is only necessary for processes that require a specific temperature profile along the tube's length.

The Cost of Precision

As features like rotation, tilting, and multiple heating zones are added, the cost and complexity of the furnace increase significantly. The goal is to match the furnace's capability to the actual requirements of your process, not to over-invest in precision you don't need.

Making the Right Choice for Your Process

Your specific application dictates the type of furnace you need.

- If your primary focus is general heat treatment of solid samples: A standard, single-zone static tube furnace with good insulation will deliver reliable results.

- If your primary focus is processing powders, granules, or materials prone to uneven heating: A rotary tube furnace is essential for achieving consistent material properties.

- If your primary focus is a complex process requiring a specific temperature profile (like CVD): A multi-zone furnace is the only way to achieve the necessary level of control.

Ultimately, a tube furnace's precision comes from a system where intelligent control and thoughtful design work together to create an ideal thermal environment.

Summary Table:

| Feature | How It Enhances Precision and Uniformity |

|---|---|

| Intelligent Temperature Control | Uses thermocouples and controllers for real-time adjustments, maintaining stable temperatures. |

| Strategic Element Placement | Heating elements arranged around the tube circumference ensure even heat distribution. |

| High-Efficiency Insulation | Minimizes heat loss and stabilizes the thermal environment for consistency. |

| Rotary Mechanisms | Rotates or tilts the tube to tumble materials, preventing hot spots in powders or granules. |

| Multi-Zone Heating | Independent control of zones allows for uniform heating or custom temperature gradients. |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable tube furnaces, muffle furnaces, rotary furnaces, vacuum & atmosphere furnaces, and CVD/PECVD systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for precise and uniform heating. Contact us today to discuss how our solutions can enhance your process efficiency and results!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What advantages do multi zone tube furnaces offer for chemical reaction studies? Achieve Precise Thermal Control

- What safety precautions should be followed when operating a multi zone tube furnace? Ensure Safe and Efficient Lab Operations

- How does a multi-zone tube furnace achieve precise temperature gradient control? Master MoS2 Isotope Monolayer Synthesis

- How are multi zone tube furnaces applied in biomedical research? Unlock Advanced Biomaterial Engineering

- What steps are involved in the installation of a multi zone tube furnace? Ensure Precision and Safety for Your Lab