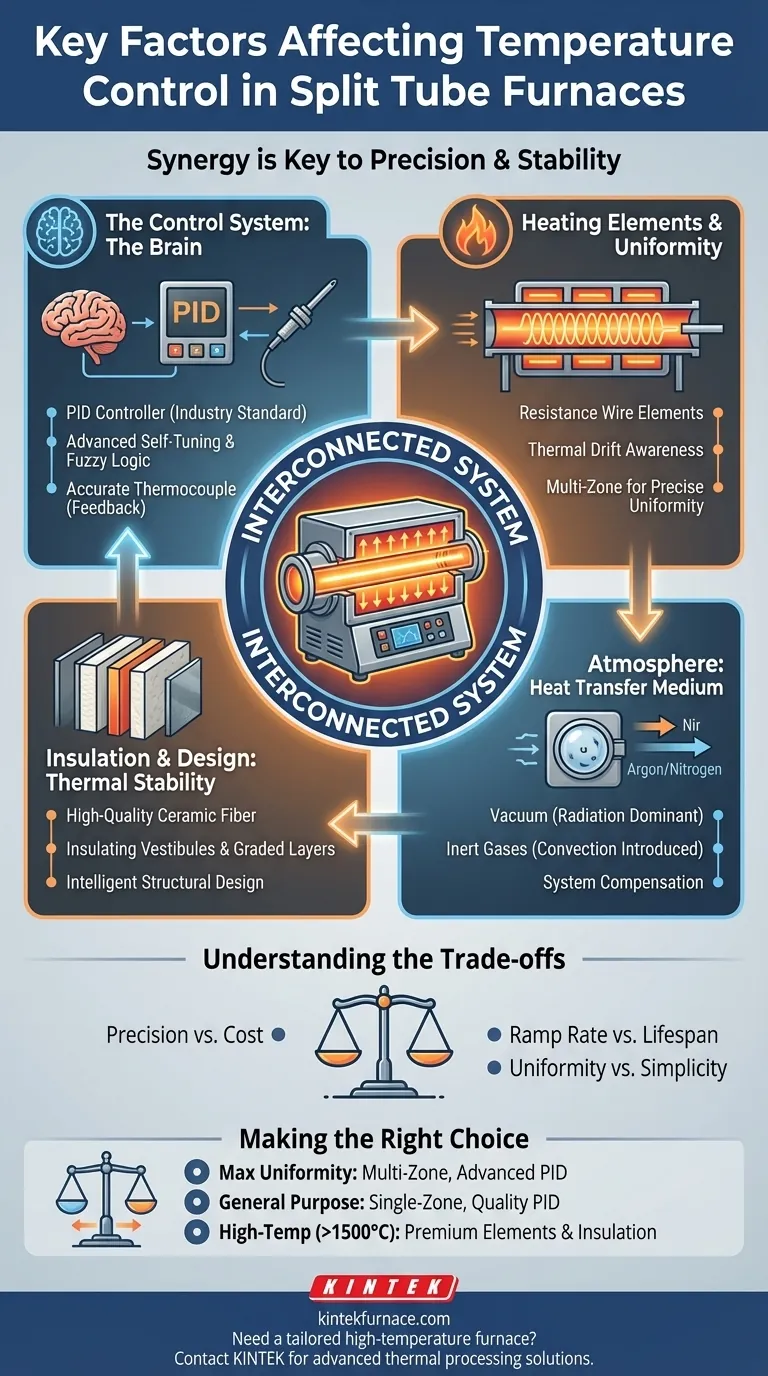

Achieving precise temperature control in a split tube furnace is not about a single component, but the synergy between its core systems. The most critical factors are the sophistication of the temperature control system (like PID), the type and condition of the heating elements, the quality of the thermal insulation, and the furnace's physical design, including multi-zone capabilities.

The accuracy and stability of your furnace are a direct result of how its control system, heating elements, and insulation work together. Understanding these as an interconnected system is the key to achieving consistent, repeatable thermal processing for any application.

The Control System: The Brain of the Operation

The temperature controller is the active component responsible for executing your desired heating profile. Its intelligence and responsiveness are paramount for accuracy.

PID Controllers: The Industry Standard

A Proportional-Integral-Derivative (PID) controller is the foundation of modern furnace control. It continuously measures the chamber temperature via a thermocouple and intelligently adjusts the power sent to the heating elements to minimize the difference between the setpoint and the actual temperature.

