In the aerospace industry, vacuum casting furnaces are primarily used to produce mission-critical components that must withstand extreme conditions. These include parts like turbine blades, engine components, and key structural elements made from advanced, heat-resistant superalloys.

The core value of a vacuum furnace is not merely melting metal, but creating a pristine, controlled environment. This vacuum prevents atmospheric contamination, which is the only way to guarantee the precise metallurgical purity and structural integrity required for high-performance aerospace alloys.

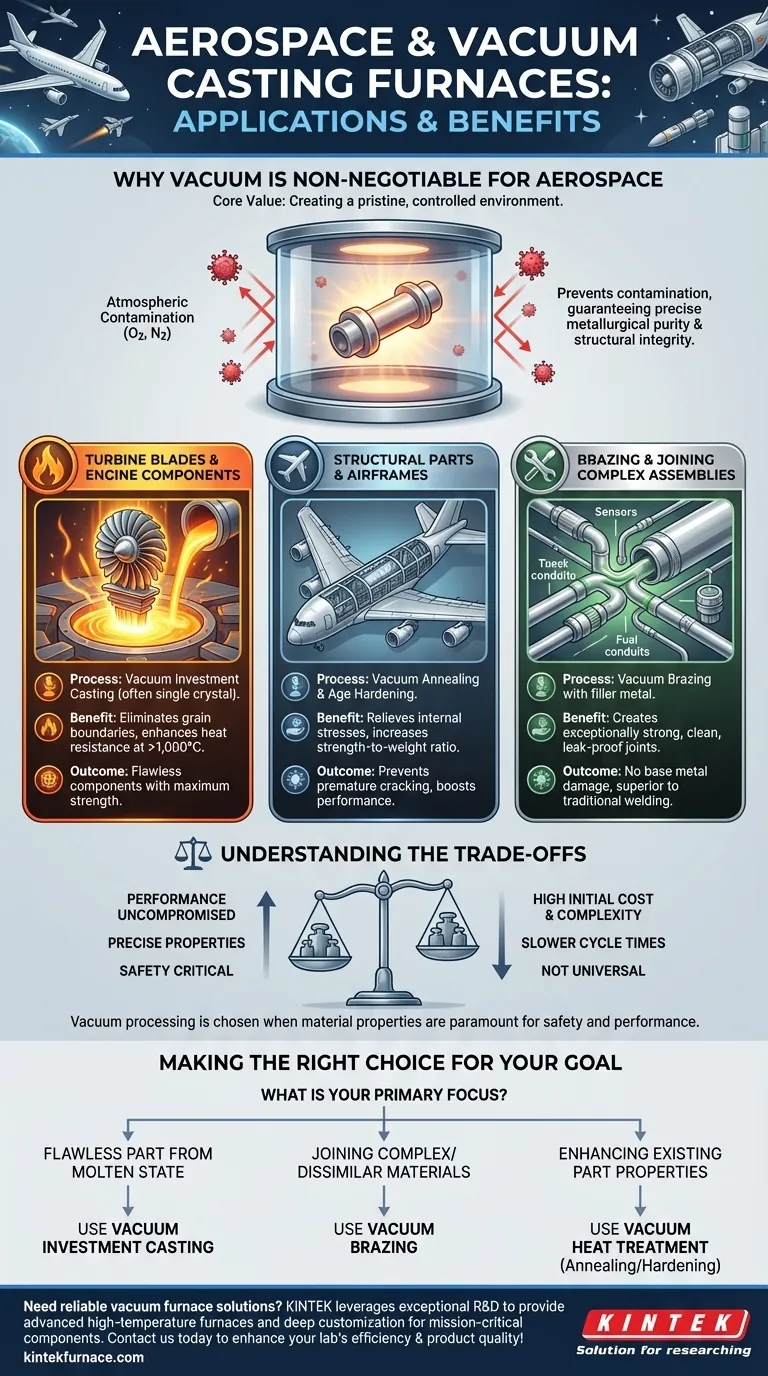

Why Vacuum is Non-Negotiable for Aerospace

The decision to use a vacuum furnace is driven by the unforgiving performance demands of aerospace engineering. The "vacuum" itself is the key enabling technology for processing the advanced materials used in modern aircraft and spacecraft.

Eliminating Atmospheric Contamination

At the high temperatures required for casting and heat-treating superalloys, reactive metals are extremely vulnerable to contamination from oxygen and nitrogen in the air.

This contamination creates oxides and nitrides within the metal's structure, leading to brittleness, reduced strength, and a lower melting point—failures that are catastrophic in an aerospace context. A vacuum removes these reactive gases, ensuring the final alloy is pure and performs exactly as designed.

Achieving Precise Metallurgical Properties

Aerospace components require specific properties like high tensile strength, fatigue resistance, and creep resistance at extreme temperatures.

Vacuum furnaces provide the controlled environment needed for processes like annealing (softening metal), hardening (increasing strength), and tempering. These heat treatments refine the grain structure of the alloy without introducing impurities, locking in the desired mechanical characteristics.

Processing Advanced Superalloys

Materials like nickel-based superalloys are essential for the hot sections of jet engines because they retain their strength at temperatures approaching their melting point.

These alloys are highly reactive and can only be processed correctly in a vacuum. The vacuum environment is crucial for both vacuum casting (shaping the part) and subsequent vacuum heat treatments that optimize its final properties.

Key Applications and Processes

While "casting" is a primary use, vacuum furnaces facilitate a range of thermal processes essential for manufacturing various aerospace components.

Turbine Blades and Engine Components

This is the most common and critical application. Turbine blades spin at tens of thousands of RPM in environments exceeding 1,000°C.

Vacuum investment casting is used to produce these parts, often as a single crystal, to eliminate grain boundaries that would be points of failure. This process creates a flawless component with maximum strength and heat resistance.

Structural Parts and Airframes

Components within the airframe require an exceptional strength-to-weight ratio. While not always cast, these parts often undergo treatment in a vacuum furnace.

Vacuum annealing is used to relieve internal stresses created during manufacturing, preventing premature cracking. Vacuum age hardening is another process used to significantly increase the strength of aluminum and titanium alloys after they have been formed.

Brazing and Joining Complex Assemblies

Aerospace systems rely on complex assemblies of tubes, sensors, and conduits for fuel and hydraulics. Joining these parts is a major challenge.

Vacuum brazing uses a filler metal to join components in the clean, controlled furnace environment. This produces an exceptionally strong, clean, and leak-proof joint without weakening the base metals, which is impossible to achieve with traditional welding or torch brazing.

Understanding the Trade-offs

While indispensable, vacuum furnace technology is not without its challenges and is reserved for applications where performance cannot be compromised.

High Initial Cost and Complexity

Vacuum furnaces are a significant capital investment. They are complex machines that require specialized knowledge for operation, programming, and maintenance, adding to the operational overhead.

Slower Process Cycle Times

Achieving a deep vacuum, running a precise heating and cooling profile, and returning the chamber to atmospheric pressure is an inherently slow process. Cycle times are significantly longer compared to conventional open-air furnaces, which impacts throughput.

Not a Universal Solution

For less critical components where the absolute highest material purity is not required, traditional casting and heat-treating methods can be more cost-effective. Vacuum processing is specifically chosen when the material properties are paramount and directly tied to safety and performance.

Making the Right Choice for Your Goal

The specific vacuum process you use depends entirely on your end goal.

- If your primary focus is creating a flawless part from a molten state: Use vacuum investment casting, especially for single-crystal turbine blades and other components that cannot have internal defects.

- If your primary focus is joining complex or dissimilar materials: Use vacuum brazing to create strong, pure joints in critical assemblies like fuel lines or heat exchangers without damaging the parent materials.

- If your primary focus is enhancing the properties of an existing part: Use vacuum heat treatment (like annealing or hardening) to optimize the strength, ductility, and stress resistance of critical structural components.

Ultimately, mastering vacuum furnace technology is fundamental to producing aerospace components that can reliably perform in the most extreme conditions imaginable.

Summary Table:

| Application | Key Process | Benefits |

|---|---|---|

| Turbine Blades | Vacuum Investment Casting | Eliminates grain boundaries, enhances heat resistance |

| Engine Components | Vacuum Casting & Heat Treatment | Prevents contamination, improves strength |

| Structural Parts | Vacuum Annealing & Age Hardening | Relieves stress, increases strength-to-weight ratio |

| Complex Assemblies | Vacuum Brazing | Creates strong, leak-proof joints without base metal damage |

Need reliable vacuum furnace solutions for your aerospace projects? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure we meet your unique experimental needs, delivering precise metallurgical purity and performance for mission-critical components. Contact us today to discuss how we can enhance your lab's efficiency and product quality!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Induction Melting Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety