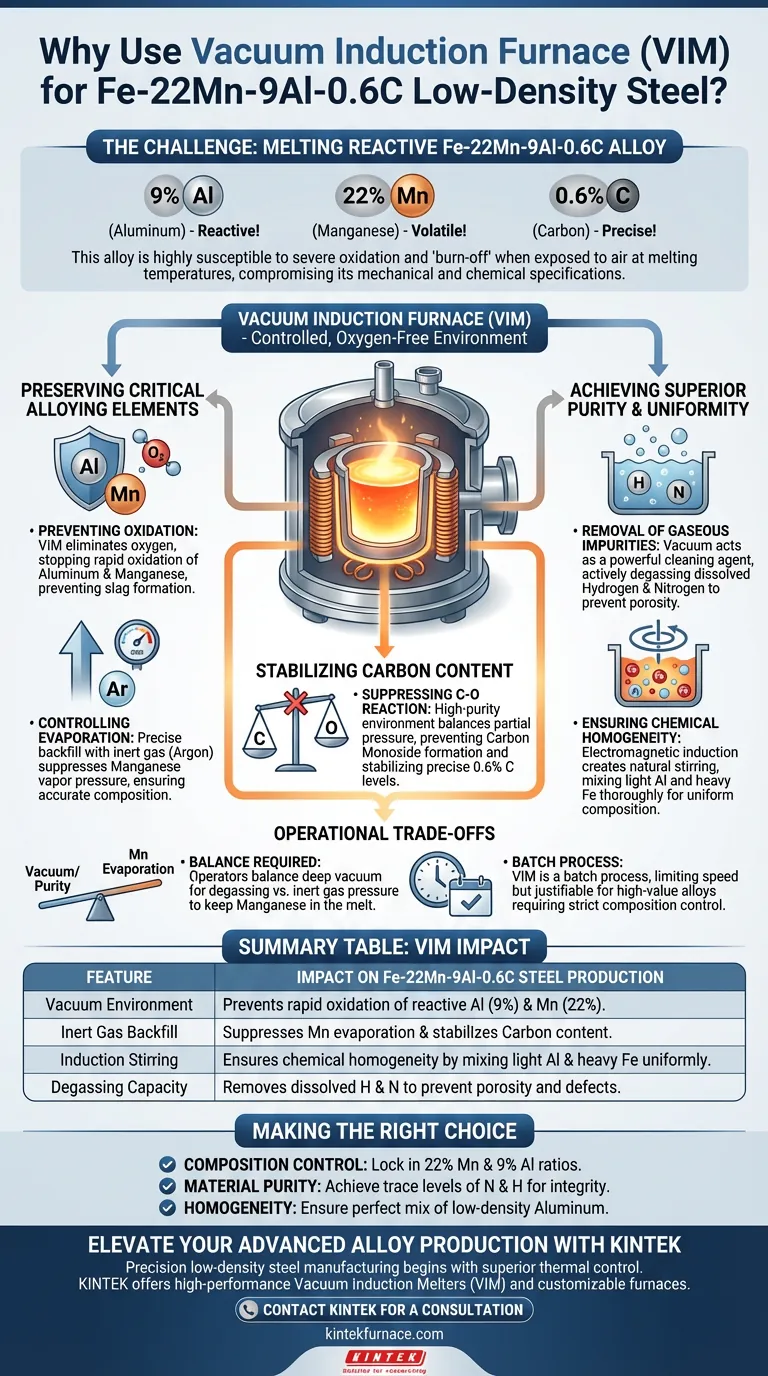

A vacuum induction furnace (VIM) is deployed specifically to create an oxygen-free, controlled environment essential for melting Fe-22Mn-9Al-0.6C low-density steel. Because this alloy contains high concentrations of reactive aluminum and manganese, this process is non-negotiable to prevent severe oxidation, minimize impurity levels, and ensure the chemical composition remains uniform throughout the ingot.

The presence of 9% aluminum and 22% manganese makes this steel highly susceptible to degradation when exposed to air at melting temperatures. A vacuum induction furnace is the definitive solution to prevent the "burn-off" of these critical elements, ensuring the final material meets its precise mechanical and chemical specifications.

Preserving Critical Alloying Elements

The primary challenge in melting Fe-22Mn-9Al-0.6C is the high reactivity of its defining components.

Preventing Oxidation of Aluminum and Manganese

Aluminum and manganese are chemically active elements that react instantly with oxygen at high temperatures. Without a vacuum environment, these elements would oxidize rapidly, forming unwanted inclusions (slag) rather than integrating into the steel matrix. VIM eliminates atmospheric oxygen, ensuring these expensive alloying elements are retained in the melt.

Controlling Volatility and Evaporation

Manganese has a high vapor pressure, meaning it can evaporate easily during melting. The vacuum induction process allows for precise atmospheric control, often utilizing a backfill of inert gas (like Argon) to suppress evaporation. This ensures the 22% manganese target is hit accurately without requiring excessive raw material compensation.