Advanced Regulation and Self-Tuning

More advanced systems incorporate fuzzy logic and self-tuning technologies. These features allow the furnace to "learn" its own thermal characteristics, automatically optimizing the PID parameters to prevent temperature overshoots and improve stability during ramps and soaks.

The Role of the Thermocouple

The controller is only as good as the information it receives. A thermocouple acts as the furnace's nerve ending, providing the real-time temperature feedback. Any drift or inaccuracy in the thermocouple will lead to a direct error in the chamber's temperature, even with a perfect controller.

Heating Elements and Uniformity

The heating elements are the source of thermal energy. Their design and configuration directly influence the temperature's stability and distribution.

Element Type and Thermal Drift

Most split tube furnaces use resistance wire heating elements. Over time and with repeated thermal cycling, these elements can experience thermal drift, where their electrical resistance changes. This can cause the furnace to heat differently over its lifespan, requiring recalibration.

Multi-Zone Designs for Precise Uniformity

For applications demanding the highest level of uniformity, multi-zone furnaces are the solution. These models divide the heating chamber into multiple sections, each with its own heating elements and control thermocouple. This allows the system to independently manage temperatures along the length of the tube, correcting for natural heat loss at the ends and creating a larger, more uniform hot zone.

Insulation and Design: Preserving Thermal Stability

A furnace's ability to hold a stable temperature depends heavily on its ability to prevent heat from escaping. This is the primary role of insulation and intelligent structural design.

The Importance of High-Quality Insulation

Layers of high-purity ceramic fiber insulation are used to line the furnace chamber. This material minimizes heat loss, which not only improves energy efficiency but also makes it easier for the controller to maintain a stable temperature by reducing the influence of the ambient environment.

Structural Design: Vestibules and Graded Layers

Well-designed furnaces incorporate insulating vestibules at either end of the process tube. These act as thermal buffers, drastically reducing heat loss from the openings. The use of graded insulation layers—with different types of insulation optimized for different temperature ranges—further enhances thermal efficiency, especially in high-temperature models.

The Impact of Atmosphere

The atmosphere inside the process tube affects heat transfer. A vacuum environment eliminates convection, meaning heat transfers primarily through radiation. Conversely, an atmosphere of argon or nitrogen introduces convection. The control system must be able to compensate for these different modes of heat transfer to maintain stability.

Understanding the Trade-offs

Choosing or operating a furnace involves balancing competing priorities. Being aware of these trade-offs is crucial for making informed decisions.

Control Precision vs. Cost

A multi-zone furnace with a self-tuning PID controller offers superior uniformity and precision. However, this complexity comes at a significantly higher cost than a standard single-zone furnace.

Ramp Rate vs. Element Lifespan

Aggressive ramp rates (heating up very quickly) place significant stress on the heating elements. While sometimes necessary, frequent rapid heating can shorten the operational life of the elements and accelerate thermal drift.

Uniformity vs. Simplicity

A single-zone furnace is simple to operate and maintain. However, it will inherently have a shorter uniform hot zone compared to a multi-zone furnace, which can actively compensate for heat loss at the ends of the tube.

Making the Right Choice for Your Process

Your specific application determines which factors are most important. Use your primary goal to guide your focus.

- If your primary focus is maximum uniformity for sensitive materials: Prioritize a multi-zone furnace with an advanced, self-tuning PID controller to create the largest and most stable hot zone.

- If your primary focus is general-purpose heating on a budget: A single-zone furnace with a quality PID controller and robust ceramic fiber insulation is a reliable and effective choice.

- If your primary focus is high-temperature processing (>1500°C): Pay close attention to the heating element material and the quality of the graded insulation and end vestibules, as managing heat loss is the dominant challenge.

By understanding these factors as an integrated system, you can ensure your furnace delivers the precise and repeatable results your work demands.

Summary Table:

| Factor | Key Components | Impact on Temperature Control |

|---|---|---|

| Control System | PID controllers, thermocouples, self-tuning | Ensures accuracy and stability during heating profiles |

| Heating Elements | Resistance wires, multi-zone designs | Affects thermal uniformity and drift over time |

| Insulation & Design | Ceramic fiber, vestibules, graded layers | Reduces heat loss and maintains thermal stability |

| Atmosphere | Vacuum, argon, nitrogen | Alters heat transfer modes, requiring system compensation |

Need a high-temperature furnace tailored to your lab's unique needs? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise temperature control and uniformity for your experiments. Contact us today to discuss how we can enhance your thermal processing with reliable, efficient equipment!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation