For those new to Low Pressure Vacuum Carburizing (LPVC), the primary support available is direct consultation with an R&D Engineering team. This expert guidance is specifically focused on two critical areas: developing custom process recipes and providing comprehensive team training to ensure a successful implementation of the technology.

While the direct answer involves consultation and training, the deeper reality is that successfully adopting LPVC is not about buying equipment—it's about mastering a sophisticated process. This expert support is the bridge between acquiring the technology and achieving its full potential for quality and efficiency.

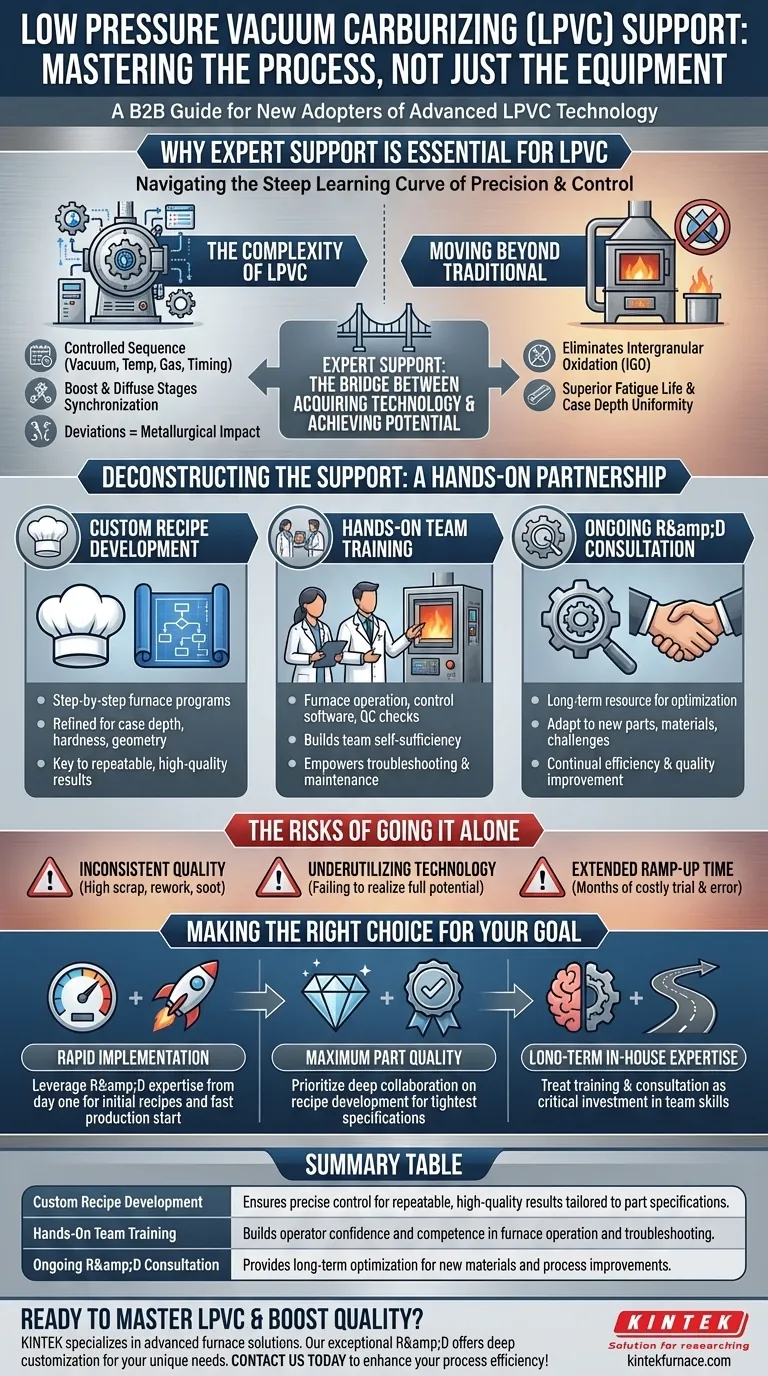

Why Expert Support is Essential for LPVC

Low Pressure Vacuum Carburizing represents a significant technological leap from traditional atmospheric carburizing. Its precision and control are its greatest strengths, but they also create a steep learning curve that makes expert guidance a necessity, not a luxury.

The Complexity of the LPVC Process

The LPVC process involves a highly controlled sequence of steps within a vacuum furnace. Variables such as vacuum level, temperature, gas flow rates, and the precise timing of carburizing "boost" and "diffuse" stages must be perfectly synchronized.

Even small deviations can significantly impact the final metallurgical properties of the component. Expert support helps you navigate this complexity from the start.

Moving Beyond Traditional Methods

Unlike atmospheric carburizing, LPVC eliminates the risk of intergranular oxidation (IGO), resulting in superior fatigue life and component performance. It also delivers exceptional case depth uniformity, even on complex geometries.

However, achieving these results requires a completely different operational mindset and skillset. The support system is designed to manage this transition, ensuring your team can leverage the new capabilities effectively.

Deconstructing the Support: What to Expect

The support offered goes far beyond a simple user manual. It's a hands-on partnership designed to integrate the LPVC process into your specific manufacturing environment.

Custom Recipe Development

A process "recipe" is a detailed, step-by-step program that controls the furnace for a specific part and material to achieve a desired outcome.

Engineers work with you to develop and refine these recipes based on your required case depth, surface hardness, core properties, and part geometry. This customization is the key to repeatable, high-quality results.

Hands-On Team Training

Effective training ensures your operators and engineers are confident and competent in running the equipment. This typically covers the furnace operation, control software, routine maintenance, and quality control checks.

The goal is to build self-sufficiency within your team, empowering them to manage the process and troubleshoot minor issues independently.

Ongoing R&D Consultation

The initial setup is just the beginning. Having access to an R&D team provides a long-term resource for process optimization.

As you introduce new parts, materials, or face unique challenges, this partnership allows you to adapt and refine your processes, continually improving efficiency and quality.

The Risks of Going It Alone

Attempting to implement LPVC without specialized support can lead to significant and costly setbacks. Understanding these risks highlights the value of a structured implementation plan.

Risk of Inconsistent Quality

Without professionally developed recipes, the initial trial-and-error period can result in high rates of scrap and rework. Issues like excessive soot formation, incorrect case depths, or inconsistent hardness are common pitfalls that expert guidance helps you avoid.

Underutilizing the Technology

The most significant risk is investing in advanced technology but only using a fraction of its capability. Without understanding how to optimize recipes, teams often stick to a single, non-ideal process, failing to realize the full quality and efficiency gains LPVC offers.

Extended Ramp-Up Time

Developing a robust and stable LPVC process from scratch can take months of experimentation, consuming valuable time and resources. Expert support drastically shortens this learning curve, allowing you to move into full-scale, profitable production much faster.

Making the Right Choice for Your Goal

Engaging with expert support is a strategic decision. Aligning that support with your primary objective will maximize its value.

- If your primary focus is rapid implementation: Leverage the R&D team's expertise from day one to develop initial recipes and get your system into production as quickly as possible.

- If your primary focus is achieving maximum part quality: Prioritize deep collaboration on recipe development to meet the tightest metallurgical specifications and ensure absolute process consistency.

- If your primary focus is building long-term in-house expertise: Treat the training and consultation as a critical investment in your team, ensuring they have the skills to optimize and adapt the process for future needs.

Leveraging expert support transforms the adoption of LPVC from a technical challenge into a strategic manufacturing advantage.

Summary Table:

| Support Type | Key Benefits |

|---|---|

| Custom Recipe Development | Ensures precise control for repeatable, high-quality results tailored to part specifications. |

| Hands-On Team Training | Builds operator confidence and competence in furnace operation and troubleshooting. |

| Ongoing R&D Consultation | Provides long-term optimization for new materials and process improvements. |

Ready to master Low Pressure Vacuum Carburizing and boost your manufacturing quality? KINTEK specializes in advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems. With our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique needs. Contact us today to discuss how our expert support can enhance your process efficiency and deliver superior results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties