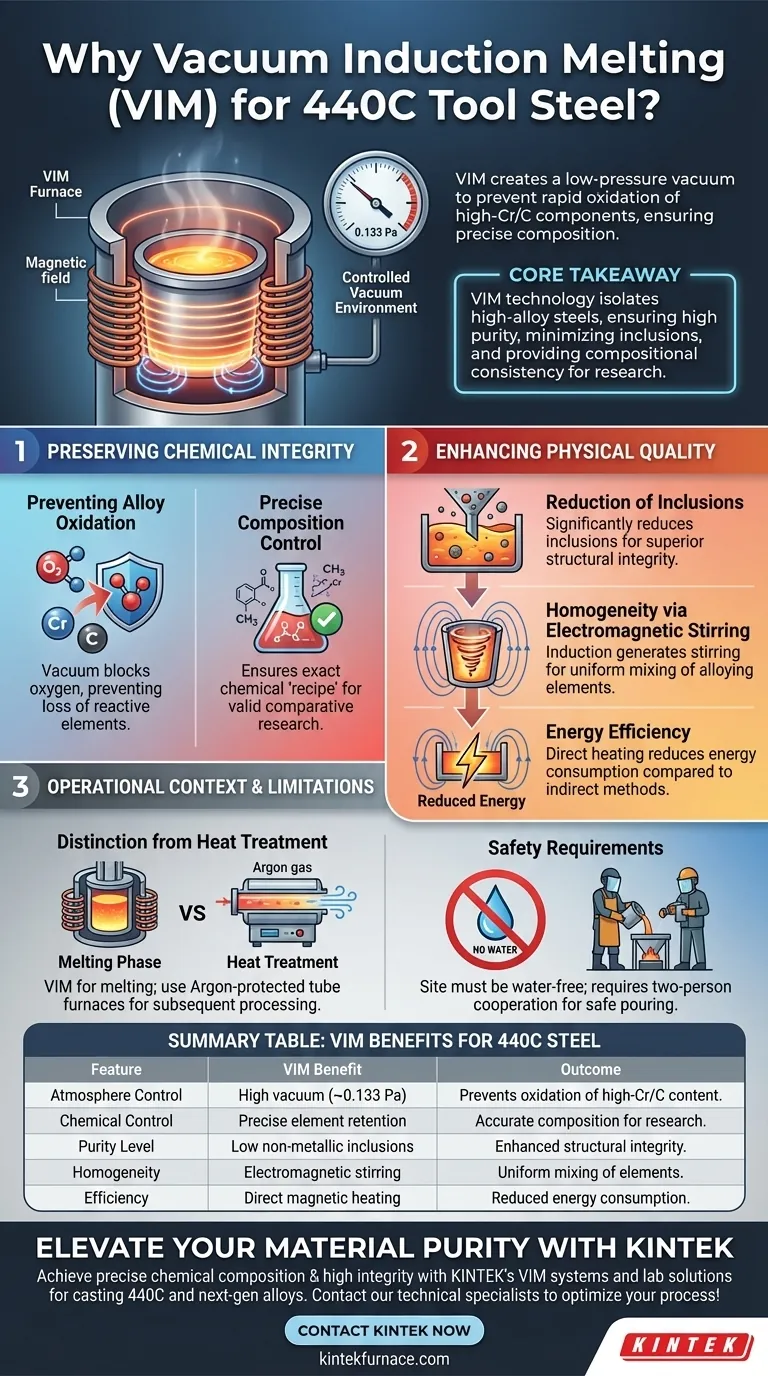

Vacuum Induction Melting (VIM) is utilized for 440C tool steel primarily to create a controlled low-pressure vacuum environment, typically around 0.133 Pa. This specific atmosphere prevents the rapid oxidation of the alloy's high-chromium and high-carbon components, ensuring the final cast retains the precise chemical composition required for high-performance applications.

Core Takeaway VIM technology solves the challenge of melting reactive high-alloy steels by isolating them from atmospheric contamination. This ensures high purity, minimizes inclusions, and provides the compositional consistency necessary for accurate comparative research.

Preserving Chemical Integrity

Preventing Alloy Oxidation

440C tool steel is defined by its high-chromium and high-carbon content. These elements are highly reactive to oxygen at melting temperatures.

A VIM furnace utilizes a vacuum environment to effectively block oxygen from the melt. This prevents the loss of these critical alloying elements through oxidation.

Precise Composition Control

For research and high-quality manufacturing, the chemical "recipe" of the steel must be exact.

The vacuum environment allows for precise control over the chemical composition. This ensures that the cast samples match the theoretical specifications required for valid comparative research.

Enhancing Physical Quality

Reduction of Inclusions

Impurities and non-metallic inclusions can severely degrade the strength and performance of tool steel.

VIM significantly reduces the formation of inclusions compared to open-air melting methods. This results in high-purity cast samples with superior structural integrity.

Homogeneity via Electromagnetic Stirring

Achieving a uniform mix of elements is critical when dealing with heavy or complex alloys.

