Virtually all precious metals can be smelted using induction furnaces. This includes common metals like gold and silver, as well as the entire platinum group: platinum, iridium, rhodium, palladium, osmium, and ruthenium. The technology's precise control and clean heating mechanism make it the standard for processing high-value materials where purity is paramount.

The question is not whether an induction furnace can smelt a precious metal, but rather what type of induction system is required. While standard furnaces work for gold and silver, high-temperature and reactive metals like platinum or rhodium demand specialized vacuum or controlled-atmosphere induction systems to prevent contamination.

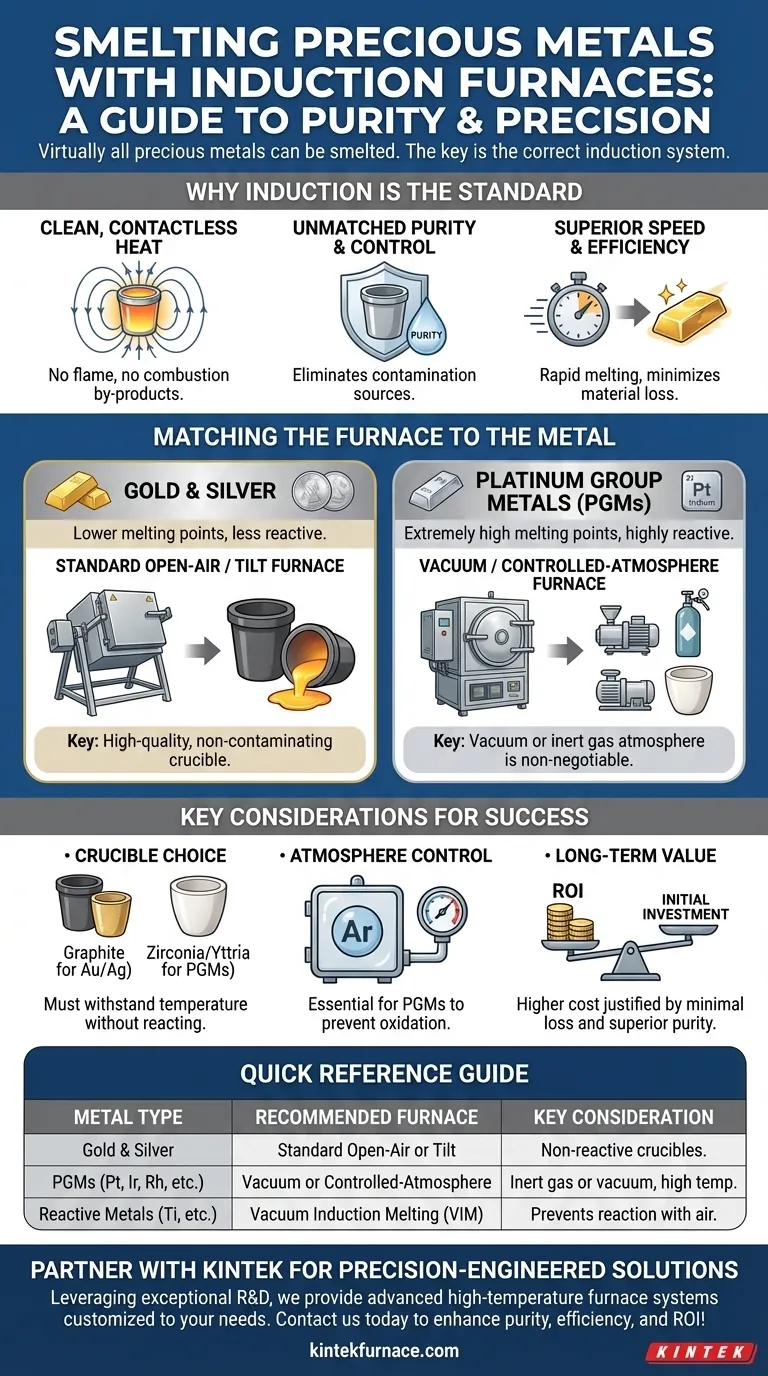

Why Induction is the Standard for Precious Metals

Induction heating is fundamentally different from traditional fuel-fired furnaces. Understanding this difference is key to appreciating why it is the preferred technology for handling valuable and sensitive materials.

The Principle of Clean, Contactless Heat

An induction furnace uses a powerful alternating magnetic field to induce electrical currents (called eddy currents) directly within the metal itself.

This process generates rapid, precise, and uniform heat from the inside out. Crucially, there is no flame, no combustion by-products, and no contact between the heat source and the metal, eliminating major sources of contamination.