Achieving Superior Purity and Uniformity

Beyond saving alloying elements, the VIM process significantly enhances the quality of the steel's microstructure.

Removal of Gaseous Impurities

The vacuum environment acts as a powerful cleaning agent. It actively facilitates the removal of dissolved gases such as nitrogen and hydrogen from the molten bath. This "degassing" prevents porosity and defects in the solidified steel, which is critical for maintaining high-density mechanical properties.

Ensuring Chemical Homogeneity

Electromagnetic induction creates a natural stirring action within the molten metal. This constant movement ensures that the lighter aluminum and heavier iron mix thoroughly. This results in a chemically uniform composition throughout the ingot, preventing segregation that could lead to weak points in large-volume alloys.

Stabilizing Carbon Content

For an alloy relying on 0.6% carbon for strength, maintaining precise carbon levels is difficult but essential.

Suppressing the Carbon-Oxygen Reaction

In standard melting, carbon can react with oxygen to form carbon monoxide gas, leading to a loss of carbon content. By maintaining a high-purity environment—often supplemented by argon at specific pressures (e.g., 30,000 Pa)—the furnace suppresses this reaction. This balances the partial pressure above the melt, stabilizing the carbon content and preventing the intrusion of impurities.

Understanding the Operational Trade-offs

While VIM is technically superior for this alloy, it introduces specific constraints that must be managed.

Managing Mn Evaporation vs. Degassing

There is a delicate balance between pulling a deep vacuum for purity and maintaining enough pressure to keep manganese in the melt. If the vacuum is too high, manganese evaporation increases; if it is too low, degassing is less effective. Operators must carefully control pressure (often using Argon) to navigate this trade-off.

Production Throughput Limits

VIM is inherently a batch process, distinct from continuous casting methods used for standard steels. This limits the speed of production and increases the cost per ton. It is justifiable only for high-value alloys like Fe-22Mn-9Al-0.6C where composition control is paramount.

Making the Right Choice for Your Goal

The use of a vacuum induction furnace is a strategic decision based on the strict requirements of low-density steel production.

- If your primary focus is Composition Control: Rely on VIM to lock in the 22% Mn and 9% Al ratios, preventing the oxidative losses that occur in open-air melting.

- If your primary focus is Material Purity: Use VIM to actively degas the melt, reducing nitrogen and hydrogen to trace levels for superior structural integrity.

- If your primary focus is Homogeneity: Leverage the electromagnetic stirring inherent in induction heating to ensure the low-density aluminum is perfectly mixed with the iron matrix.

Ultimately, for Fe-22Mn-9Al-0.6C steel, the vacuum induction furnace is not just a heating tool; it is a chemical processing vessel that guarantees the integrity of the alloy design.

Summary Table:

| Feature | Impact on Fe-22Mn-9Al-0.6C Steel Production |

|---|---|

| Vacuum Environment | Prevents rapid oxidation of reactive Aluminum (9%) and Manganese (22%). |

| Inert Gas Backfill | Suppresses Manganese evaporation and stabilizes Carbon content. |

| Induction Stirring | Ensures chemical homogeneity by mixing light Al and heavy Fe uniformly. |

| Degassing Capacity | Removes dissolved Hydrogen and Nitrogen to prevent porosity and defects. |

Elevate Your Advanced Alloy Production with KINTEK

Precision in low-density steel manufacturing begins with superior thermal control. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum Induction Melters (VIM), CVD systems, and customizable lab high-temp furnaces designed to handle the most reactive alloys.

Whether you are refining Fe-Mn-Al-C steels or developing next-generation materials, our systems provide the oxygen-free environment and electromagnetic precision you need to ensure material integrity.

Ready to optimize your melting process? Contact KINTEK today for a consultation

Visual Guide

References

- Yihao Zhou, Dong Han. Secondary Phase Precipitation in Fe-22Mn-9Al-0.6C Low-Density Steel during Continuous Cooling Process. DOI: 10.3390/ma17030631

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- Why is temperature control important in induction furnaces? Ensure Consistent Quality and Efficiency

- What is induction shrink-fitting and how does it work? Master Precision Assembly with Induction Heating

- Why is an argon atmosphere maintained during VIM of Chromium-Silicon alloys? Prevent High Chromium Loss

- How does an IGBT Vacuum Induction Melting Furnace operate? Achieve Ultra-High-Purity Metal Melting

- What is an IGBT induction melting furnace? Achieve Faster, Cleaner, and More Efficient Metal Melting

- What is vacuum arc melting (VAR) and what is its primary purpose? Achieve Superior Metal Purity and Performance

- What are some common applications of vacuum casting furnaces in the aerospace industry? Discover Critical Uses for High-Performance Components

- How does frequency affect the heating efficiency in an induction furnace? Optimize Your Process with the Right Frequency