The induction process inherently generates electromagnetic stirring within the molten metal. This ensures raw materials are thoroughly mixed and alloyed in the molten state, producing a uniform chemical composition.

Energy Efficiency

Beyond quality, VIM offers distinct operational advantages regarding energy usage.

The magnetic field generated by the furnace heats the metal directly. This offers reduced energy consumption due to efficient energy transfer compared to indirect methods like arc or resistance heating.

Operational Context and Limitations

Distinction from Heat Treatment

While VIM is essential for the melting phase, it is not used for subsequent thermal processing.

For processes like austenitizing at 1050 °C, a tube furnace with flowing argon protection is utilized. This inert atmosphere prevents surface decarburization and high-temperature oxidation after the steel has solidified.

Safety Requirements

The pouring process in a VIM setup requires strict adherence to safety protocols.

The site must be completely free from water and obstacles to prevent dangerous reactions. Additionally, operations generally require the cooperation of a second person to ensure safe handling and disposal of molten material.

Making the Right Choice for Your Goal

When evaluating the preparation of 440C tool steel, consider your specific constraints:

- If your primary focus is Research Accuracy: Prioritize VIM to ensure high-purity samples with precise chemical compositions and minimal inclusions.

- If your primary focus is Process Efficiency: Leverage the direct magnetic heating of induction technology to lower energy consumption compared to resistance heating.

- If your primary focus is Surface Integrity: Remember that VIM protects the bulk melt, but you must switch to Argon-protected environments for subsequent heat treatments to prevent decarburization.

By utilizing VIM, you ensure the foundational quality of the steel is preserved from the very first step of the casting process.

Summary Table:

| Feature | VIM Benefit for 440C Steel | Outcome |

|---|---|---|

| Atmosphere Control | High vacuum (~0.133 Pa) | Prevents oxidation of high-chromium/carbon content |

| Chemical Control | Precise element retention | Accurate composition for research and manufacturing |

| Purity Level | Low non-metallic inclusions | Enhanced structural integrity and mechanical strength |

| Homogeneity | Electromagnetic stirring | Uniform mixing of alloying elements in the melt |

| Efficiency | Direct magnetic heating | Reduced energy consumption compared to indirect methods |

Elevate Your Material Purity with KINTEK

Ready to achieve the precise chemical composition and high structural integrity required for your research and production? Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum Induction Melting (VIM) systems, Tube furnaces, and customizable high-temp lab solutions tailored to your unique metallurgy needs. Whether you are casting 440C tool steel or developing next-generation alloys, our systems provide the control and consistency you demand.

Contact our technical specialists today to discuss your custom furnace requirements and optimize your casting process!

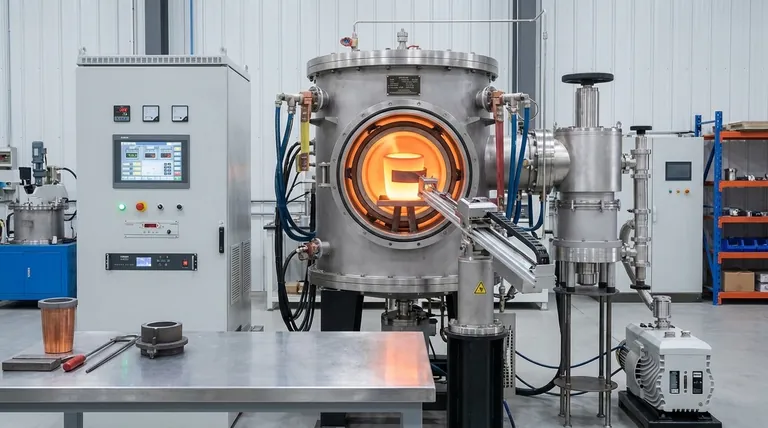

Visual Guide

References

- Vania Rodríguez Herrejon, Venkata Karthik Nadimpalli. Comparative Analysis of Wear Properties of 440C Tool Steel Fabricated by Spray Forming and Conventional Casting. DOI: 10.1007/s11665-025-11860-9

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Why are graphene induction coils able to maintain more stable heating rates? Achieve Precision at 2000°C+

- Why is precise temperature control in an electric melting furnace essential for AZ91D/Si3N4/WGP composites?

- Why is excess Lanthanum required in La(Fe,Si)13 alloy melting? Overcome Burn-off for Peak Magnetocaloric Performance

- Which precious metals can be smelted using induction furnaces? Unlock High Purity and Efficiency

- What is an IGBT induction melting furnace? Achieve Faster, Cleaner, and More Efficient Metal Melting

- Why is a cooling system necessary in an induction heater? Prevent Overheating and Ensure Safe Operation

- Why is repeated flipping and remelting necessary when producing Sm-Co-Fe alloy ingots in an arc furnace? Key Insights

- How do induction furnaces contribute to cost savings in the long term? Unlock Long-Term Efficiency and ROI