Unmatched Purity and Control

For precious metals, even trace amounts of impurities can dramatically reduce value. Induction heating offers unparalleled protection against this.

Because the furnace crucible can be made from non-reactive ceramic materials and the heat is generated within the metal, there is no contamination from fuel, electrodes, or atmospheric gases. This results in a cleaner melt and a higher-purity final product.

Superior Speed and Efficiency

Induction furnaces melt metals with exceptional speed. A small batch of gold can be melted in minutes.

This rapid melting minimizes the time the molten metal is exposed to the atmosphere, reducing the chance for oxidation and minimizing the loss of valuable material through vaporization, a significant concern with high-value metals.

Matching the Furnace to the Metal

While the heating principle is the same, the specific furnace configuration must be matched to the metal's properties, particularly its melting point and reactivity with air.

Gold and Silver

Gold and silver are relatively straightforward. Their lower melting points and lower reactivity mean they can be processed effectively in standard, open-air tilt furnaces or simple lift-coil systems.

The main consideration is using a high-quality, non-contaminating crucible (like graphite clay or silicon carbide) to maintain purity.

Platinum Group Metals (PGMs)

The platinum group metals (PGMs) are far more demanding. This group includes platinum, iridium, rhodium, and palladium, all of which have extremely high melting points.

At these temperatures, the metals become much more reactive to oxygen in the air. Melting them in an open furnace would lead to significant oxidation and material loss. Therefore, PGMs require a vacuum induction furnace or a system that allows melting under a protective, inert gas atmosphere (like argon).

Reactive and Specialty Metals

The same principle applies to other highly reactive metals, such as titanium or zirconium. While not "precious" in the same way as gold, they are high-value specialty materials.

Processing them absolutely requires a vacuum induction melting (VIM) furnace to prevent them from reacting with oxygen and nitrogen, which would ruin the alloy. This demonstrates the critical role of the furnace's environment, not just its heat source.

Understanding the Key Considerations

Choosing an induction system involves more than just identifying the metal. You must consider the entire process to ensure success and protect your investment.

The Critical Role of the Crucible

The crucible contains the molten metal and must withstand extreme temperatures without reacting with the metal. For gold and silver, graphite crucibles are common.

For high-temperature PGMs, more advanced ceramic crucibles made of materials like zirconia or yttria are necessary to prevent failure and contamination at temperatures exceeding 2000°C (3632°F).

Controlled Atmosphere is Non-Negotiable for PGMs

To reiterate a crucial point: you cannot successfully smelt most platinum group metals without environmental control.

Attempting to melt platinum or iridium in an open-air induction furnace will result in poor quality and significant financial loss. A vacuum or inert gas backfill is an essential part of the system for these materials.

Initial Investment vs. Long-Term Value

Induction furnace systems represent a significant capital investment compared to simple gas-fired torches or furnaces.

However, for serious precious metal processing, the higher initial cost is justified by minimal metal loss, superior purity, faster processing times, and enhanced operator safety, delivering a clear return on investment.

Making the Right Choice for Your Application

Your choice of induction system should be driven by the specific metals you intend to process and your primary operational goal.

- If your primary focus is smelting gold and silver: A standard open-air or tilt induction furnace provides an excellent balance of speed, purity, and efficiency.

- If your primary focus is processing Platinum Group Metals (PGMs): A vacuum induction furnace or a controlled-atmosphere system is mandatory to handle the high temperatures and prevent oxidation.

- If your primary focus is maximizing purity across all metals: An induction system, particularly one with vacuum capabilities, is the definitive choice for eliminating contamination from all external sources.

Ultimately, investing in the right induction technology empowers you to protect the value of your material through precise and repeatable control.

Summary Table:

| Metal Type | Recommended Furnace Type | Key Considerations |

|---|---|---|

| Gold & Silver | Standard Open-Air or Tilt Furnace | Lower melting points, use non-reactive crucibles for purity |

| Platinum Group Metals (e.g., Platinum, Iridium) | Vacuum or Controlled-Atmosphere Furnace | High melting points, requires inert gas or vacuum to prevent oxidation |

| Reactive Metals (e.g., Titanium) | Vacuum Induction Melting (VIM) Furnace | Prevents reaction with air, essential for high-value materials |

Protect your valuable materials with precision-engineered solutions from KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental needs, whether you're smelting gold, silver, or demanding platinum group metals. Contact us today to discuss how our induction furnaces can enhance purity, efficiency, and ROI for your operations!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity