The utilization of a vacuum drying system is critical for treating precursor powders of Boron Nitride @ Carbon (BN@C) composites to safely remove residual methanol solvents. By operating at reduced pressure, this method allows for effective drying at low temperatures, which is necessary to protect the chemical and structural integrity of the sensitive precursor components.

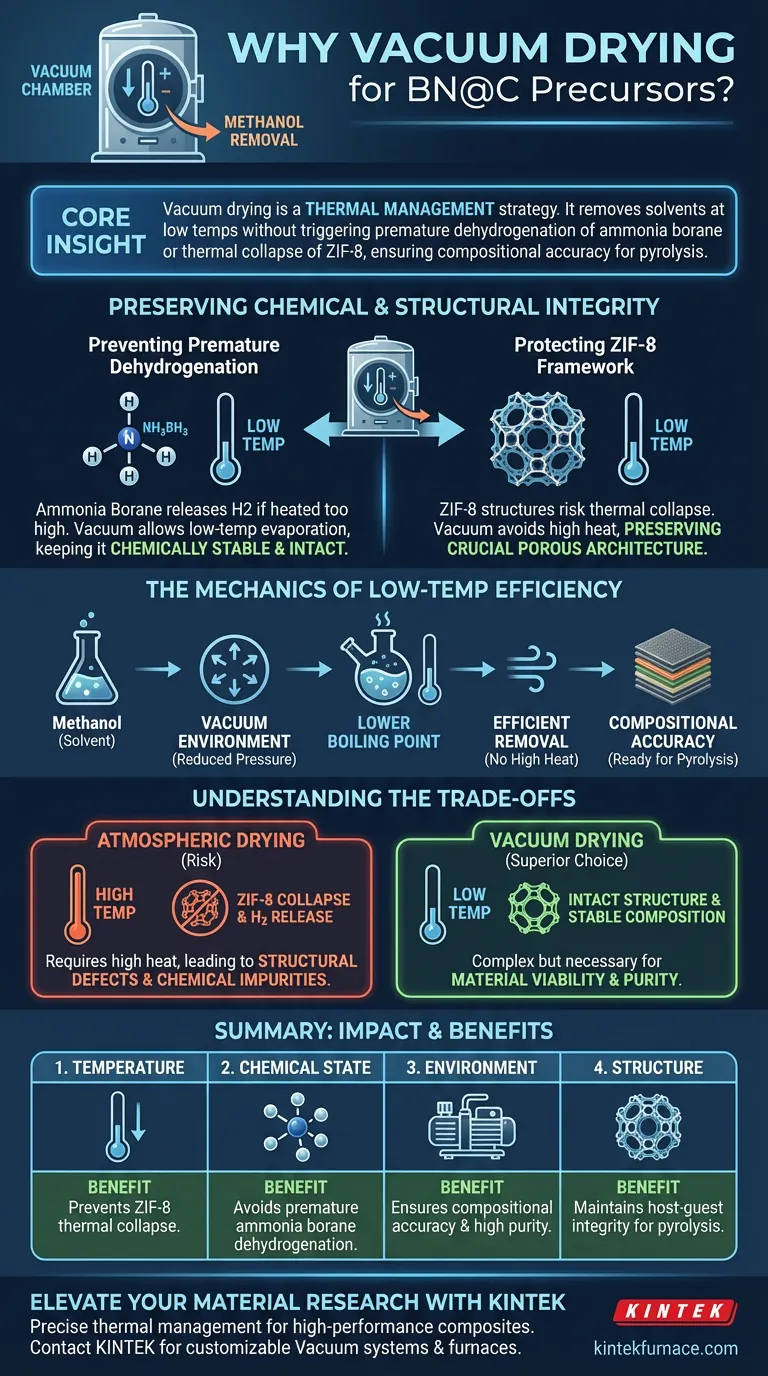

Core Insight: Vacuum drying is not merely about removing moisture; it is a thermal management strategy. It permits the removal of solvents without triggering the premature dehydrogenation of ammonia borane or causing thermal collapse of the ZIF-8 framework, ensuring the material is compositionally accurate before the pyrolysis stage.

Preserving Chemical and Structural Integrity

The preparation of BN@C composites involves delicate chemical precursors that are highly sensitive to thermal stress. The vacuum drying process addresses two specific risks inherent to these materials.

Preventing Premature Dehydrogenation

The precursor powder typically contains ammonia borane, a compound that releases hydrogen when heated.

If the drying temperature is too high, ammonia borane will undergo premature dehydrogenation before the intended pyrolysis stage. Vacuum drying allows the solvent to evaporate at temperatures low enough to keep the ammonia borane chemically stable and intact.

Protecting the ZIF-8 Framework

The composite precursor often utilizes ZIF-8 (Zeolitic Imidazolate Framework-8) as a structural host.

ZIF-8 structures are susceptible to thermal damage and framework collapse if exposed to excessive heat during the drying phase. By avoiding high-temperature atmospheric drying, the vacuum system preserves the crucial porous architecture of the ZIF-8, which is essential for the final properties of the BN@C composite.

The Mechanics of Low-Temperature Efficiency

The physical principles of vacuum drying provide the "how" behind the preservation of these materials.

Lowering Solvent Boiling Points

The primary solvent used in this synthesis is often methanol.

In a vacuum environment, the ambient pressure is significantly reduced, which directly lowers the boiling point of the methanol. This allows the solvent to be removed efficiently and rapidly without requiring the high thermal energy inputs associated with standard atmospheric ovens.

Ensuring Compositional Accuracy

The ultimate goal of the precursor stage is to create a reliable foundation for the subsequent pyrolysis step.

By ensuring that solvents are removed without altering the chemical state of the ammonia borane or the physical state of the ZIF-8, the process guarantees compositional accuracy. The material entering the furnace is exactly what was calculated, leading to predictable and high-quality BN@C composites.

Understanding the Trade-offs

While vacuum drying is the superior choice for these specific precursors, it is helpful to understand the limitations of alternative methods to appreciate why this specific route is chosen.

The Risk of Atmospheric Heating

Standard atmospheric drying relies on heat to drive off solvents. To remove methanol effectively at atmospheric pressure, temperatures must be raised significantly.

This elevation in temperature creates an immediate conflict: the heat required to dry the powder is sufficient to degrade the ZIF-8 framework or trigger the release of hydrogen from ammonia borane. Therefore, atmospheric drying introduces a high risk of structural defects and chemical impurities in the final product.

Equipment Complexity

Vacuum drying systems are more complex and costly than standard drying ovens. They require vacuum pumps, precise pressure seals, and maintenance of a specific low-pressure environment. However, for BN@C precursors, this added complexity is a necessary investment to ensure material viability.

Making the Right Choice for Your Goal

When preparing precursors for advanced composites like BN@C, your drying method dictates the success of your downstream processing.

- If your primary focus is Chemical Stability: Use vacuum drying to prevent the early release of hydrogen from ammonia borane, preserving the stoichiometry for the pyrolysis phase.

- If your primary focus is Structural Integrity: Rely on the reduced temperature requirements of vacuum drying to prevent thermal collapse of the ZIF-8 porous framework.

The precision of your drying environment determines the purity and performance of your final composite material.

Summary Table:

| Feature | Vacuum Drying Impact | Benefit for BN@C Precursors |

|---|---|---|

| Temperature | Lowers methanol boiling point | Prevents ZIF-8 framework thermal collapse |

| Chemical State | Reduced thermal stress | Avoids premature ammonia borane dehydrogenation |

| Environment | Controlled low-pressure | Ensures compositional accuracy and high purity |

| Structure | Preservation of porosity | Maintains host-guest integrity for pyrolysis |

Elevate Your Material Research with KINTEK

Precise thermal management is the difference between a high-performance composite and a failed experiment. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum systems, Muffle, Tube, Rotary, and CVD furnaces—all fully customizable to your lab's unique research needs.

Ensure the structural and chemical integrity of your precursors with our industry-leading solutions.

Ready to optimize your synthesis process? Contact KINTEK today to consult with our technical specialists!

Visual Guide

References

- Carlos A. Castilla-Martinez, Umit B. Demirci. A boron nitride–carbon composite derived from ammonia borane and ZIF-8 with promises for the adsorption of carbon dioxide. DOI: 10.1039/d4nj00643g

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the disadvantage of graphite furnace? Key Trade-offs for Ultra-Trace Analysis

- How do vacuum pumps and high-purity nitrogen gas protect steel? Ensure Precise Austenitization for Accurate Results

- What support is available for those new to Low Pressure Vacuum Carburizing? Master LPVC with Expert Guidance

- What are the advantages of vacuum furnaces over traditional furnaces? Achieve Superior Purity and Control

- How is a laboratory vacuum drying oven utilized in the production of shape-stabilized phase change materials?

- Why is a shell roasting furnace used prior to the pouring of C1023 superalloys? Expert Guide to Casting Integrity

- How are vacuum experimental furnaces used in research and laboratory settings? Unlock Precision in Materials Science

- What is the purpose of using a vacuum oven for h-NCM(OH)2? Optimize Your Cathode Material Research